Oil-in-water emulsifiable paste and preparation method for same

A technology of oil-in-water emulsion and mineral oil, which is applied in the field of cream and can solve the problems of high temperature resistance of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

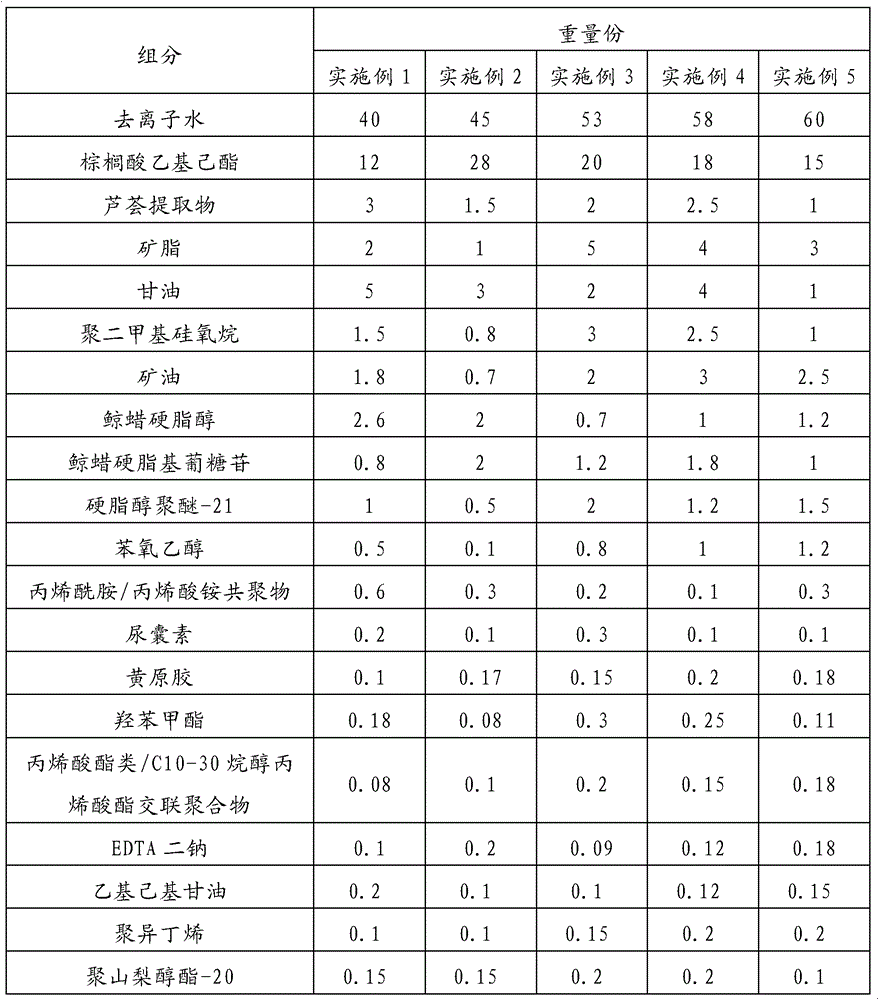

Embodiment 1-5

[0019]

preparation Embodiment 1-5

[0021] The oil-in-water cream provided by the invention is prepared through the following steps:

[0022] A. Add quantitative deionized water, disodium EDTA, acrylates / C10-30 alkanol acrylate crosslinked polymer and xanthan gum dispersed with glycerin into the water pot, and heat to 70-75°C, Add allantoin and methylparaben afterwards, after dissolving completely, the aqueous phase material is prepared for use;

[0023] B. Add quantitative petrolatum, polydimethylsiloxane, mineral oil, cetearyl alcohol, ethylhexyl palmitate, cetearyl glucoside and stearyl ether-21 to the oil In the pot, heat to 70-75°C and melt completely to obtain the oil phase material for use;

[0024] C. Vacuumize the emulsification pot after preheating, use negative pressure to pump 2 / 3 of the water phase material into the emulsification pot, stir and homogenize, and then use negative pressure to pump the oil phase material into the emulsification pot, and finally pump Add the remaining water phase mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com