Octenyl succinic acid cannaedulisker starch ester and preparation method thereof

A technology of octenyl succinic acid and octenyl succinic anhydride, which is applied in the field of octenyl succinic acid starch ester and its preparation, can solve problems such as no research on octenyl succinic acid canna starch ester, and achieve good freezing and thawing Stability and retrogradation stability, high product quality and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

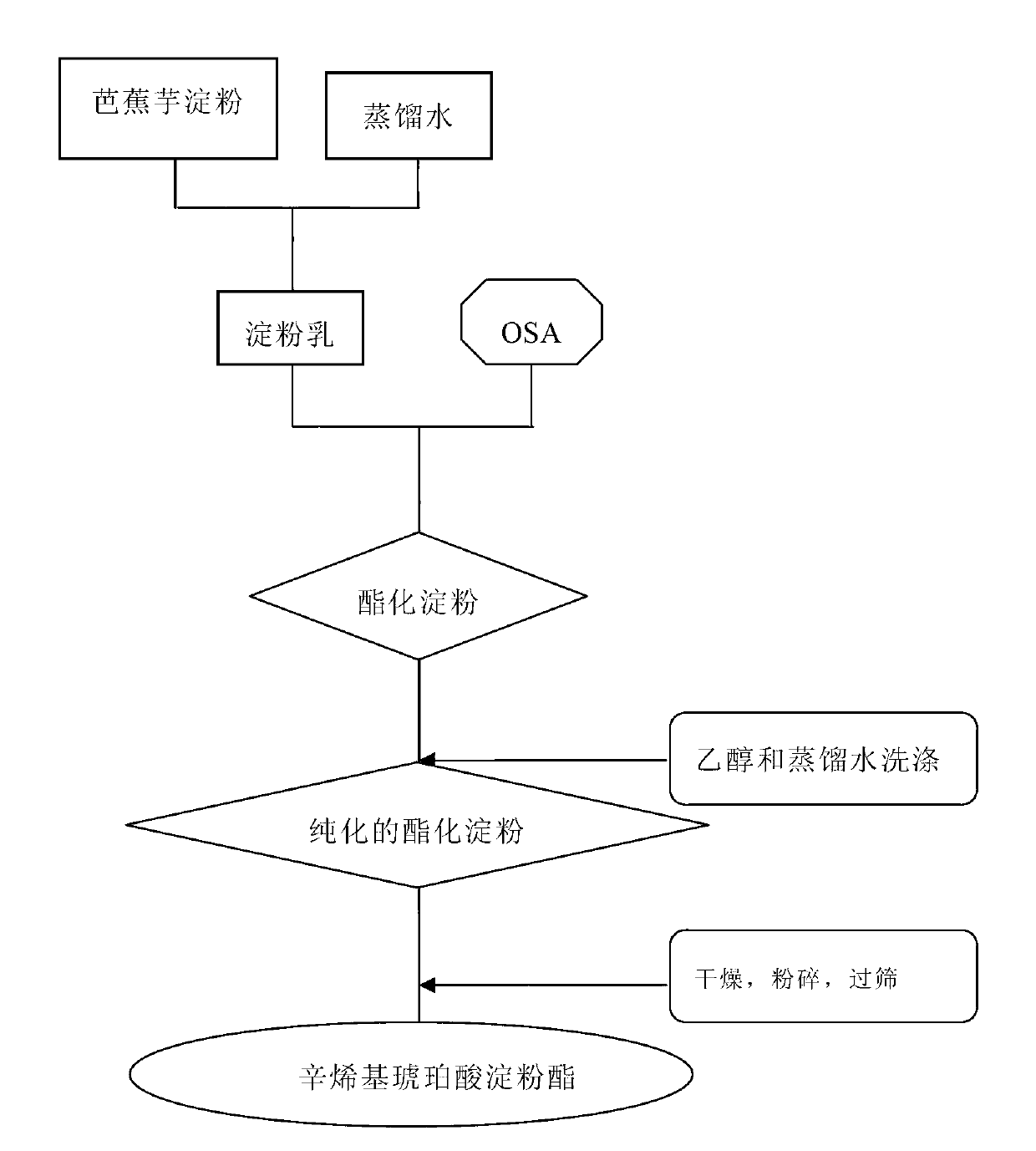

[0030] In the reactor, 40g of canna starch was dissolved in 100mL of distilled water to prepare canna starch milk with a concentration of 40% (w / v, on a dry basis), and the pH of the starch milk was adjusted with 3% NaOH solution. Turn it up to 9.

[0031] At a reaction temperature of 40° C., 1.2 g of OSA (diluted in 5 times the volume of absolute ethanol) was evenly added within 1 hour. In order to prevent alcoholysis of OSA, it must be prepared on site. At the same time, use 3% (W / V) NaOH solution to control the pH value of the system and keep it stable at around 9.

[0032] After continuing the reaction for 1.5h, adjust the pH value to 6.5 with 3% (W / V) HCl solution, wash twice with 75% (V / V) ethanol and distilled water, dry in an oven at 40°C after dehydration, and grind through 100 mesh Sieve to obtain octenyl succinic acid canna starch ester, and seal the bag for storage. The degree of substitution of canna starch octenyl succinate was determined to be 0.01018 by pickl...

Embodiment 2

[0037] In the reactor, dissolve 30g of canna starch in 100mL of distilled water to prepare starch milk with a concentration of 30% (w / v, based on dry basis weight), and use 3% (W / V) NaOH solution to dissolve the starch The pH of the milk was adjusted to 9.

[0038] At a reaction temperature of 30° C., 0.9 g of OSA (diluted in 5 times the volume of absolute ethanol) was evenly added within 1 hour. In order to prevent alcoholysis of OSA, it must be prepared on site. At the same time, use 3% (W / V) NaOH solution to control the pH value of the system and keep it stable at around 9.

[0039] After continuing to react for 3.5 hours, adjust the pH value to 7.0 with 3% (W / V) HCl solution, wash twice with 75% (V / V) ethanol and distilled water, dry in a 40°C oven after dehydration, and grind through 100 mesh Sieve to obtain octenyl succinic acid canna starch ester, and seal the bag for storage. The degree of substitution of canna starch octenyl succinate was determined to be 0.00919 by...

Embodiment 3

[0041] In the reactor, 35g of canna starch was dissolved in 100mL of distilled water to prepare starch milk with a concentration of 35% (w / v, on a dry basis), and the starch milk was mixed with 3% (W / V) NaOH solution. The pH of the milk was adjusted to 8.5.

[0042] At a reaction temperature of 35° C., slowly add 1.05 g of OSA (dilute it in 5 times the volume of absolute ethanol) within 1 hour. In order to prevent alcoholysis of OSA, it must be prepared on site. At the same time, use 3% (W / V) NaOH solution to control the pH value of the system and keep it stable at about 8.5.

[0043] After continuing to react for 2.5 hours, adjust the pH value to 6.8 with 3% (W / V) HCl solution, wash twice with 75% (V / V) ethanol and distilled water, and dehydrate to obtain octenyl succinic acid plantain Taro starch ester, sealed bag preservation. The degree of substitution of canna starch octenyl succinate was determined to be 0.01118 by pickling method. The resistant starch content of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com