Biomass smoke-free combustion furnace

A technology of smokeless combustion and biomass, applied in combustion methods, combustion equipment, combustion of solid fuels, etc., can solve the problems of increasing ash residue, insufficiency, and small fuel porosity, and achieve full utilization, saving coal, Easy-to-build effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

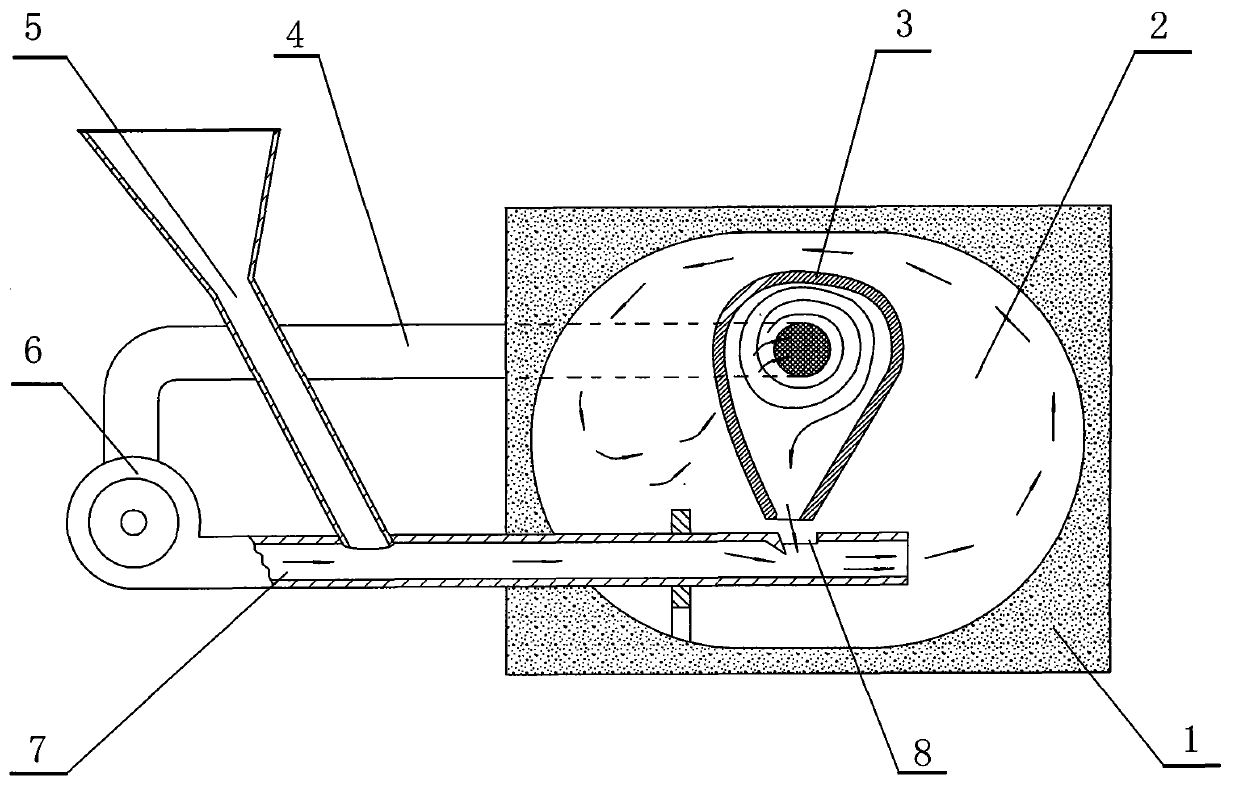

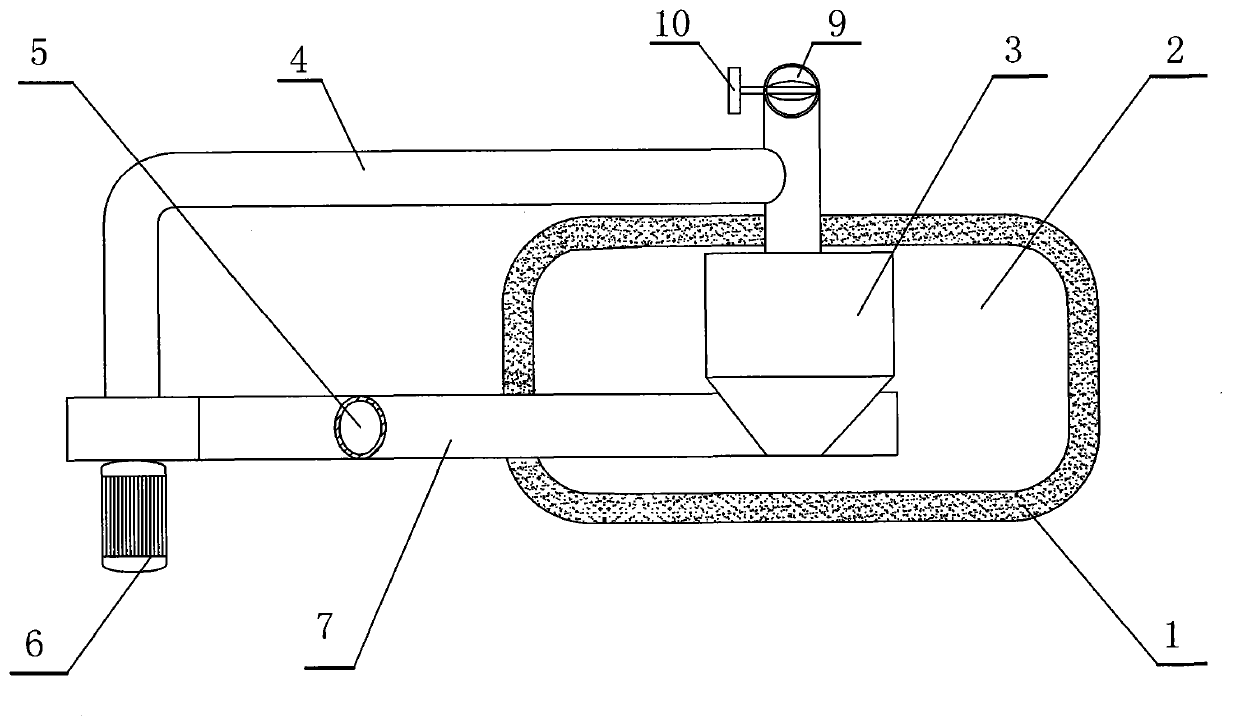

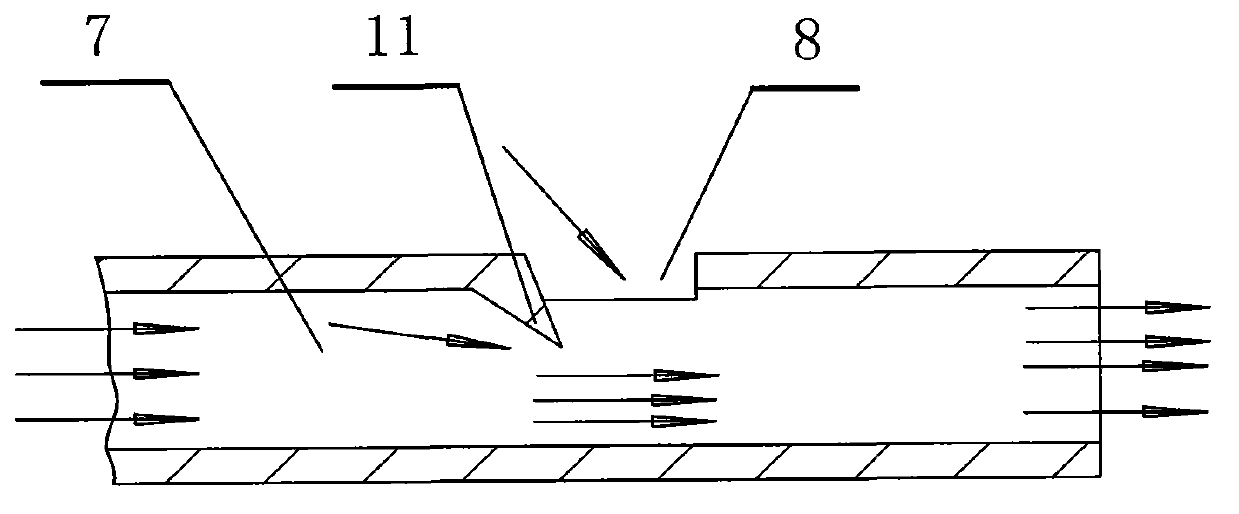

[0026] The first embodiment: as figure 1 , 2 As shown, the furnace body 1 of this biomass smokeless combustion furnace has a furnace 2 inside and a fan 6 outside, and the air supply pipe 7 of the fan 6 enters the furnace 2 and can deliver combustion-supporting air in the furnace 2 . The air supply pipe 7 is connected with a fuel delivery pipe 5 above a section of the body of heater 1 outside, and the fuel can enter the furnace 2 with the combustion-supporting air. As can be seen in the figure, the front and top of the air supply pipe 7 in the inner wall of the furnace 2 are circular arcs, and after the fuel enters the furnace 2, it can rotate up and down along the arc surface. There is a negative pressure port 8 on the front upper side of the air supply pipe 7, combined with image 3 It can be seen that the front edge of the negative pressure port 8, that is, the side where the combustion-supporting air passes first, is provided with a piece of air-pressing piece 11 bent obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com