Method for preparing active carbon composite filter core

A composite filter element and activated carbon technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low strength of activated carbon, weak adsorption force, low product performance, etc. The effect of strong ability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

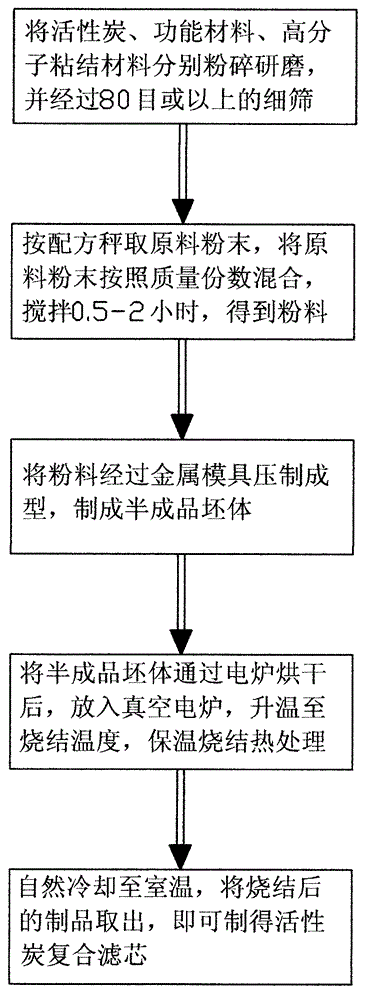

[0030] Example 1: See figure 1 , the present embodiment discloses a kind of preparation method of 10 cun standard cylindrical activated carbon composite filter elements, the raw materials and mass parts thereof used for the activated carbon composite filter element are: 90% of U.S. Calgon coconut shell charcoal powder produced in 200 mesh Sri Lanka, Iodine value 1200; 200 mesh food grade polyethylene (PE) 10%.

[0031] Preparation steps:

[0032] (1) Raw material pretreatment: Grind activated carbon and polyethylene separately, and pass through a 200-mesh sieve.

[0033] (2) Batching molding: Weigh the raw materials according to the above formula and mix them evenly. Put the mixed raw materials into the mixer according to the proportion of 1 part of the mixture (mass ratio), stir for 0.5-2 hours to obtain powder, add a small amount of pure water, The powder is semi-dry pressed into a cylindrical shape, and then dried after forming.

[0034] (3) Sintering: put the dried gree...

Embodiment 2

[0037] Example 2: See figure 1 , the present embodiment discloses a method of using activated carbon and nano-metal clusters as raw materials to prepare an activated carbon composite filter element. The raw materials and mass parts thereof used in the activated carbon composite filter element are: 400 mesh origin Sri Lanka, Calgon coconut shell activated carbon powder in the United States 80%, iodine value 1200; 400 mesh nano metal clusters 10%; 400 mesh food grade polyethylene (PE) 10%.

[0038] Preparation steps:

[0039] (1) Raw material pretreatment: grind the 3 kinds of materials respectively, and pass through a 400-mesh sieve.

[0040] (2) Batching molding: Weigh the raw materials according to the above formula and mix them evenly. Put the mixed raw materials into the mixer according to the proportion of 1 part of the mixture (mass ratio), stir for 0.5-2 hours to obtain powder, add a small amount of pure water, The powder is semi-dry pressed into a cylindrical shape, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com