Preparation process for extracting high-purity rare earth oxides from waste rare earth luminescent materials

A technology of rare earth oxides and rare earth hydroxides, which is applied in the direction of improving process efficiency, can solve problems such as emissions, waste of valuable resources, and environmental pollution, and achieve excellent product quality, which is conducive to resource utilization and environmental protection. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further elaborated below.

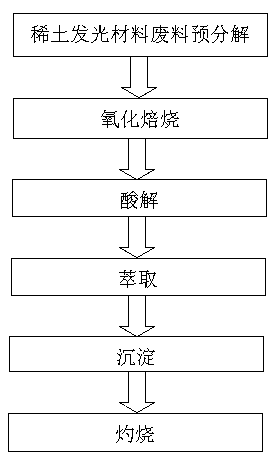

[0020] Such as figure 1 As shown, a preparation process for extracting high-purity rare earth oxides from waste rare earth luminescent materials includes the following six steps:

[0021] (1) Pre-decomposition of rare earth luminescent material waste; take 432g of rare earth luminescent material waste and add 1L of water to the container and stir to make a slurry, then heat to 60°C; add glacial acetic acid to the container and stir to remove impurities, and discharge after clarification Clear liquid; then add tap water for secondary impurity removal, after water washing is completed; add pure rare earth solution and stir again, add oxalic acid after 40 minutes at 60°C to precipitate part of the dissolved rare earth until it is detected that there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com