Method for producing p-methylacetophenone with fixed-bed reactor

A fixed-bed reactor, the technology of p-methylacetophenone, which is applied in the fields of food and chemical industry, can solve the problems such as catalyst can not be recycled, equipment is corroded after treatment, large reaction investment consumption, etc., and achieves easy scale and continuous production. , The effect of low design cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

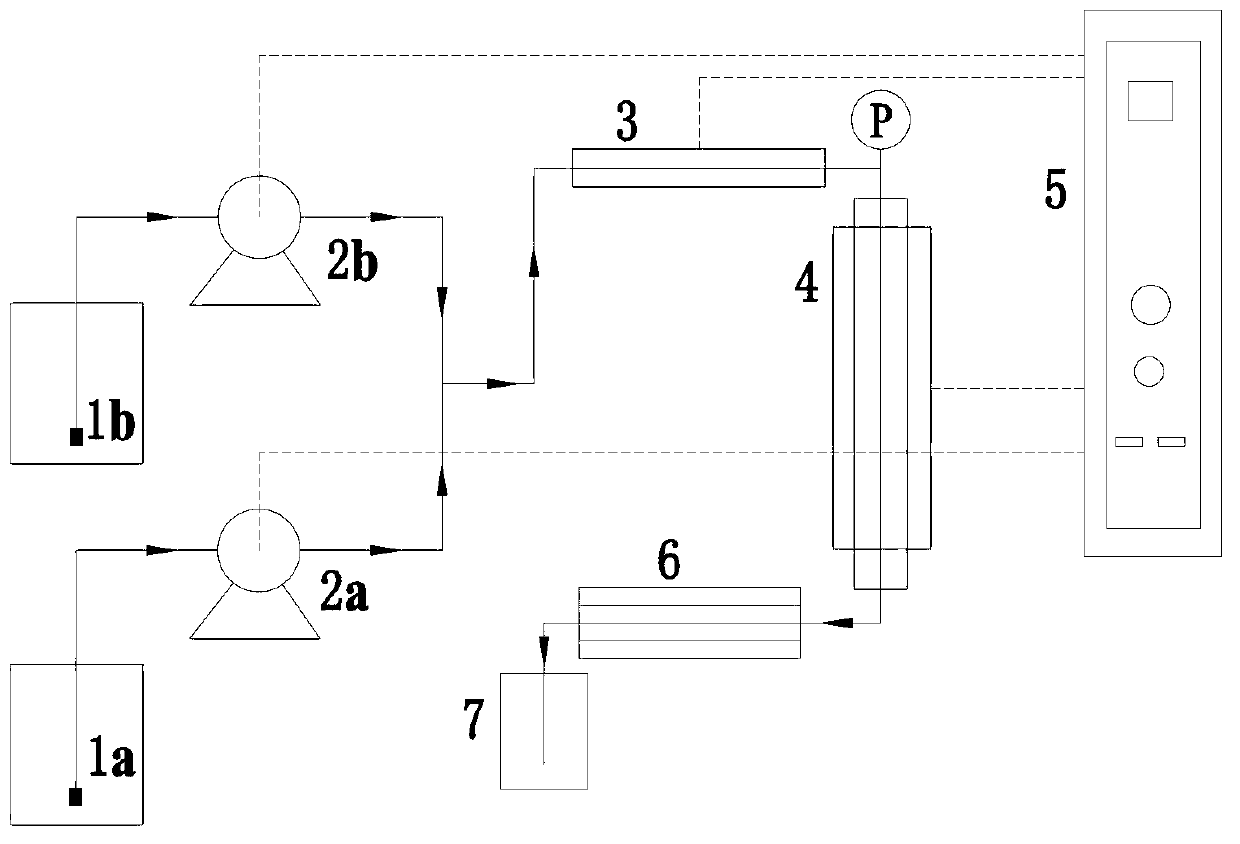

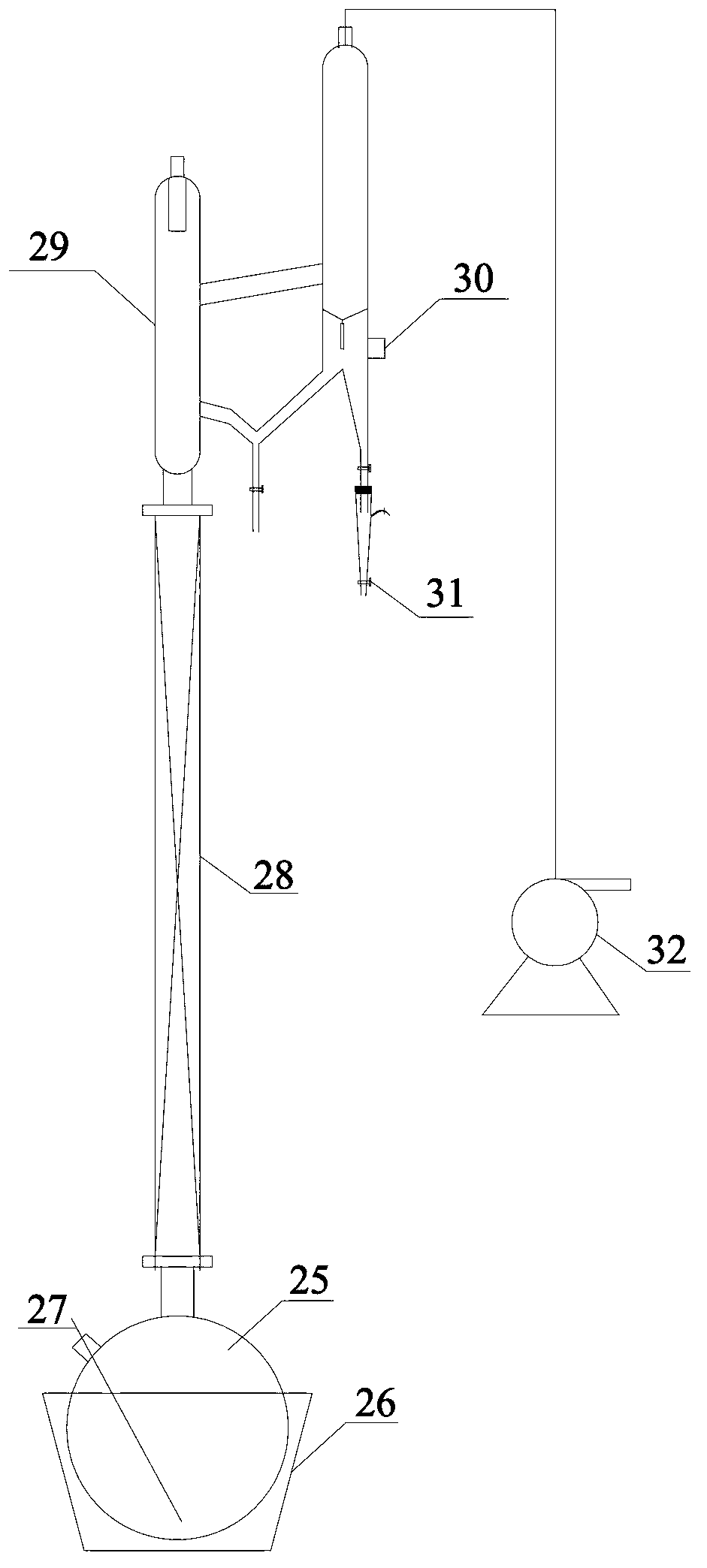

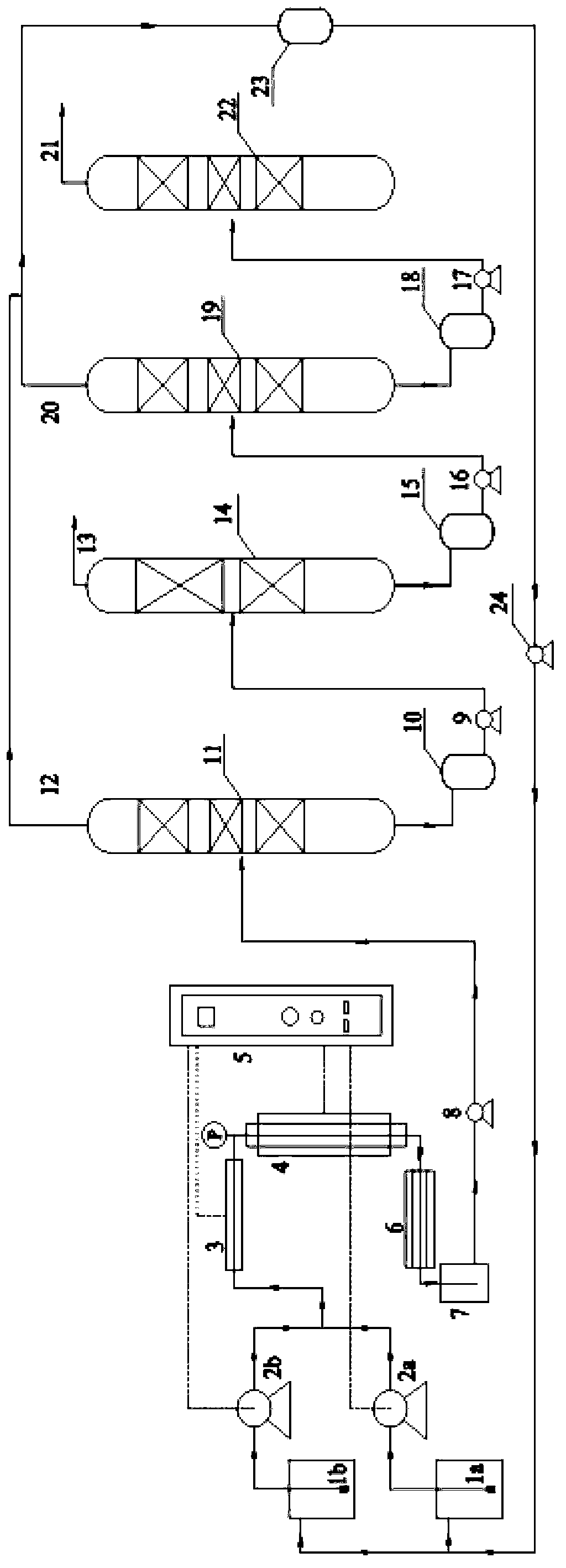

Method used

Image

Examples

Embodiment 1

[0034] Reaction section: MCM-41 catalyst bed is installed in the fixed bed reactor, and the catalyst bed packing method is random; at the temperature of 60°C and the pressure of 0.05MPa, the molar ratio of 1:0.1 Toluene and acetic anhydride are pre-mixed uniformly, and are sent into a fixed-bed reactor with a raw material feeding pump to carry out acylation reaction to obtain p-methylacetophenone crude product, the conversion rate of acetic anhydride is 35.7%, and the yield of p-methylacetophenone 95%;

[0035] Refining section: The crude product of p-methylacetophenone is purified by batch distillation to obtain p-methylacetophenone product with a purity of 99%.

Embodiment 2

[0037] Reaction section: HZSM-5 catalyst bed is installed in the fixed bed reactor, and the catalyst bed packing method is random; at the temperature of 80°C and the pressure of 0.3MPa, the molar ratio of 1:2 Toluene and acetyl chloride are pre-mixed uniformly, and are sent into a fixed-bed reactor with a raw material feed pump to carry out acylation reaction to obtain the crude product of p-methylacetophenone, the conversion rate of toluene is 52%, and the yield of p-methylacetophenone is 96%;

[0038] Refining section: The crude p-methylacetophenone is purified by batch distillation to obtain p-methylacetophenone product with a purity of 99.5%.

Embodiment 3

[0040] Reaction section: The fixed bed reactor is equipped with a Mont-K10 catalyst bed, and the catalyst bed is packed in random type; under the conditions of temperature 160 ° C and pressure 0.5 MPa, the molar ratio of 1:15 Toluene and acetic acid are sent into the fixed-bed reactor respectively with raw material feeding pump and carry out acylation reaction to obtain p-methylacetophenone crude product, the conversion rate of toluene is 65%, and the yield of p-methylacetophenone is 96%;

[0041] Refining section: The crude p-methylacetophenone is purified by batch distillation to obtain p-methylacetophenone product with a purity of 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com