Vacuum foamed material preparation method

A foam material and vacuum technology, which is applied in the field of vacuum foam material preparation, can solve the problems of cumbersome procedures, inability to realize wall thickness and vacuum hole control, and inability to realize precise control of foam wall thickness and size of foam hole vacuum state, etc., to achieve processing Convenient, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

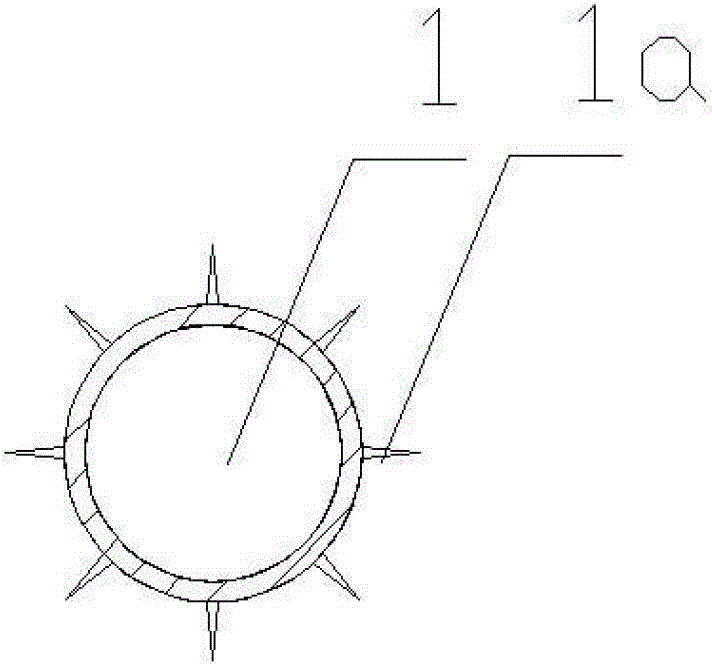

[0017] 1. Preparation of support body: select copper (melting point 1083° C.) to prepare spherical support body 1 (such as figure 1 shown), the outer surface of the spherical support body 1 is provided with flying spurs 1a, and the spherical support body 1 is vacuumed;

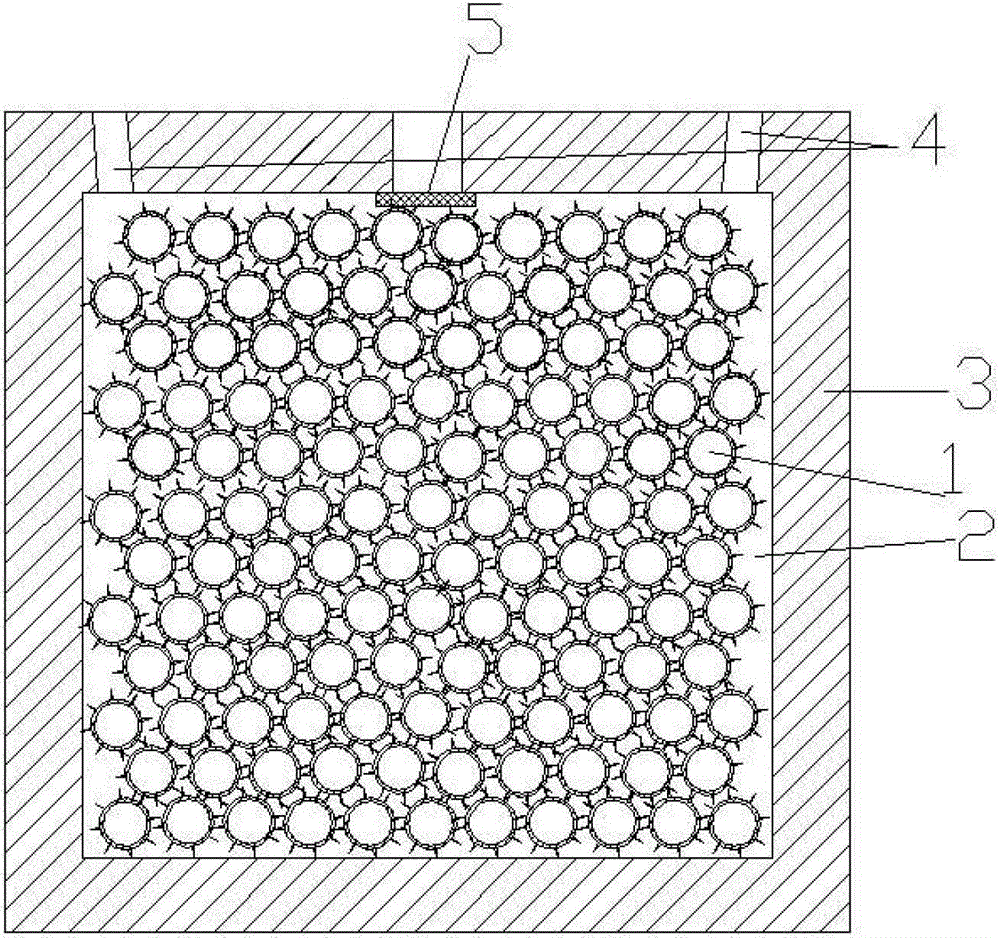

[0018] 2. If figure 2 As shown, the spherical support body 1 is poured into the mold 3, shaken and shaken, so that the spherical support body 1 is freely stacked in the mold 3, and the inner space of the mold 3 is filled, and the mold opening is blocked with a screen 5;

[0019] 3. Cast the aluminum foam material base material into the mold 3 to obtain the foam material base material 2. The casting temperature is 650-700° C., open the mold, perform heat treatment, and grind and polish, and finally obtain the vacuum foam material.

Embodiment 2

[0021] 1. Preparation of the support body: select steel (melting point above 1500°C) to prepare a capsule-shaped support body, the outer surface of the capsule-shaped support body is provided with flying spines, and vacuumize the capsule-shaped support body;

[0022] 2. Pour the capsule-shaped support into the mold, shake and shake well, so that the capsule-shaped support can be stacked freely in the mold, filling the inner space of the mold, and blocking the mold opening with a screen;

[0023] 3. Cast the foam material matrix material aluminum into the mold 3 to obtain the foam material matrix. The casting temperature is 650-700° C., open the mold, perform heat treatment, and grind and polish, and finally obtain the vacuum foam material.

Embodiment 3

[0025] 1. Preparation of the support body: select aluminum (melting point 660°C) or magnesium (melting point 649°C) to prepare a regular tetrahedral support body, the outer surface of the regular tetrahedron support body is provided with flying spurs, and the regular tetrahedron support body is drawn into vacuum;

[0026] 2. Pour the tetrahedral support into the mold, oscillate and shake evenly, so that the tetrahedral support can be stacked freely in the mold, filling the inner space of the mold, and blocking the mold opening with a screen;

[0027] 3. Cast the bisphenol A type epoxy resin as the foam material base material into the mold 3 to obtain the foam material base material. The casting temperature is 58-93° C., open the mold, perform heat treatment, and polish to obtain the vacuum foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com