Double membrane slow release fertilizer containing humic acid and preparation method thereof

A technology of slow-release fertilizer and humic acid, which is applied in fertilizer forms, fertilization devices, fertilizer mixtures, etc., can solve the problems of long degradation period, high price, limited application and promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

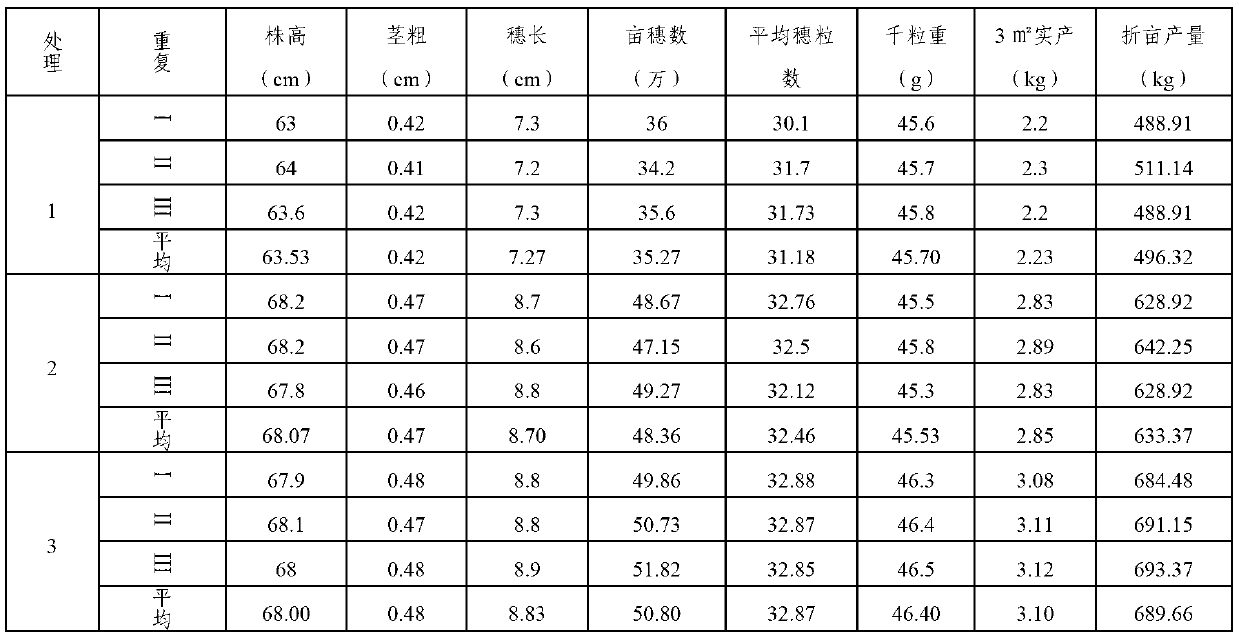

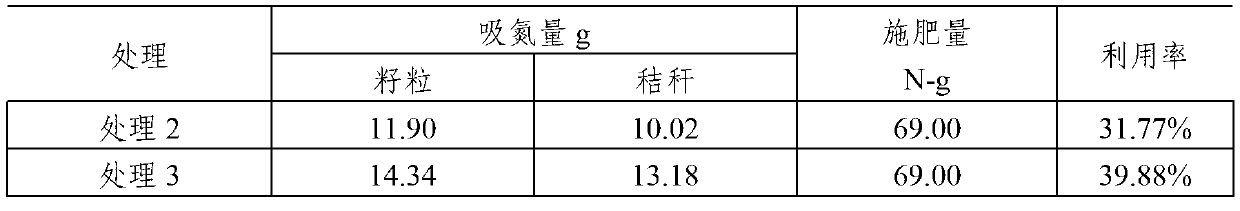

Examples

Embodiment 1

[0046] Embodiment 1: the preparation method of the double-film slow-release fertilizer containing humic acid

[0047] 1. Preparation of the first layer of film material (modified gelatin composite solution), taking 100 kg per production as an example.

[0048] (1) Add 15 kg of water and 2.5 kg of gelatin into the reaction kettle A, soak for 30 minutes, then stir and heat up to 60-70°C, and then add 20 kg of urea;

[0049] (2) Add 36 kg of water, 20 kg of ferrous sulfate, 1.5 kg of zinc sulfate, 1.5 kg of magnesium sulfate, 0.5 kg of manganese sulfate, 0.5 kg of boric acid, and 2.5 kg of ammonium citrate in the reaction kettle B, stir and heat to 50-60°C;

[0050] (3) Pour the liquid in Reactor B into Reactor A and keep stirring for 2 hours to make a modified gelatin compound solution for later use.

[0051] 2. Preparation of the second layer of membrane material (ultrafine activated humic acid powder). Take each production of 100 kg as an example:

[0052] Mix 99 kg of pre...

Embodiment 2

[0057] Embodiment 2: the preparation method of the double-film slow-release fertilizer containing humic acid

[0058] 1. Preparation of the first layer of film material (modified gelatin composite solution). Take each production of 100 kg as an example.

[0059] (1) Add 15 kg of water and 2 kg of gelatin into the reaction kettle A, soak for 30 minutes, then stir and heat up to 60-70°C, and then add 40 kg of urea;

[0060] (2) Add 33 kg of water, 5 kg of ferrous sulfate, 1 kg of zinc sulfate, 1 kg of magnesium sulfate, 1 kg of manganese sulfate, 1 kg of boric acid, and 2 kg of ammonium citrate in the reaction kettle B, stir and heat to 50-60°C;

[0061] (3) Pour the liquid in Reactor B into Reactor A and keep stirring for 2 hours to make a modified gelatin compound solution for later use.

[0062] 2. Preparation of the second layer of membrane material (ultrafine activated humic acid powder), taking 100 kg per production as an example:

[0063] Mix 99 kg of pre-crushed 200-...

Embodiment 3

[0069] Embodiment 3: the preparation method of the double-film slow-release fertilizer containing humic acid

[0070] 1. Preparation of the first layer of film material (modified gelatin composite solution). Take each production of 100 kg as an example.

[0071] (1) Add 15 kg of water and 2 kg of gelatin into the reaction kettle A, soak for 30 minutes, then stir and heat up to 60-70°C, and then add 40 kg of urea;

[0072] (2) Add 33 kg of water, 5 kg of ferrous sulfate, 1 kg of zinc sulfate, 1 kg of magnesium sulfate, 1 kg of manganese sulfate, 1 kg of boric acid, and 2 kg of ammonium citrate in the reaction kettle B, stir and heat to 50-60°C;

[0073] (3) Pour the liquid in Reactor B into Reactor A and keep stirring for 2 hours to make a modified gelatin compound solution for later use.

[0074] 2. Preparation of the second layer of membrane material (ultrafine activated humic acid powder), taking 100 kg per production as an example:

[0075] Mix 99 kg of pre-crushed 200-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com