Method for accurately determining calcium-based desulfurization agent main component

A technology for accurate determination and desulfurization agent, applied in the field of analytical chemistry and physical analysis, can solve the problem that only the total calcium content can be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

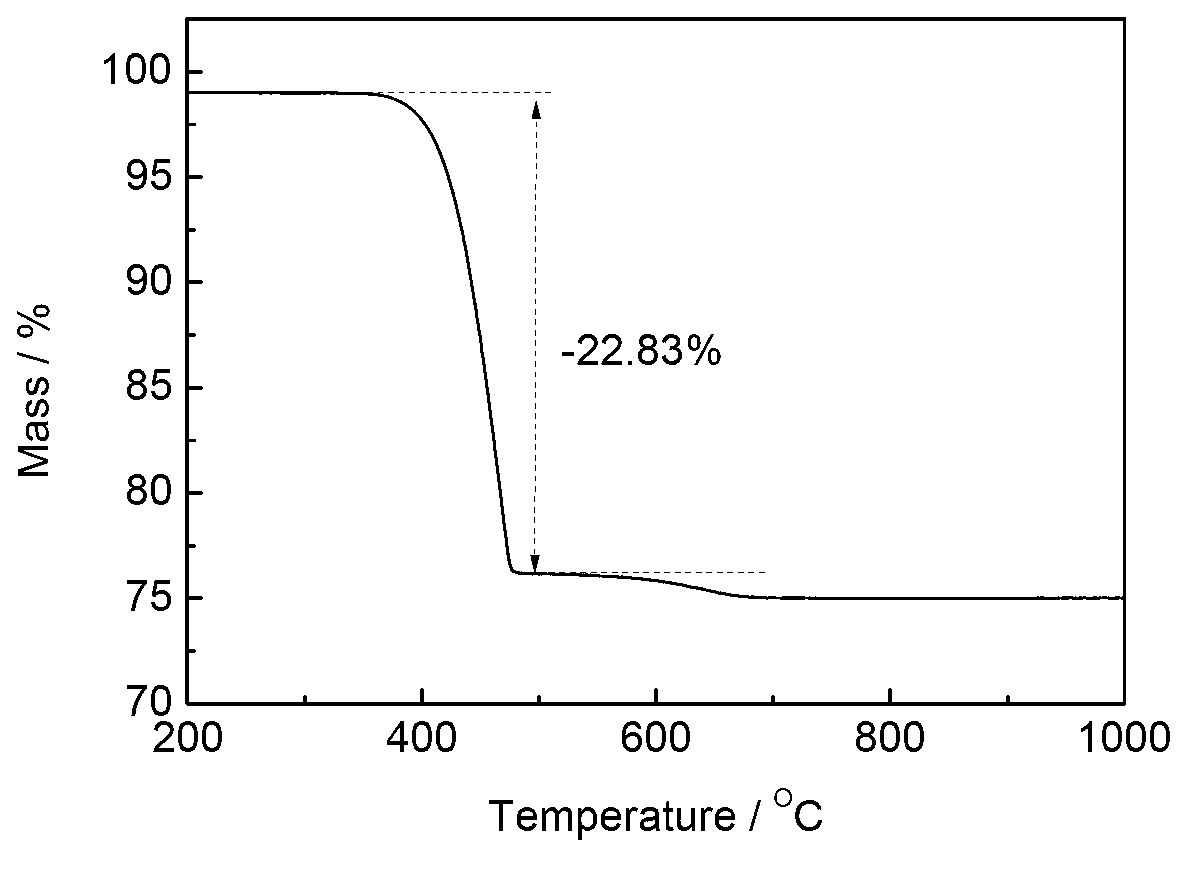

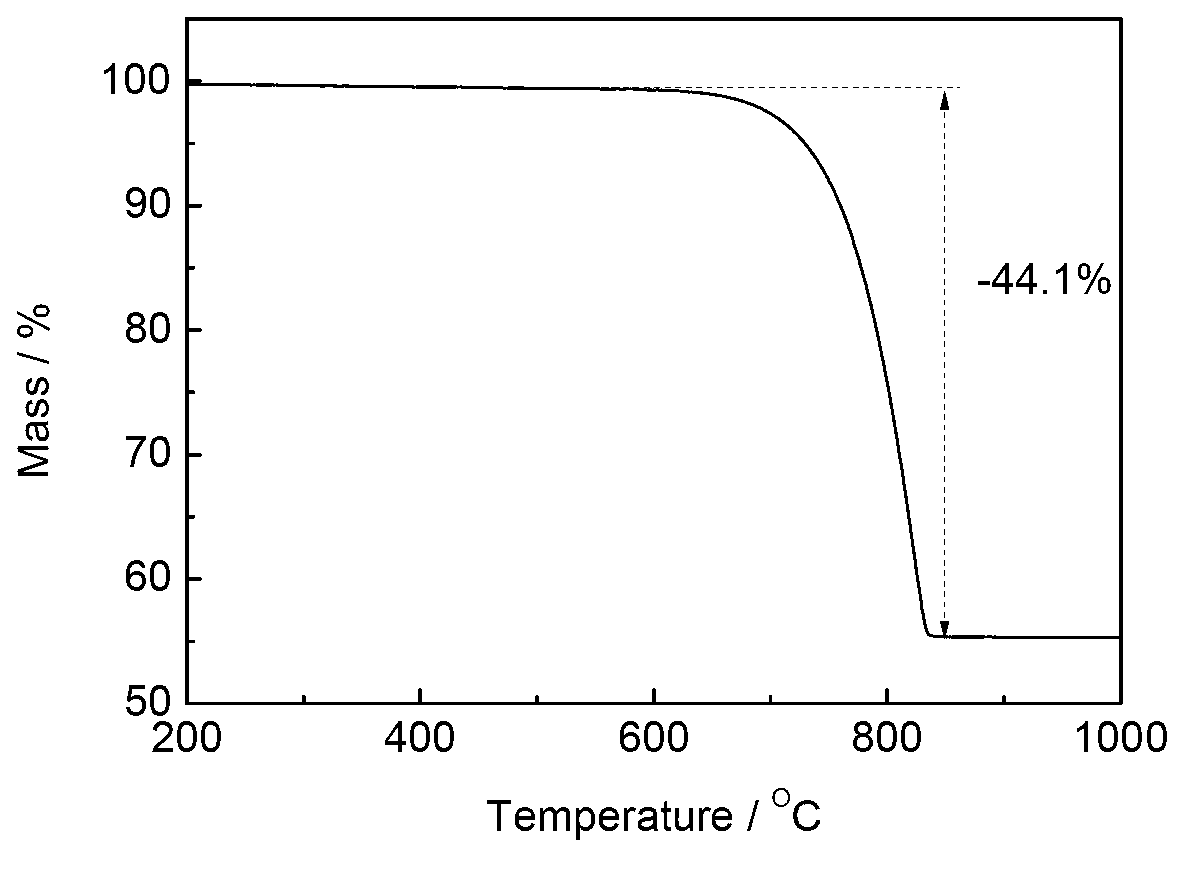

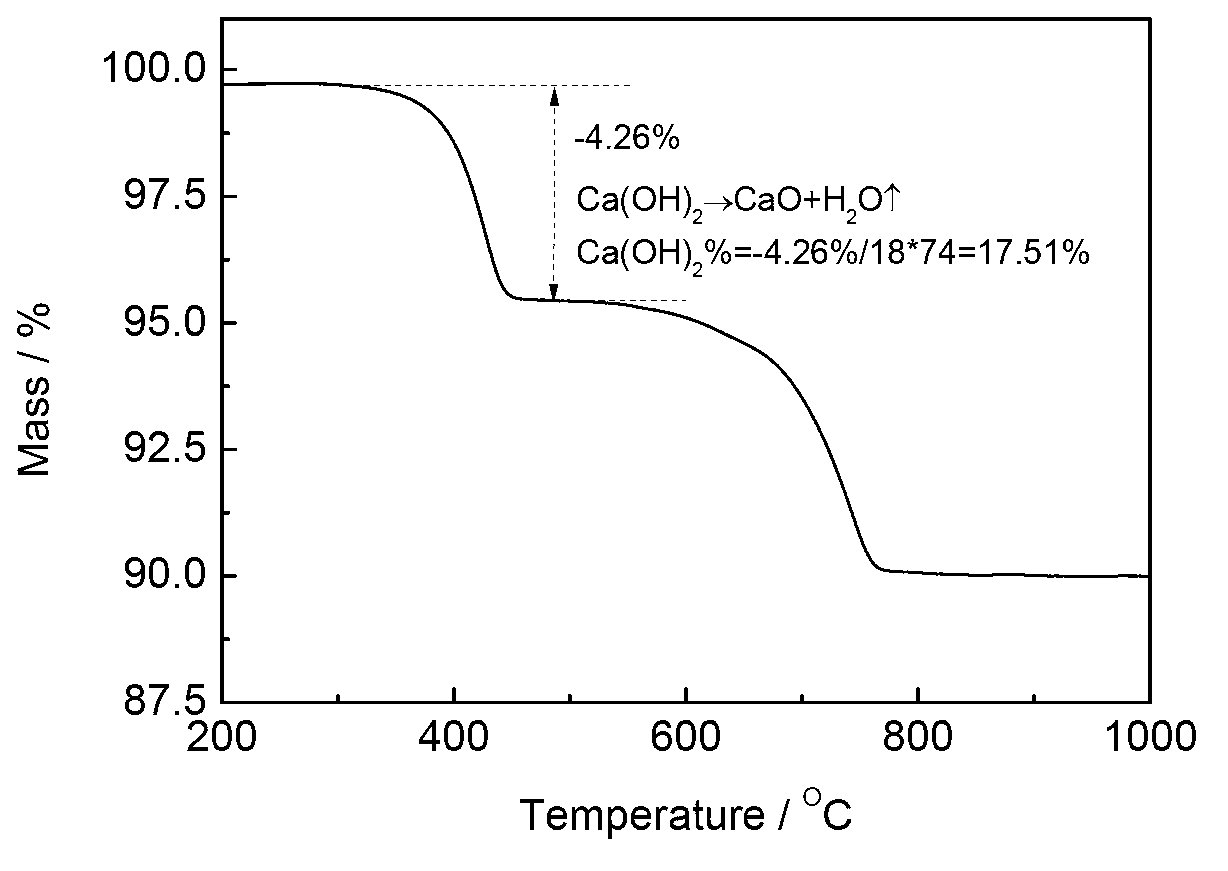

Embodiment 1

[0070] Weigh 0.1g~1.0g, preferably 0.5000g (accurate to 0.0001g), which has been prepared as a desulfurizer sample with a particle size of less than 0.15mm and placed in a closed container. Perform a blank test with the sample and place it in 100mL~ In a 500mL dry volumetric flask with stopper, preferably a 250mL Erlenmeyer flask, add 20-100mL of sucrose solution with a concentration of 100g / L to 300g / L. The amount of sample corresponds to the amount of sucrose solution. When it is small, relatively small or low-concentration sucrose solution should be used to dissolve the sample, preferably 50mL 200g / L sucrose solution. If the sample is not completely decomposed, 10mL 200g / L sucrose solution can be added each time, or Choose other concentration of sucrose solution and amount to dissolve the sample, stoppered and shake until the sample is completely decomposed, filter with quantitative filter paper in a volumetric flask, wash several times to obtain filtrate (1) and sediment (1)...

Embodiment 2

[0103] Weigh 0.1g~1.0g, preferably 0.5000g, and have prepared a desulfurizer sample with a particle size of less than 0.15mm, placed in a closed container, and carry out a blank test with the sample, and place it in a dry capacity of 100mL~500mL with a plug In the bottle, the volumetric flask is preferably a 250mL conical flask, and 20-100mL of sucrose solution with a concentration of 100g / L to 300g / L is added. The amount of sample corresponds to the amount of sucrose solution. When the sample amount is small, a relatively small amount should be used Or dissolve the sample in a low-concentration sucrose solution, preferably 50mL of a sucrose solution with a concentration of 200g / L. If the sample is not completely decomposed, add 10mL of a 200g / L sucrose solution each time, or choose a sucrose solution with other concentrations Dissolve the sample with the amount and stopper, shake it until the sample is completely decomposed, filter it in a volumetric flask with quantitative fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com