Precise Positioning Ultrasonic Motor Excited by Dual Vibrator Combined Ultrasonic Vibrator

An ultrasonic vibrator, ultrasonic motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of small output force, reduce resonance operating frequency, etc. The effect of reducing running error, eliminating return error and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

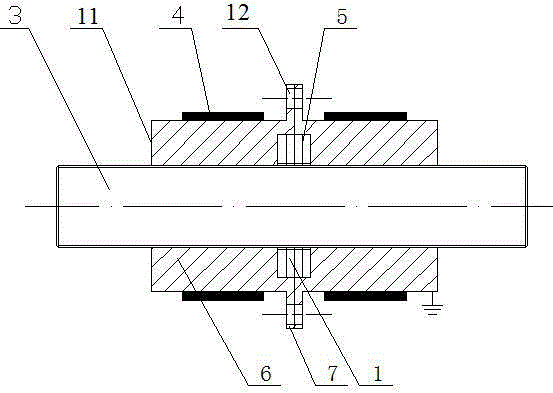

[0032] Specific implementation mode one: see Figure 1 to Figure 5 , the precise positioning ultrasonic motor excited by the dual vibrator combined ultrasonic vibrator, the precise positioning ultrasonic motor excited by the dual vibrator combined ultrasonic vibrator mainly includes a threaded output shaft 3, a linear actuator 5, a plurality of exciting elements 4 and two An ultrasonic vibrator 11, the ultrasonic vibrator 11 is a columnar elastic body, the ultrasonic vibrator 11 includes a vibrated main body 6 and a combined locking end 7, the combined locking end 7 is located at one end of the vibrated main body 6 and the two are integrated, combined The locking end 7 is a protruding disc-shaped structure, and the center of the other end of the excited body 6 is provided with a threaded hole 9, combined with the center of the locking end 7, a cylindrical concave cavity 8 is provided for the built-in installation of the linear actuator 5, threaded The hole 9 is coaxial with th...

specific Embodiment approach 2

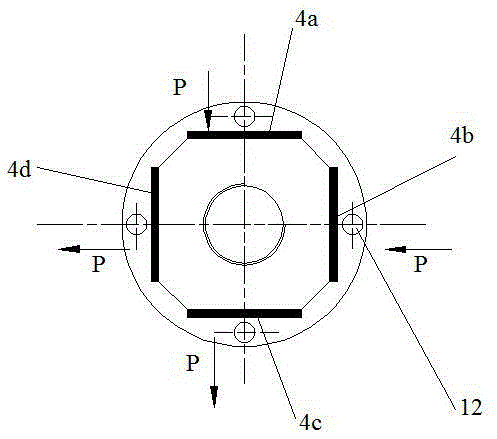

[0035] Specific embodiment 2: The precise positioning ultrasonic motor excited by the double vibrator combined ultrasonic vibrator described in the specific embodiment 1, the outer peripheral side of the excited main body 6 is uniformly processed with at least four structurally symmetrical square orientations. flat sides (eg figure 2 and image 3 ) or groove ( Figure 4 and Figure 5 ), the number of vibration elements 4 is consistent with the number of flat sides or grooves, and one vibration element 4 is fixed on each flat side or in the groove (the vibration element 4 is fixed by cold welding or epoxy resin glue on the flat side or in the groove, making the structure of the ultrasonic vibrator 11 more compact).

specific Embodiment approach 3

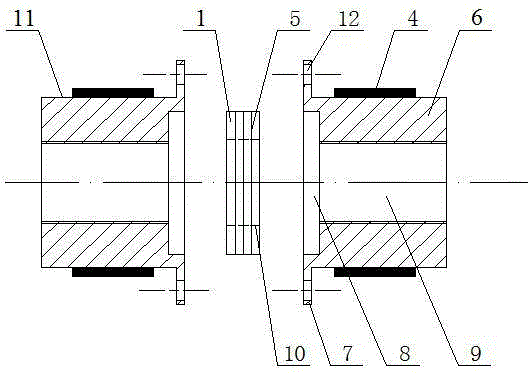

[0036] Specific implementation mode three: as Figure 6~Figure 11 As shown, the precise positioning ultrasonic motor excited by the dual vibrator combined ultrasonic vibrator mainly includes a threaded output shaft 3, a linear actuator 5, and a plurality of exciting elements 4 , two threaded auxiliary driving elements 2 and two ultrasonic vibrators 11, the ultrasonic vibrator 11 is a cylindrical elastic body, the ultrasonic vibrator 11 includes an excited main body 6 and a combined locking end 7, and the combined locking end 7 is located on the excited main body 6 One end and the two are integrated, the combined locking end 7 is a protruding disc-shaped structure, the center of the other end of the excitation main body 6 is provided with a threaded auxiliary driving element mounting hole, and the center of the combined locking end 7 is provided with a cylindrical concave cavity 8, For the built-in installation of the linear actuator 5, the mounting hole of the threaded auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com