Polypropylene/polylactic acid/starch composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of plastic materials, can solve problems such as unfavorable preparation of PLA/starch composite materials, unsatisfactory mechanical properties, and decreased mechanical properties, and achieves improved interface compatibility, good mechanical properties, and improved The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

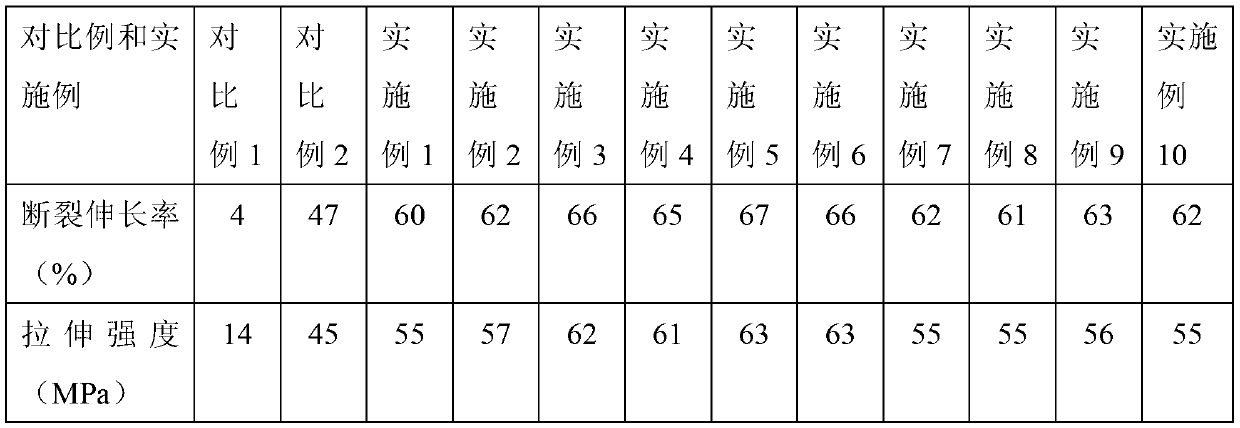

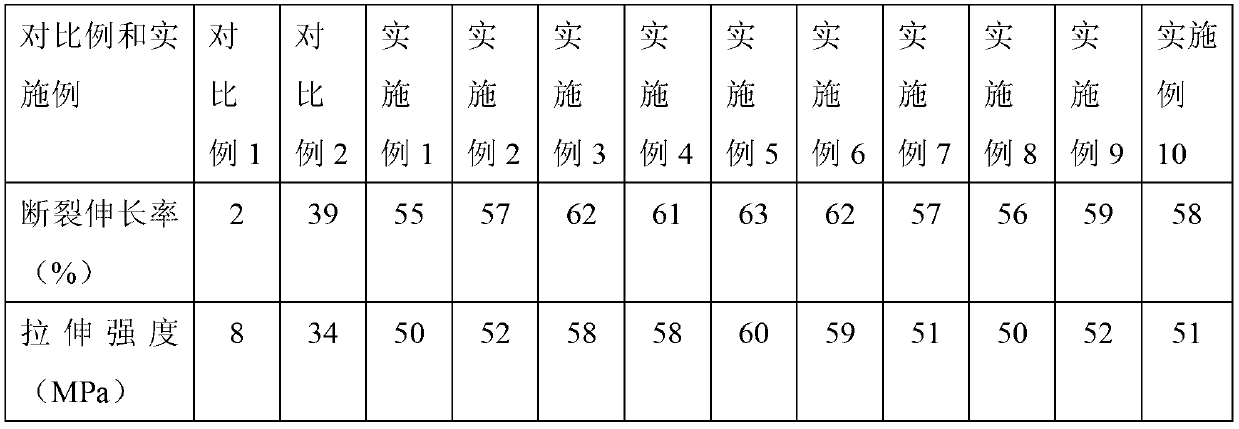

Examples

Embodiment 1

[0045] Weigh the following raw materials in parts by weight:

[0046] 100 parts by weight of dried cornstarch (4.1% by weight of moisture, Zhucheng Xingmao Corn Development Co., Ltd.), 3 parts by weight of hexamethylene diisocyanate (Chinese medicine reagent), 173 parts by weight of toluene (Chinese medicine reagent) , dibutyltin dilaurate (Sinopharm Reagent) 0.5 parts by weight, polypropylene (polypropylene random copolymer resin, R724J, GS-Caltex Corporation) 20 parts by weight, polylactic acid (Natureworks4032D, LD mixed polylactic acid) 45 parts by weight , 5 parts by weight of castor oil polyol (Aladdin reagent), 2.5 parts by weight of ethylene-octene copolymer resin (Aldrich Chemical Company) grafted by anhydrous maleic anhydride, polylactic acid grafted by anhydrous maleic anhydride Resin (Aldrich Chemical Company) 2.5 parts by weight.

[0047] The preparation method of polypropylene / polylactic acid / starch composite material is as follows:

[0048] 1) Add 100 parts by...

Embodiment 2

[0053] Weigh the following raw materials in parts by weight:

[0054] 100 parts by weight of dried cornstarch (4.1% by weight of moisture, Zhucheng Xingmao Corn Development Co., Ltd.), 5 parts by weight of hexamethylene diisocyanate (Chinese medicine reagent), 173 parts by weight of toluene (Chinese medicine reagent) , dibutyltin dilaurate (Sinopharm Reagent) 0.5 parts by weight, polypropylene (polypropylene random copolymer resin, R724J, GS-Caltex Corporation) 20 parts by weight, polylactic acid (Natureworks4032D, LD mixed polylactic acid) 45 parts by weight , 5 parts by weight of castor oil polyol (Aladdin reagent), 2.5 parts by weight of ethylene-octene copolymer resin (Aldrich Chemical Company) grafted by anhydrous maleic anhydride, polylactic acid grafted by anhydrous maleic anhydride Resin (Aldrich Chemical Company) 2.5 parts by weight.

[0055] The preparation method of polypropylene / polylactic acid / starch composite material is as follows:

[0056] 1) Add 100 parts by...

Embodiment 3

[0061] Weigh the following raw materials in parts by weight:

[0062] 100 parts by weight of dried cornstarch (4.1% by weight of moisture, Zhucheng Xingmao Corn Development Co., Ltd.), 7 parts by weight of hexamethylene diisocyanate (Chinese medicine reagent), 173 parts by weight of toluene (Chinese medicine reagent) , dibutyltin dilaurate (Sinopharm Reagent) 0.5 parts by weight, polypropylene (polypropylene random copolymer resin, R724J, GS-Caltex Corporation) 20 parts by weight, polylactic acid (Natureworks4032D, LD mixed polylactic acid) 45 parts by weight , 5 parts by weight of castor oil polyol (Aladdin reagent), 2.5 parts by weight of ethylene-octene copolymer resin (Aldrich Chemical Company) grafted by anhydrous maleic anhydride, polylactic acid grafted by anhydrous maleic anhydride Resin (Aldrich Chemical Company) 2.5 parts by weight.

[0063] The preparation method of polypropylene / polylactic acid / starch composite material is as follows:

[0064] 1) Add 100 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com