Method for forming self-aligned metal silicide

A technology of metal silicide and metal silicide layer, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of poor electrical performance of metal silicide, and achieve the effect of high device quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

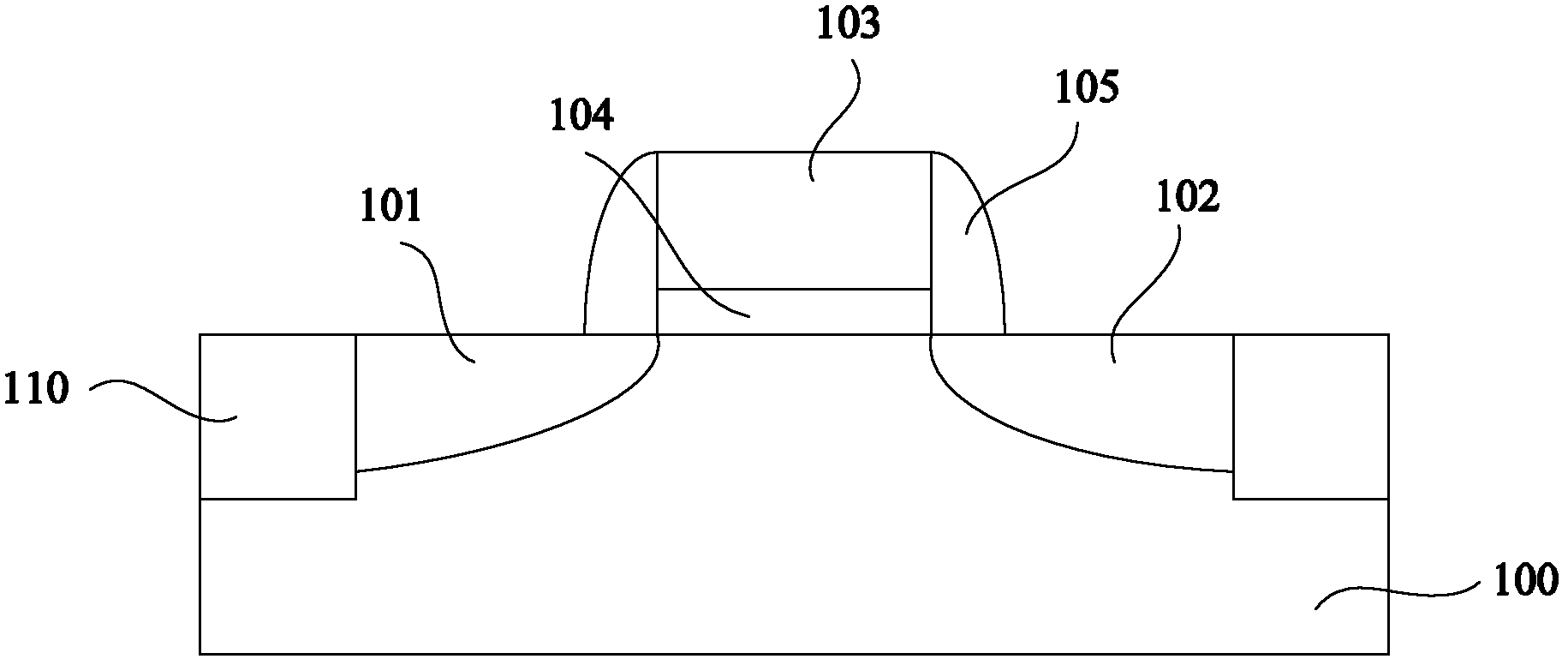

[0028] It can be seen from the background technology that the metal silicide formed by the prior art has poor electrical properties. Therefore, the inventors of the present invention have carried out in-depth research on the metal silicide formation method of the prior art, and found that: the existing nickel metal layer is directly used React with silicon to form a metal silicide layer. The metal elements in the metal silicide layer are unstable, and the metal elements are easy to diffuse into the substrate, which disrupts the lattice structure of silicon atoms in the source and drain regions, which is even worse. Ground, metal elements will diffuse to the bottom of the channel, causing leakage current at the source, drain, and substrate contacts.

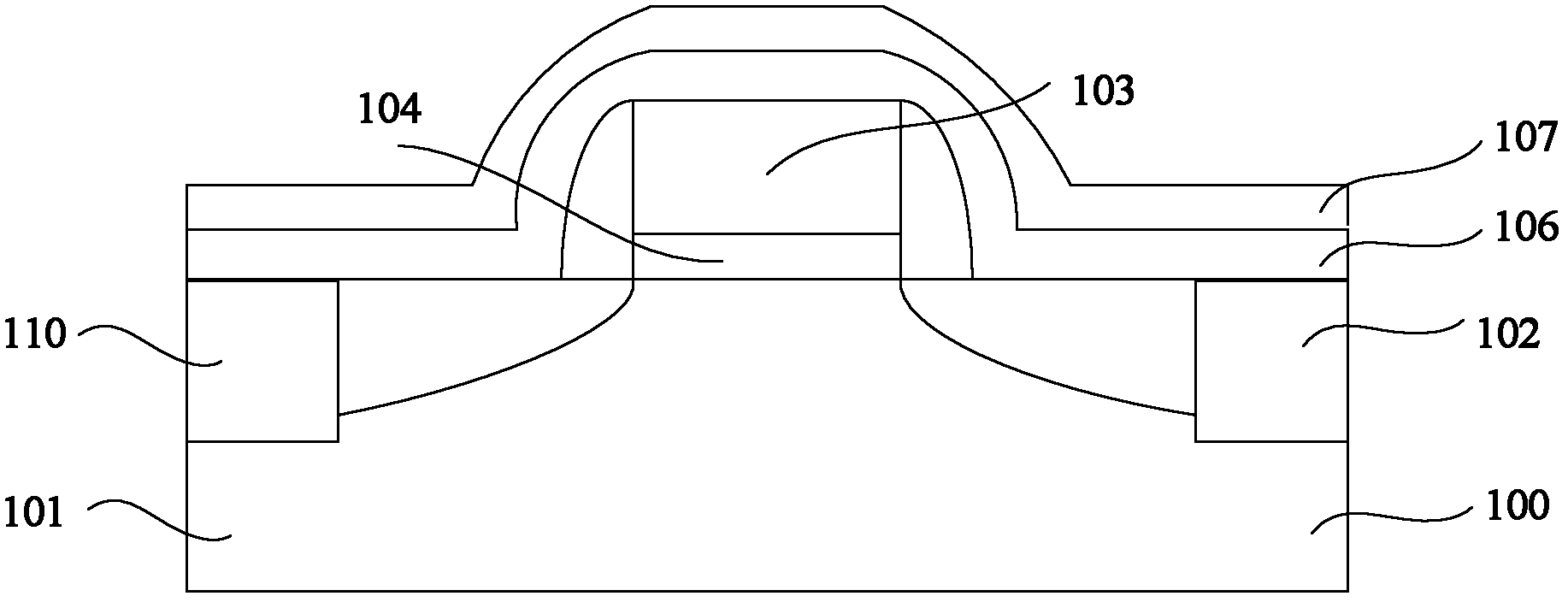

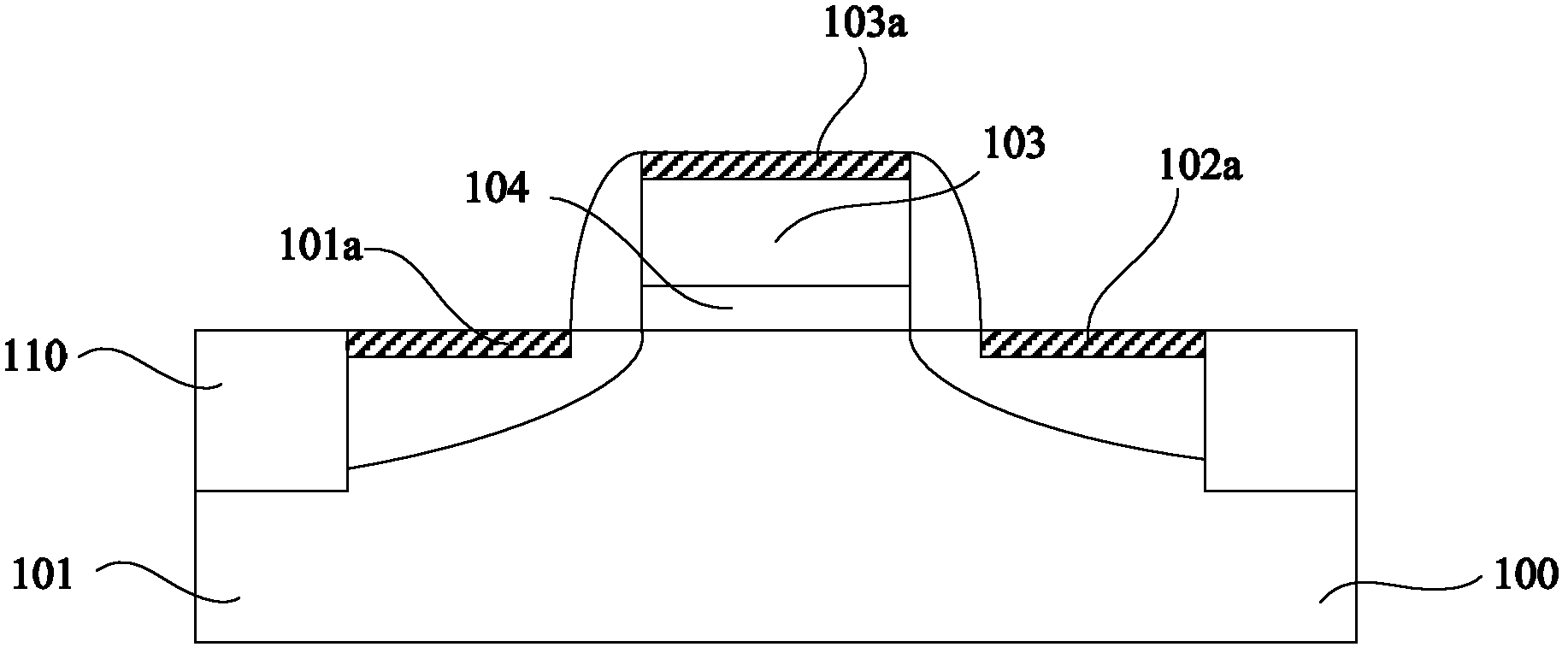

[0029] In view of the above-mentioned defects, the inventor conducted further research and found that: a nickel-platinum alloy target is sputtered by a physical vapor deposition process, thereby forming a nickel-platinum alloy meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com