Ongoing residue filter mingled with plastic hot-melt extrusion

A technology of hot-melt extrusion and slag filter, which is applied in the field of slag filter, can solve the problems of increased workload of staff, difficult removal of dead corners, control of slag discharge time, etc., to achieve the effect of solving time and labor costs, hot melting and energy saving Better, convenient manufacturing and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

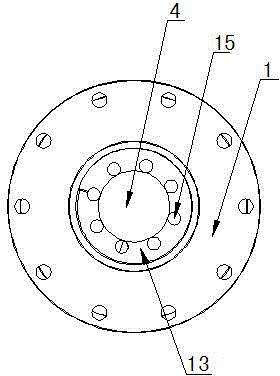

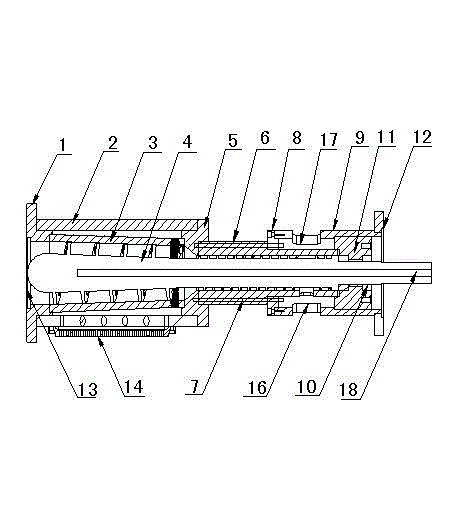

[0015] Please combine figure 1 , figure 2 As shown, the uninterrupted residue filter for hybrid plastic hot-melt extrusion of the present invention is mainly composed of two parts: a filter system and a slag discharge system, and the filter system and the slag discharge system are connected by a transition sleeve 6; the filter system mainly includes Feeding port connecting flange 1, connecting sleeve 2, conical filter sleeve 3, screw rod 4, transition sleeve connecting flange 5, feeding port 13, discharge port 14, both ends of connecting sleeve 2 and conical filter sleeve 3 They are respectively connected with the connecting flange 1 of the feed inlet and the connecting flange 5 of the transition sleeve, the discharge port 14 is arranged under the connecting sleeve 2, the conical filter sleeve 3 is arranged in the cavity of the connecting sleeve 2 with a heater, and the outer The diameter is smaller than the inner diameter of the connecting sleeve 2, and the conical filter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com