Patents

Literature

59results about How to "Solve time cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DRL-based multi-unmanned aerial vehicle aerial base station dynamic deployment method and system

ActiveCN112511250AIncrease coverageReal-time overlay implementationInternal combustion piston enginesTransmission monitoringNetwork generationSimulation

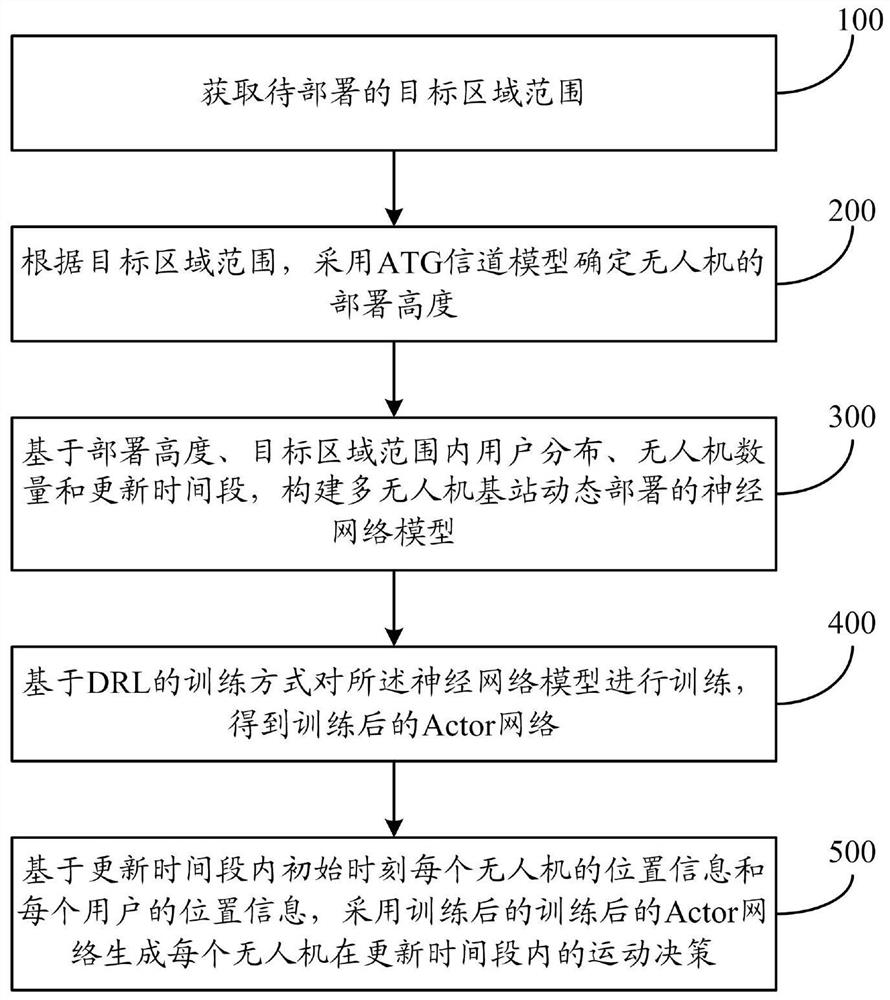

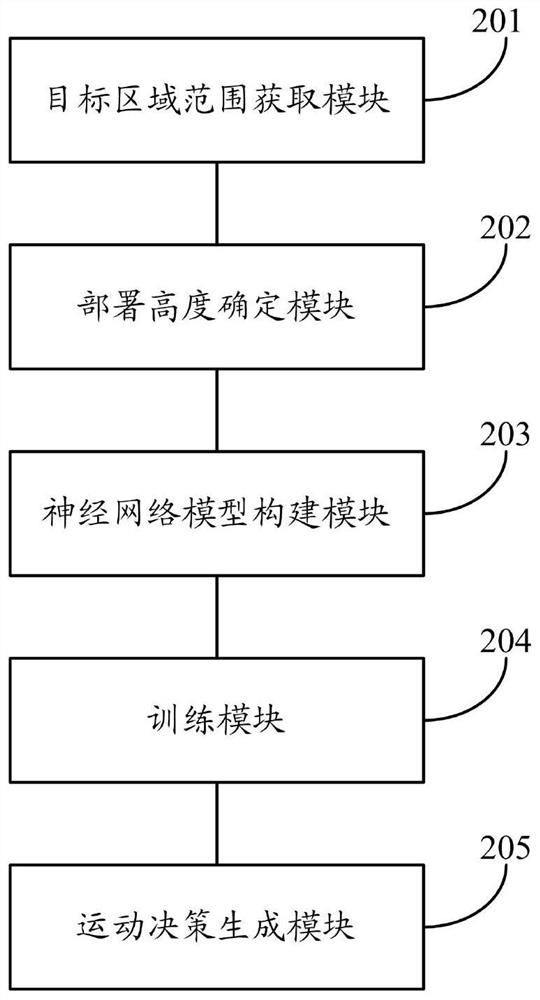

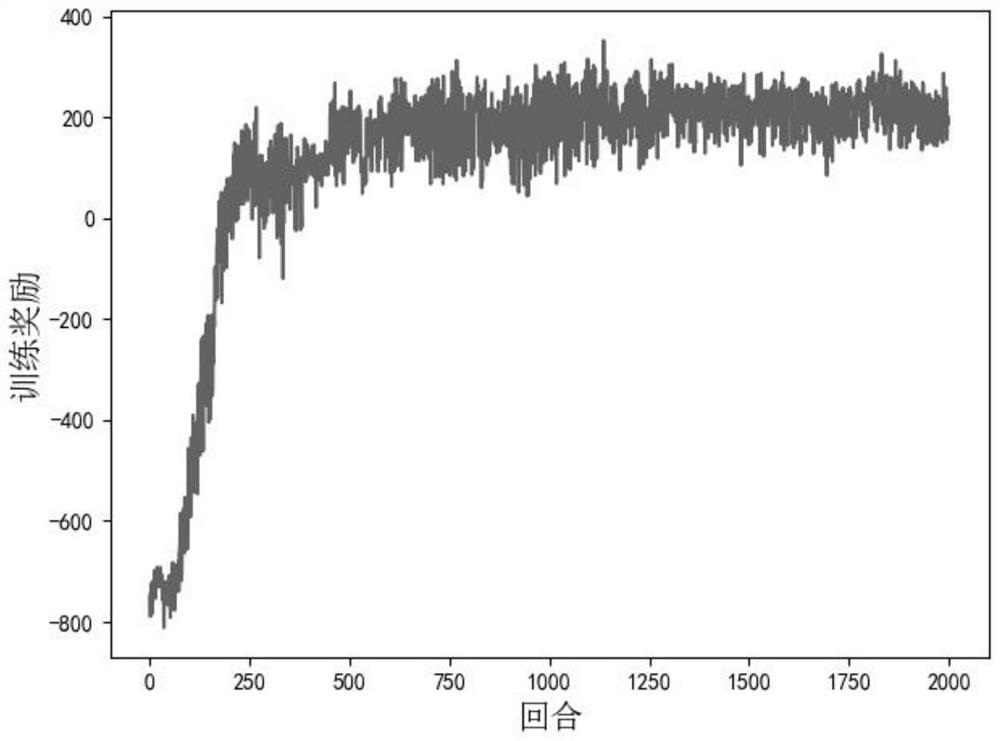

The invention relates to a DRL-based multi-unmanned aerial vehicle air base station dynamic deployment method and system. The method comprises the steps of obtaining a to-be-deployed target area range; determining the deployment height of the unmanned aerial vehicle by adopting an ATG channel model according to the target area range; based on the deployment height, the user distribution in the target area range, the number of the unmanned aerial vehicles and the update time period, constructing a neural network model of multi-unmanned aerial vehicle base station dynamic deployment, wherein theneural network model comprises an Actor network and a Critic network; training the neural network model based on a DRL training mode to obtain a trained Actor network; and based on the position information of each unmanned aerial vehicle and the position information of each user at the initial moment in the updating time period, generating a motion decision of each unmanned aerial vehicle in theupdating time period by adopting the trained Actor network. According to the invention, the communication efficiency of the unmanned aerial vehicle base station can be improved under the condition oftime-varying ground user position information.

Owner:中国人民解放军火箭军工程大学

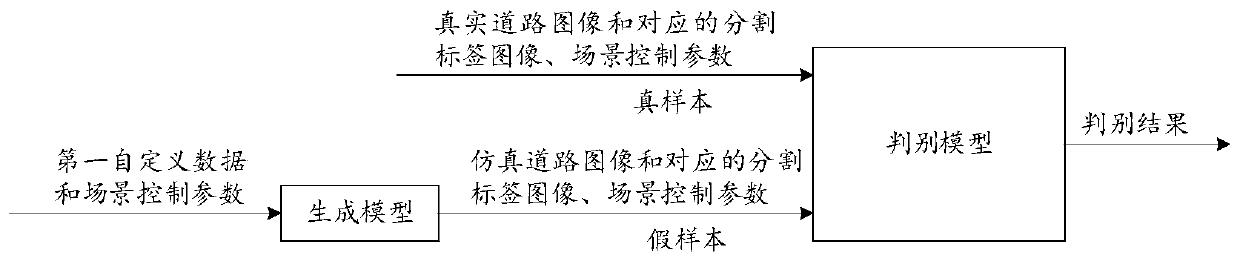

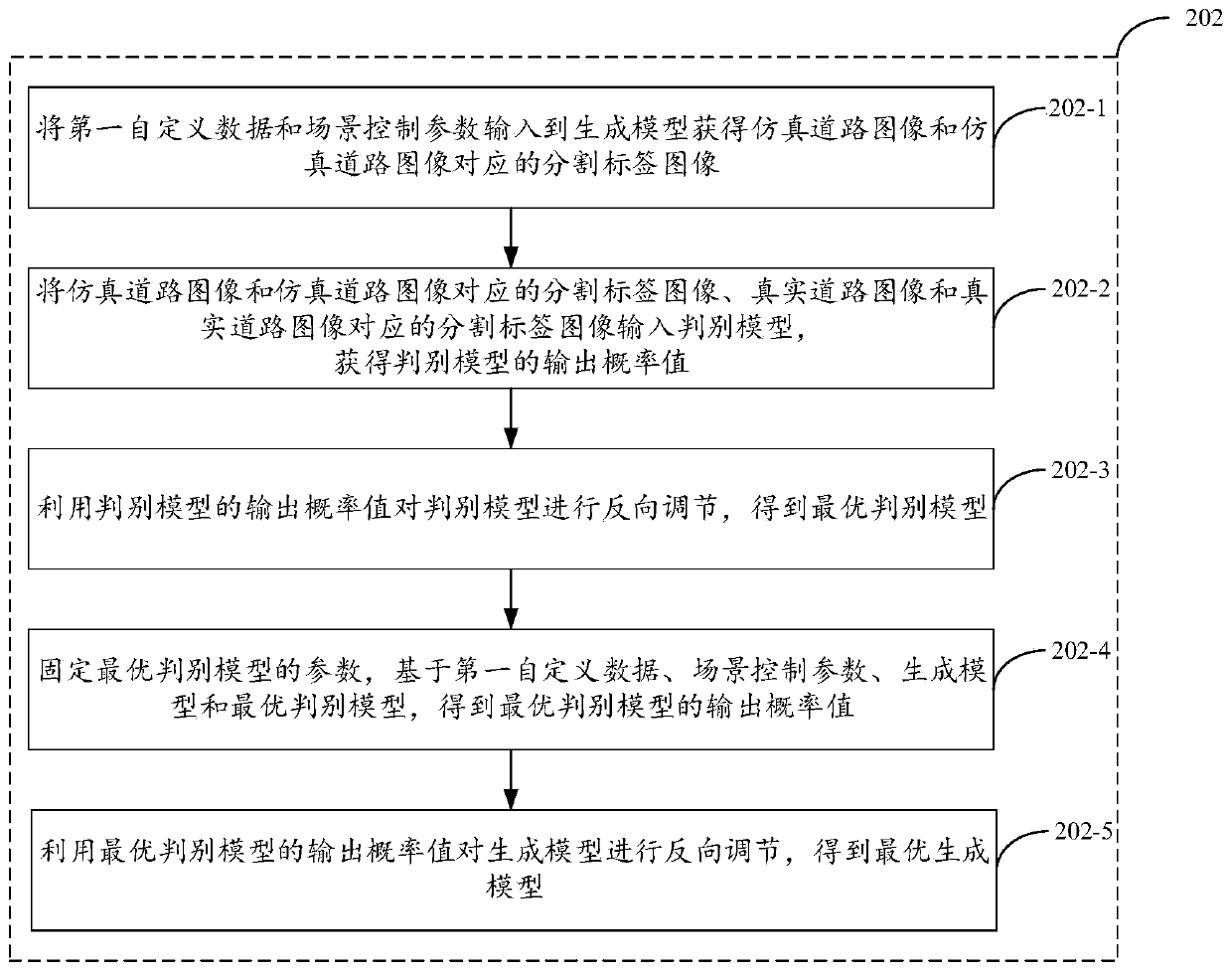

Road data generation method and device, electronic equipment and storage medium

ActiveCN111191654ASolve the time cost and labor costImprove efficiencyCharacter and pattern recognitionNeural architecturesGenerative adversarial networkImage based

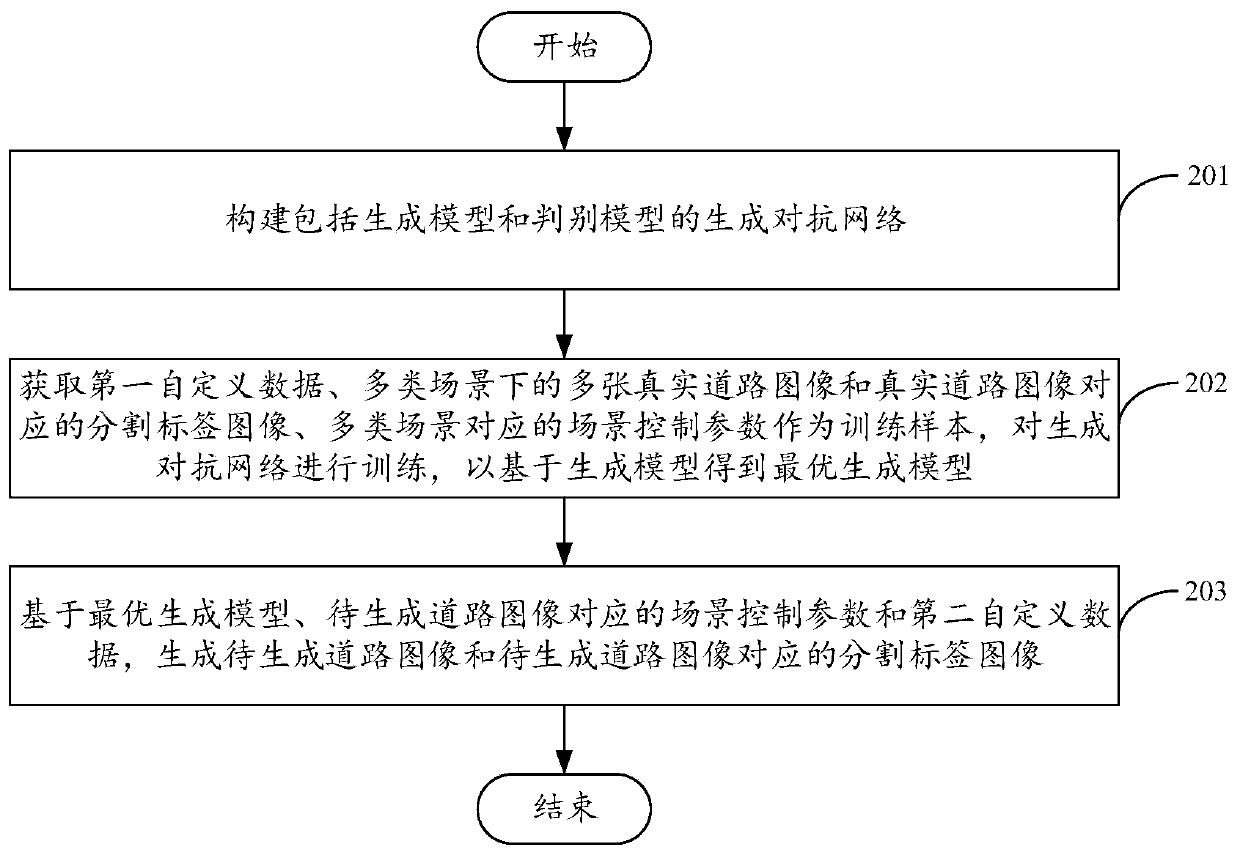

The invention provides a road data generation method and device, electronic equipment and a storage medium. The method comprises the steps of constructing a generative adversarial network comprising ageneration model and a discrimination model; obtaining first custom data, a plurality of real road images in multiple types of scenes, segmentation label images corresponding to the real road imagesand scene control parameters corresponding to the multiple types of scenes as training samples, and training the generative adversarial network to obtain an optimal generation model based on the generation model, wherein the scene control parameters represent scene types; generating a to-be-generated road image and a segmentation label image corresponding to the to-be-generated road image based onthe optimal generation model, the scene control parameter corresponding to the to-be-generated road image and the second custom data, wherein the first custom data and the second custom data have thesame distribution rule. According to the invention, the problem that the time cost and the labor cost are high when road images of a specific scene and corresponding traffic line labels are obtainedcan be solved, and the road data obtaining efficiency is improved.

Owner:重庆紫光华山智安科技有限公司

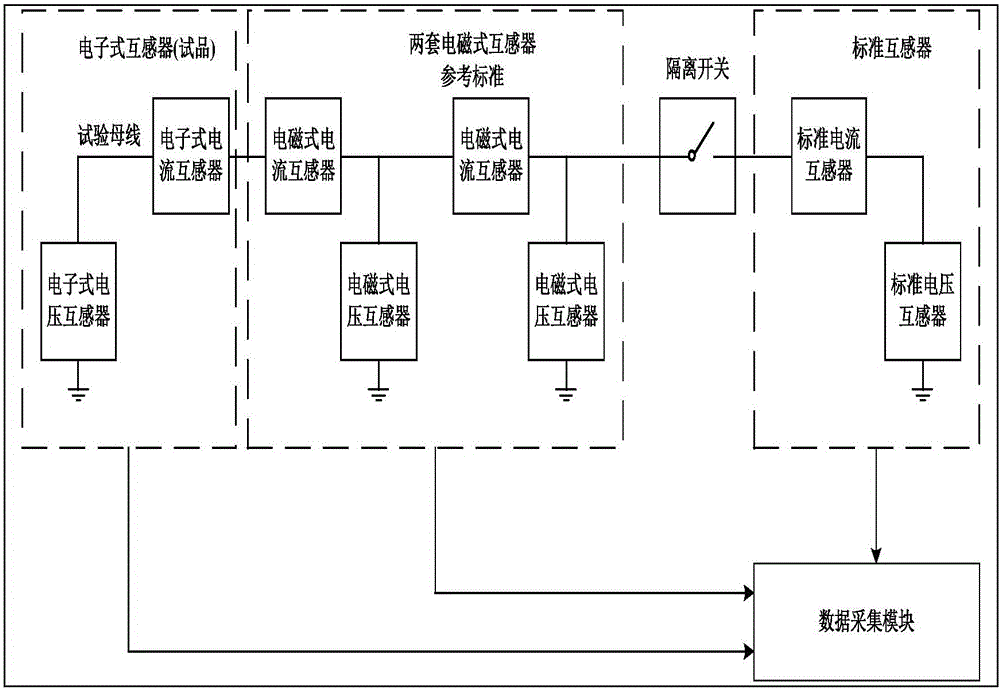

Electronic mutual inductor error characteristic on-line comparison and calibration device and method

ActiveCN105842644AReduce the difficulty of operation and maintenanceReduce operation and maintenance costsElectrical measurementsTest comparisonComputer module

The invention provides an electronic mutual inductor error characteristic on-line comparison and calibration device. The device comprises an electronic mutual inductor module, an electromagnetic mutual inductor reference standard module, a standard mutual inductor module and a data acquisition module; one end of an isolating switch is connected with the electromagnetic mutual inductor reference standard module which is connected with the electronic mutual inductor module, and the other end is connected with the standard mutual inductor module; the data acquisition module is connected with the electronic mutual inductor module, the electromagnetic mutual inductor reference standard module, and the standard mutual inductor module. By means of the device and the method, the accuracy and reliability of electronic mutual inductor operation data on-line comparison and calibration are improved, and reliable data support is provided for reasonable and accurate estimation of electronic mutual inductor error characteristics.

Owner:CHINA ELECTRIC POWER RES INST +2

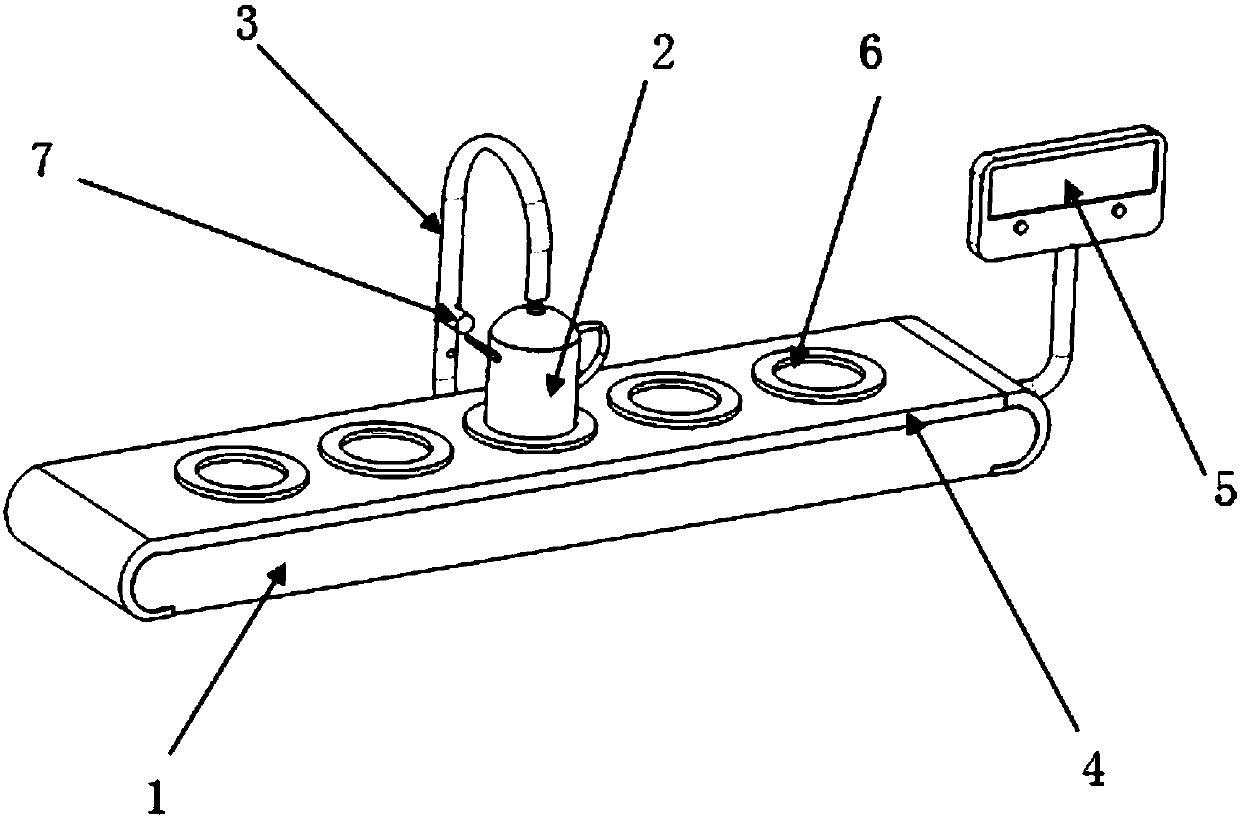

Automatic tea making method and automatic tea tray system for realizing same

InactiveCN107713590AFlexible adjustmentReduce manual operationsDomestic vesselsAgricultural engineeringThermal water

The invention discloses an automatic tea making method and an automatic tea tray system for realizing the same. The method comprises the steps of putting different varieties of tea leaves into different teapots respectively, and injecting hot water into the teapots for making tea; and the method particularly comprises the steps of identifying the teapots with different varieties of tea leaves, andautomatically injecting hot water with different temperatures into the teapots according to different varieties of tea leaves. The automatic tea tray system comprises a tea tray, a teapot put on thetea tray, a water injection system arranged at one side of the tea tray, a delivery device arranged on the tea tray and used for delivering the teapot, and a control terminal electrically connected with the water injection system and the delivery device, wherein the control terminal is used for controlling transmission of a water injection switch of the water injection system and the delivery device; and the water injection system is provided with a water temperature adjusting device for adjusting the output water temperature, and the water temperature adjusting device receives an output watertemperature signal sent by the control terminal. The method and the tea tray system can automatically identify the variety of the made tea so as to automatically inject hot water with different temperatures into the teapot according to different varieties of tea leaves.

Owner:SHANGHAI INST OF TECH

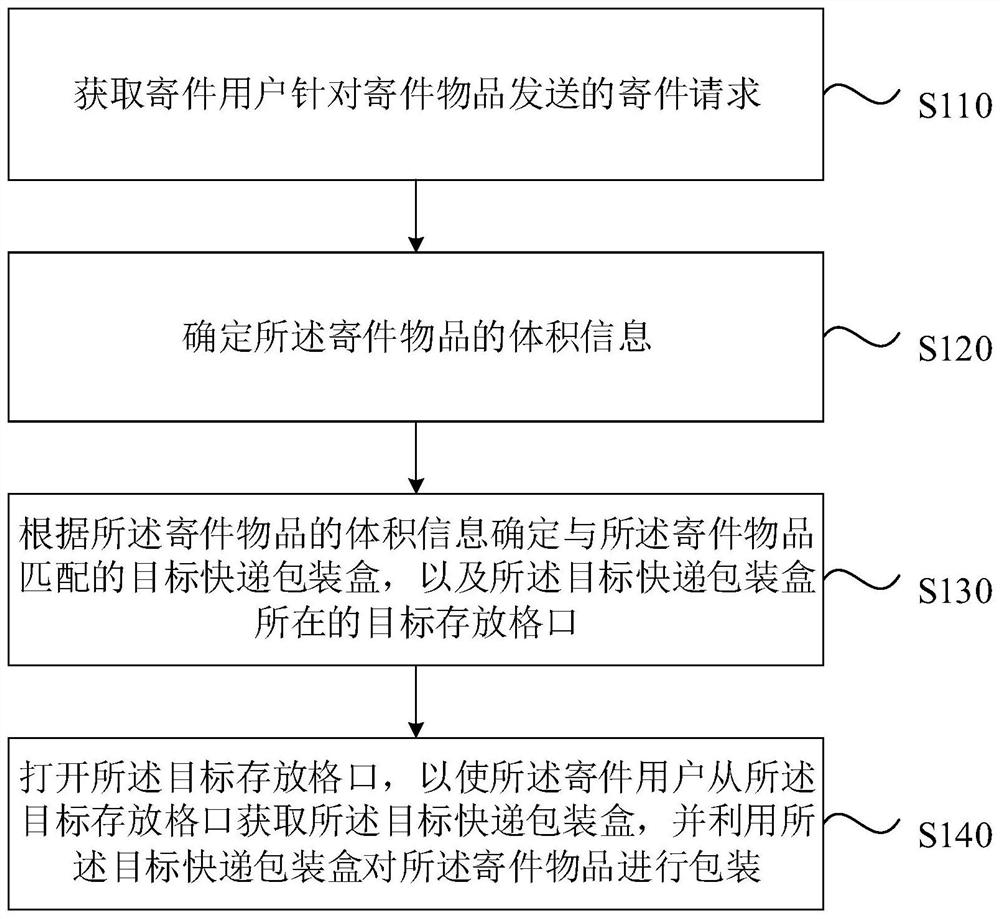

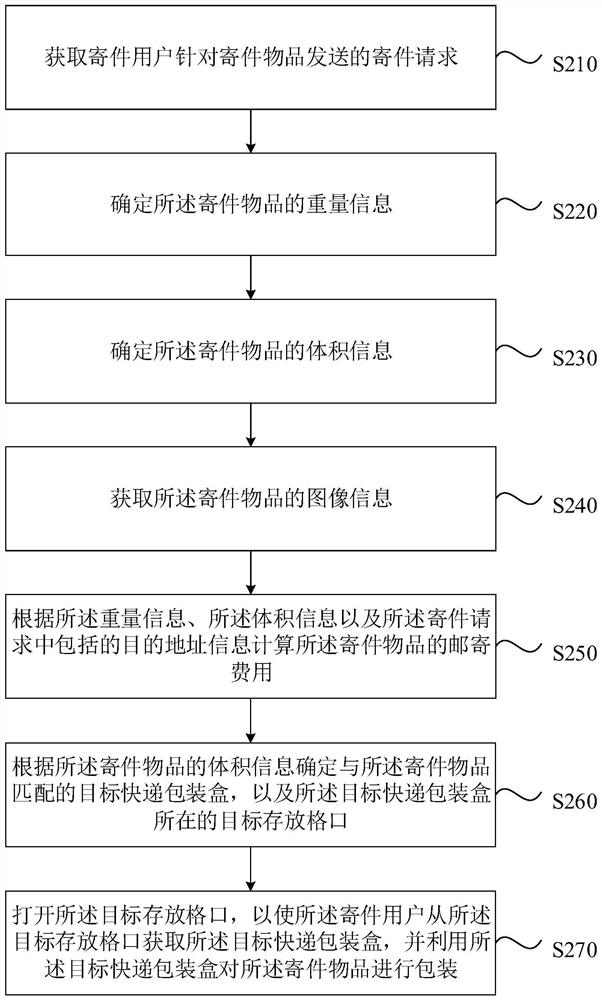

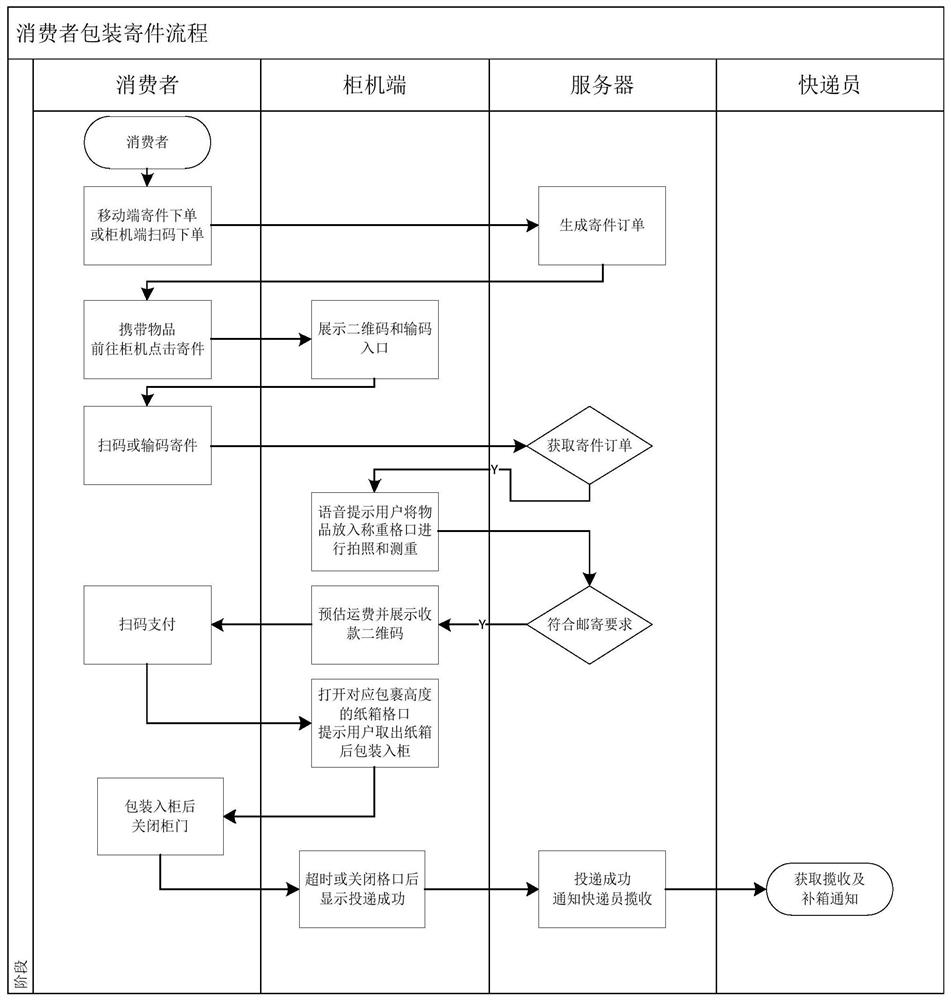

Express packaging box processing method and device, express cabinet and storage medium

PendingCN111754260AImprove collection efficiencyReduce hardware costsApparatus for meter-controlled dispensingLogisticsComputer hardwareOperating system

The embodiment of the invention discloses an express packaging box processing method and device, an express cabinet and a storage medium. The method comprises the steps: acquiring a sending request sent by a sending user for a sent article; determining volume information of the sent article; determining a target express packaging box matching the sent article and a target storage grid where the target express packaging box is located according to the volume information of the sent article, the target storage grid being a grid opening for storing express items, in an express cabinet; and opening the target storage grid to enable the sending user to obtain the target express packaging box from the target storage grid, and packaging the sent article by utilizing the target express packaging box. According to the technical scheme of the embodiment of the invention, the receiving efficiency of the deliveryman can be improved, and the hardware cost of the express cabinet is reduced.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

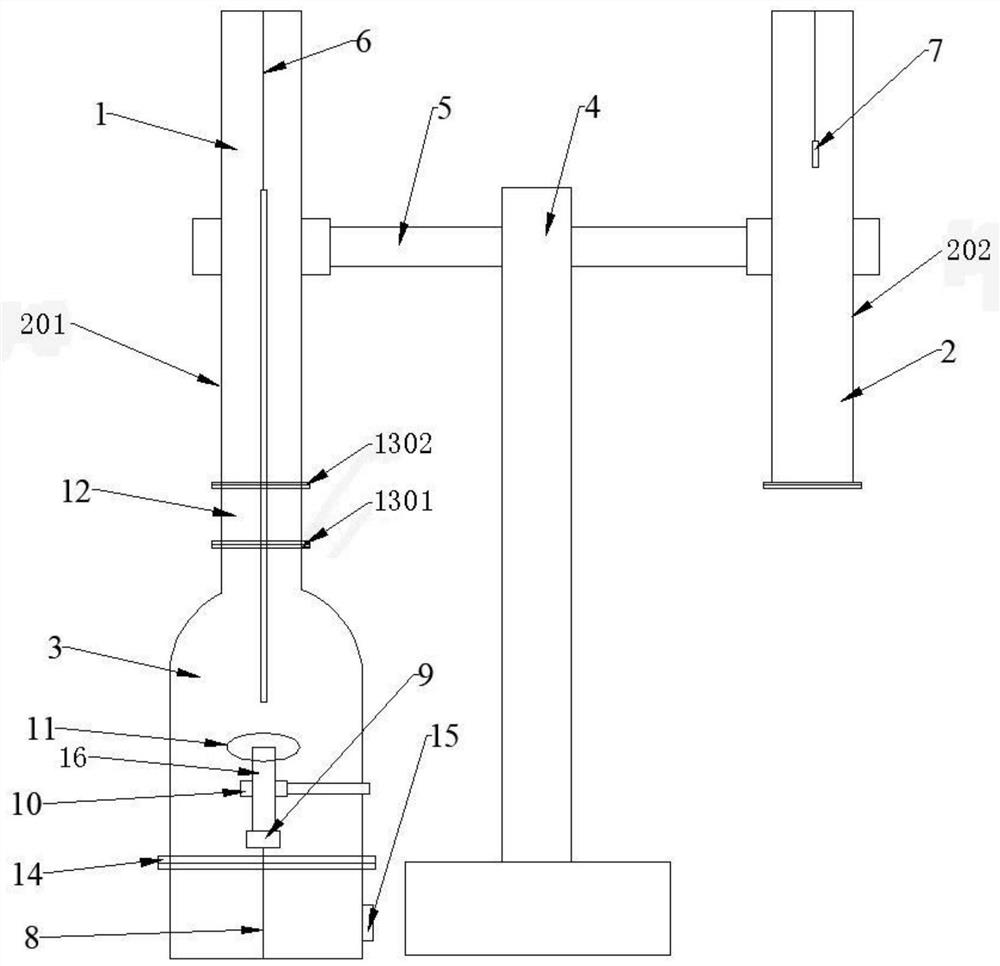

Silicon core furnace capable of realizing continuous production, and using method

InactiveCN111945223ASolve time costImprove efficiencyPolycrystalline material growthSingle crystal growth detailsSiliconMaterials science

The invention discloses a silicon core furnace capable of continuous production, and a use method. The silicon core furnace comprises: a lower furnace body internally provided with a silicon core drawing device, wherein the upper part of the lower furnace body is provided with a first partition plate capable of being opened and closed, at least two upper furnace bodies detachably connected with the lower furnace body; and an environment control device for carrying out environment control on the lower furnace body and the upper furnace body which is not provided with the lower furnace body. According to the invention, the furnace body is divided into two detachable parts, in the silicon core drawing process, environment control is conducted on one upper furnace body, and compared with the prior art that the furnace body is divided into two fixedly-connected parts, the mode of the invention can solve the problem of time cost (the whole silicon core furnace drawing process needs about 5 h, the heating material melting process lasts for about 30 min, and the furnace dismounting and replacing process lasts for about 30 min), and can solve the problems of energy cost and resource cost waste (reducing empty burning of the raw material rod in the silicon core drawing device and effectively utilizing the lower half part of the raw material rod).

Owner:ASIA SILICON QINGHAI +1

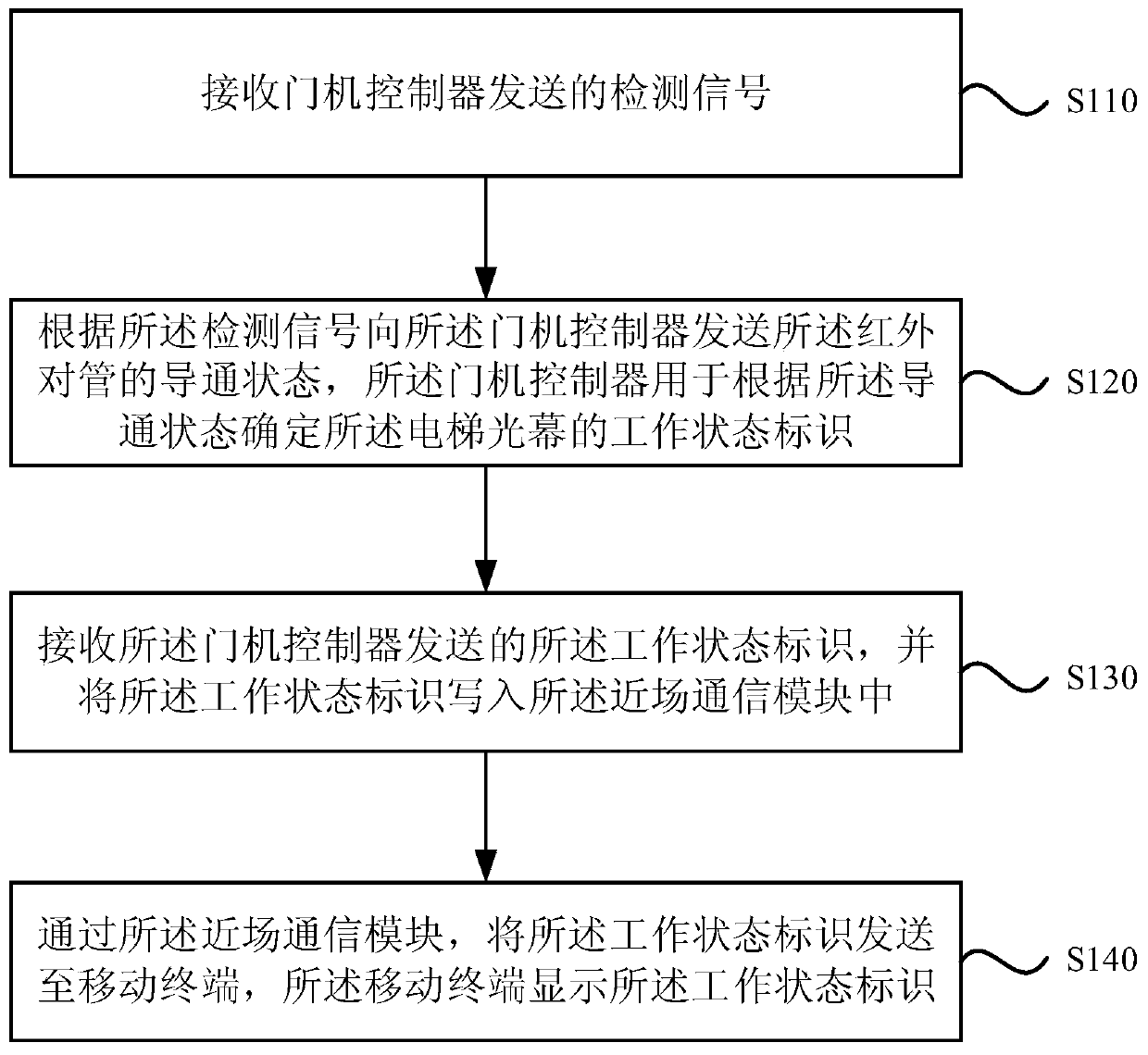

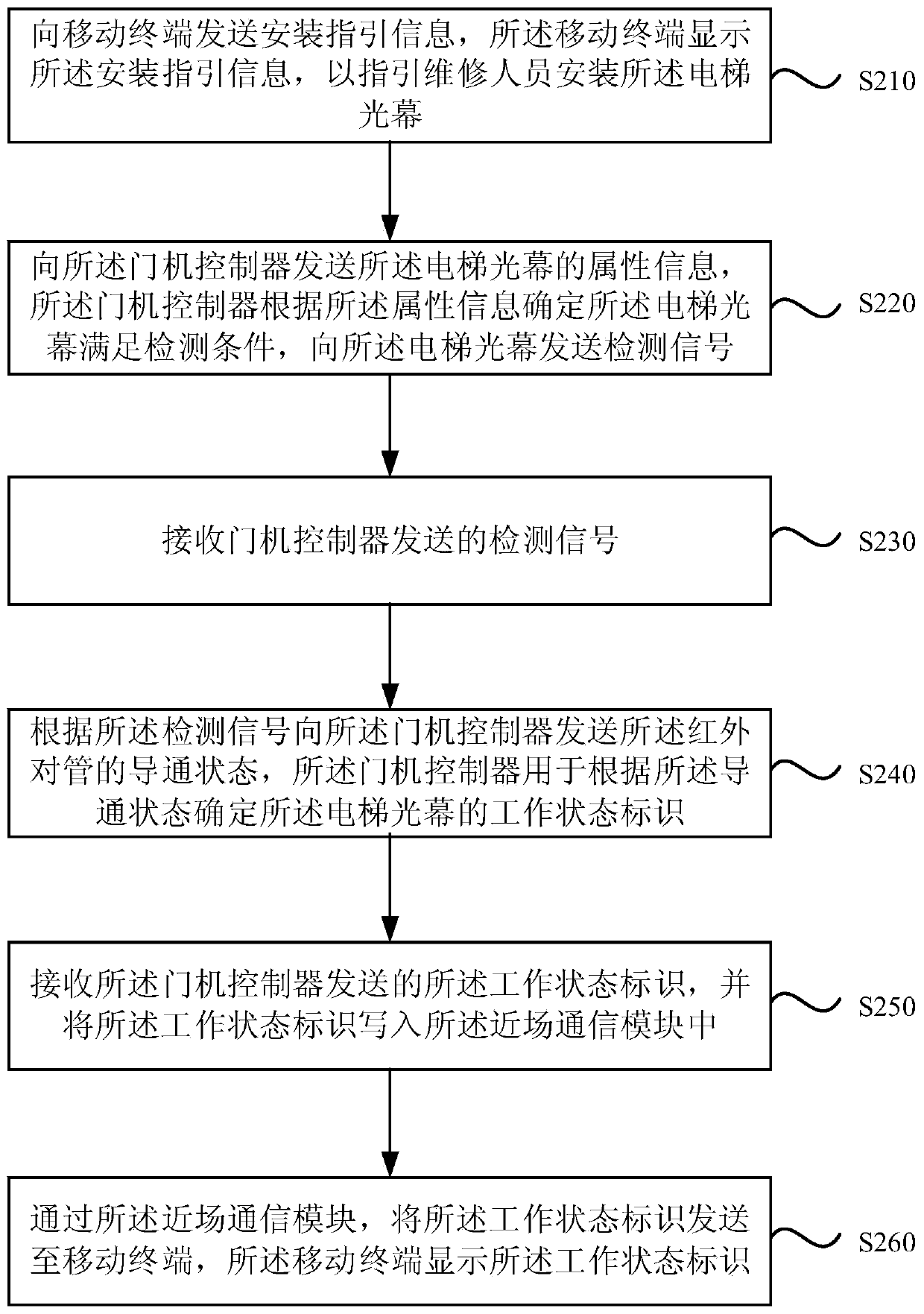

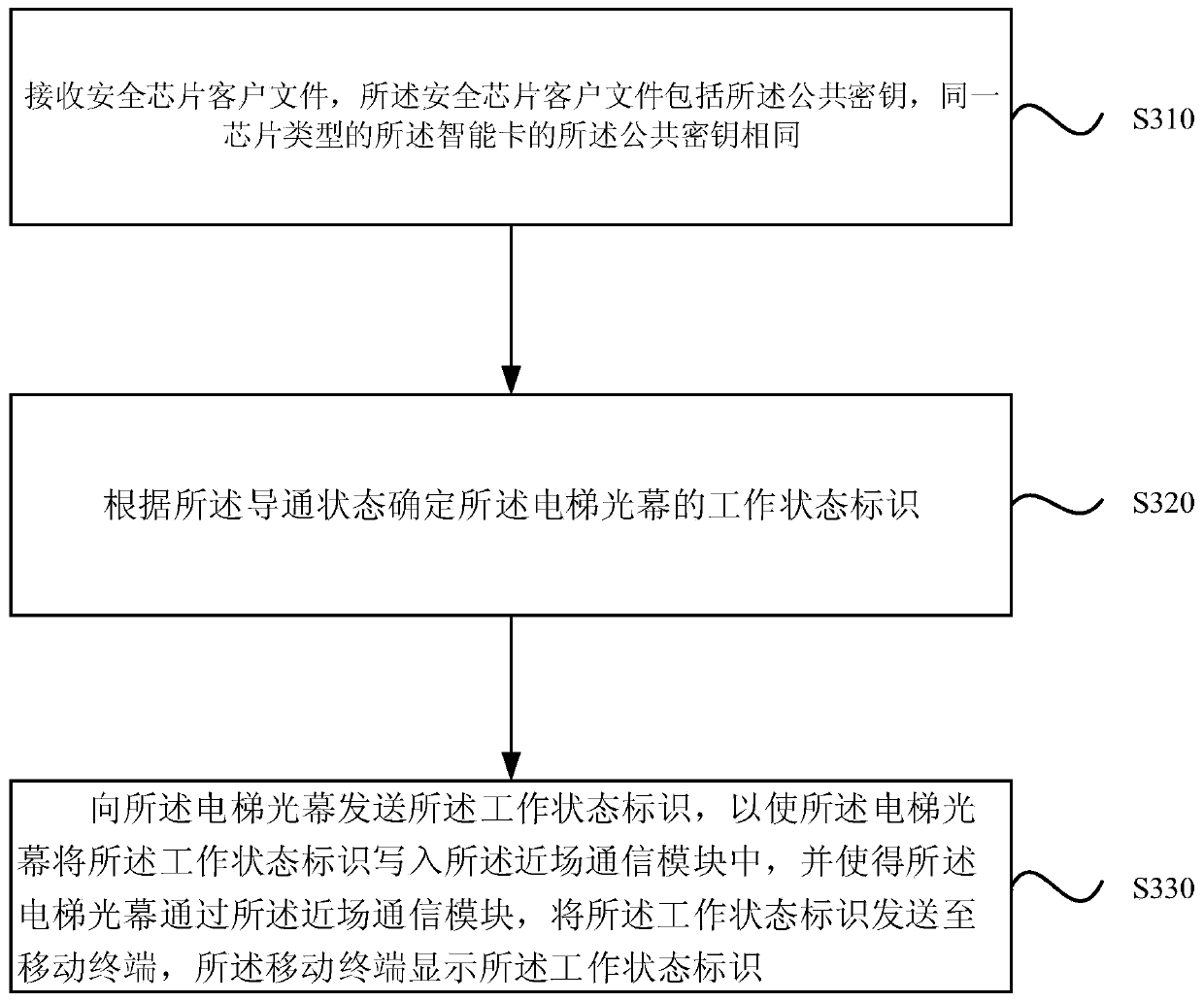

Processing method based on elevator light curtain and related equipment

InactiveCN109969892ASolve time costImprove detection efficiencyElevatorsBuilding liftsComputer moduleComputer terminal

The embodiment of the invention discloses a processing method based on an elevator light curtain and related equipment. The elevator light curtain is internally provided with a near field communication module and infrared tubes. The method includes the steps of receiving a detection signal sent by a door machine controller; transmitting the conducting state of the infrared tubes to the door machine controller according to the detection signal, wherein the door machine controller is used for determining an operating state identifier of the elevator light curtain according to the conducting state; receiving the operating state identifier sent by the door machine controller, and writing the operating state identifier into the near field communication module; and sending the operating state identifier to a mobile terminal through the near field communication module, and enabling the mobile terminal to display the operating state identifier. The problem that time is cost is caused by the fact that multiple fault detection is required due to the fact that the elevator light curtain does not record the fault conditions is solved, convenience is brought for maintenance personnel to detectthe elevator light curtain, the detection efficiency is increased, and the maintenance cost is reduced.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

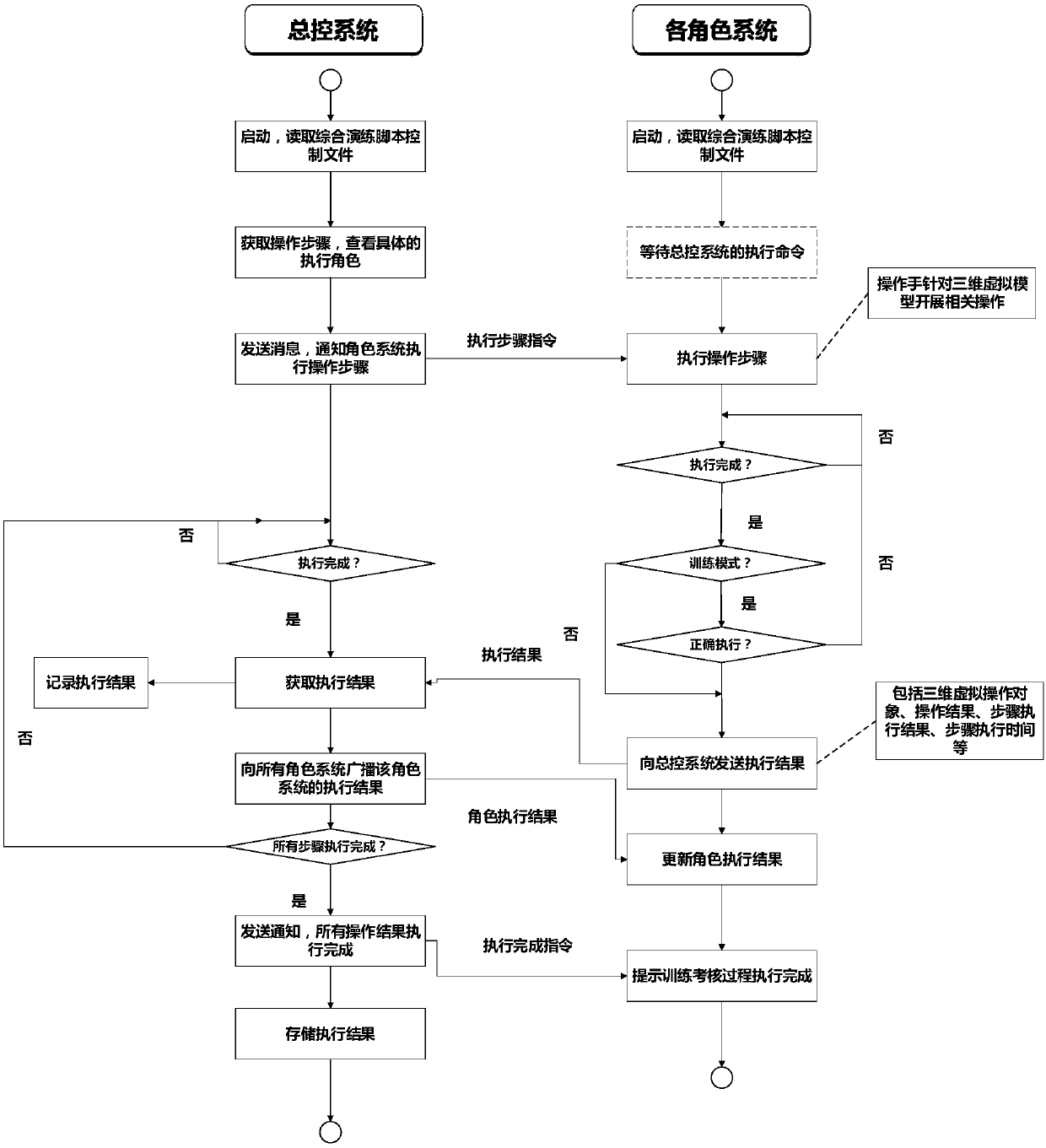

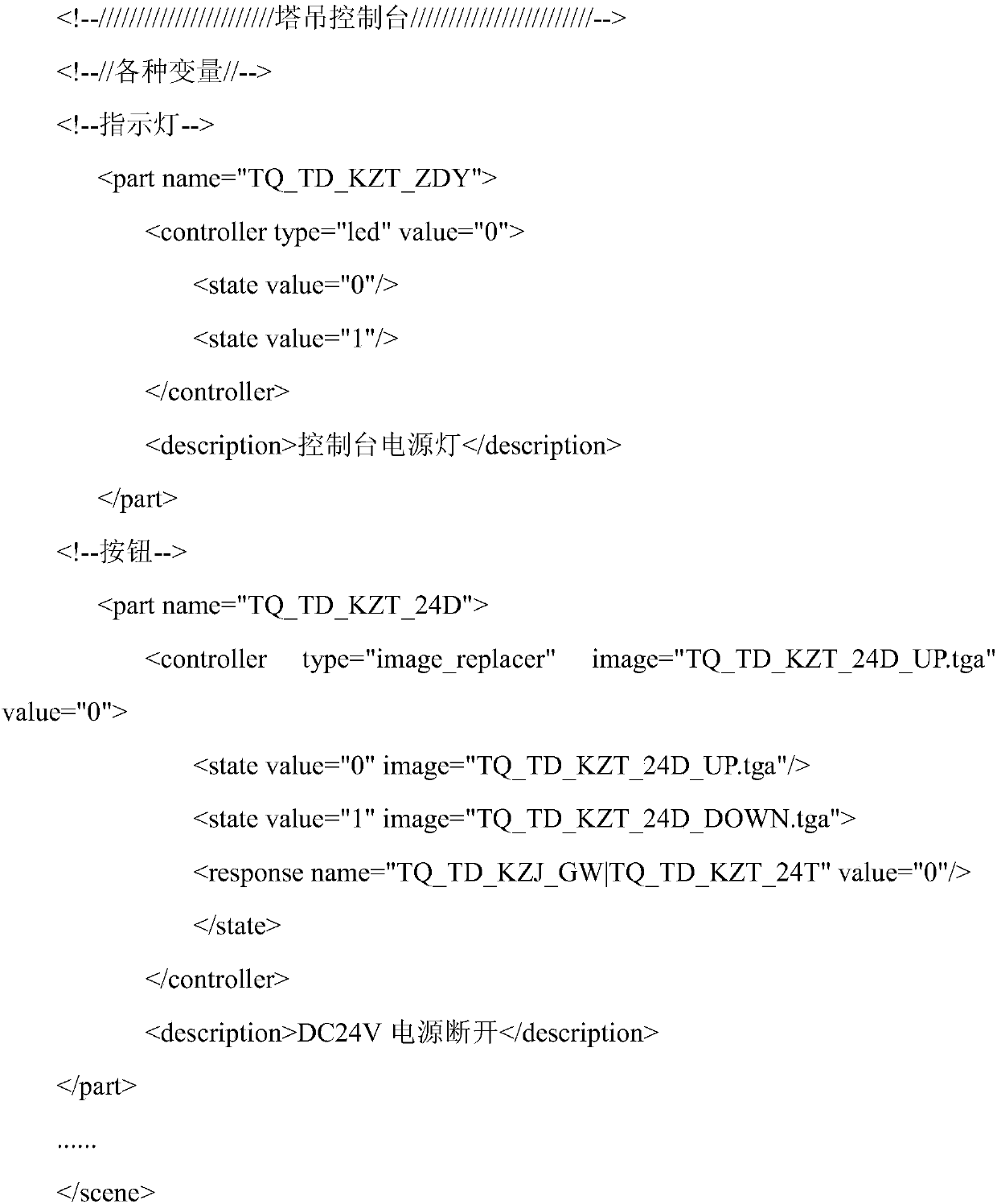

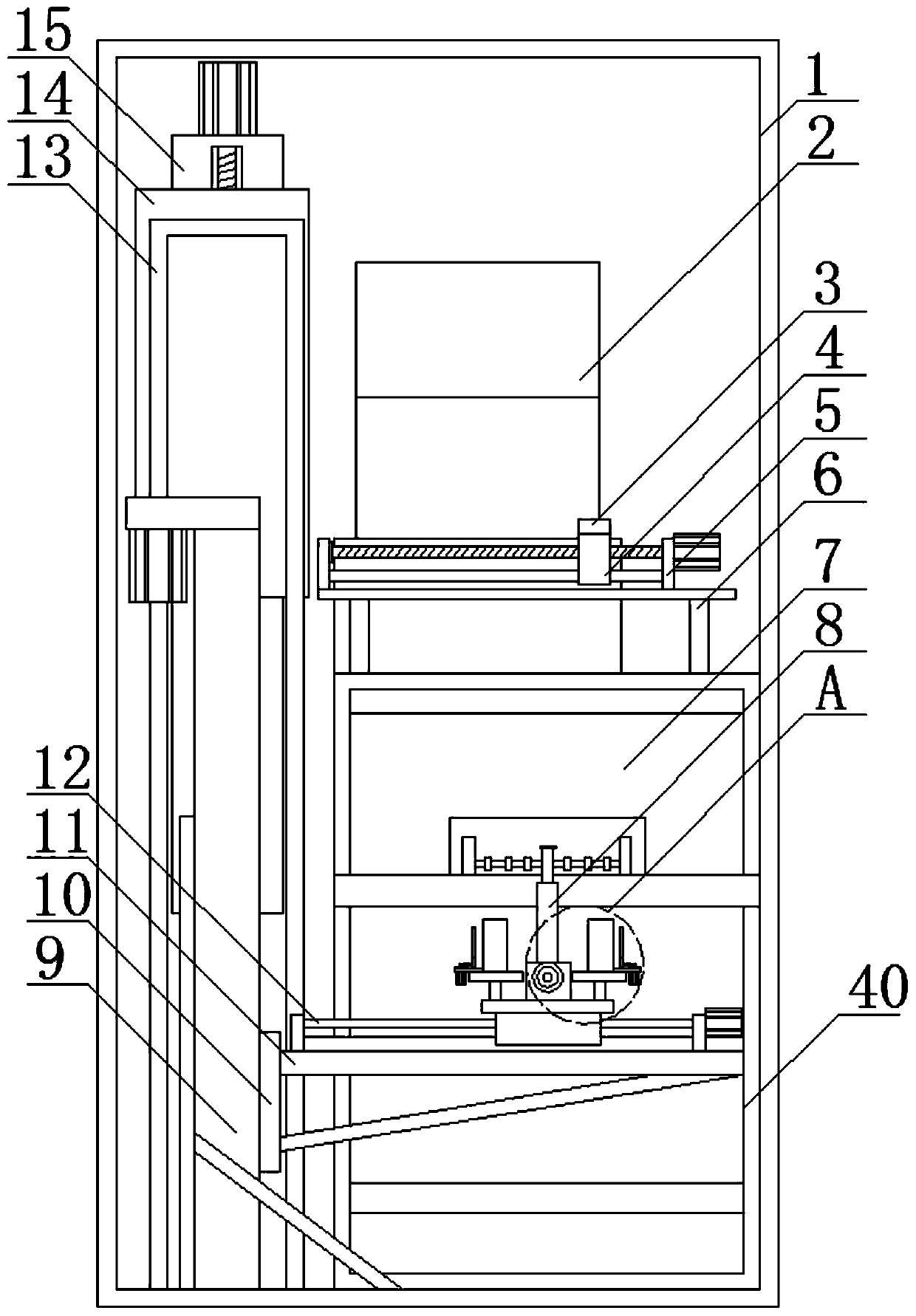

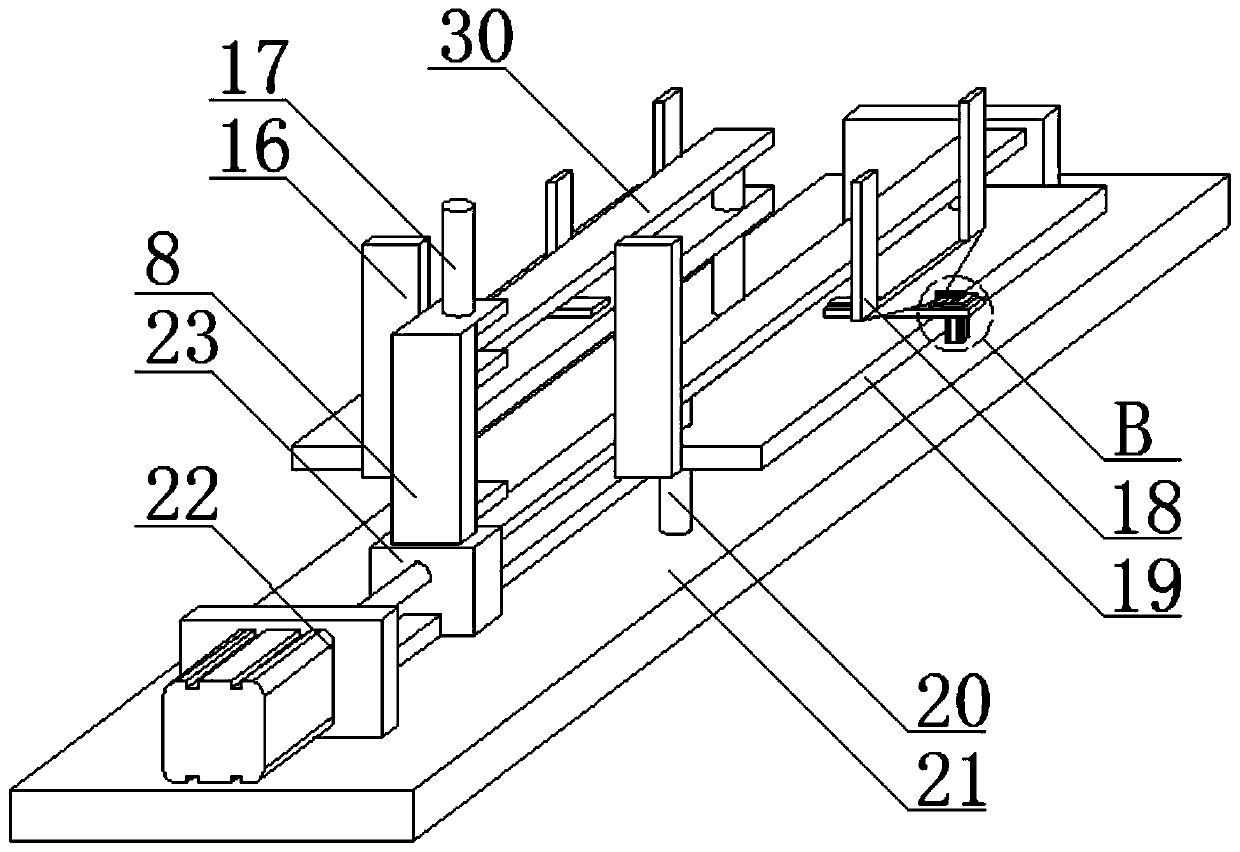

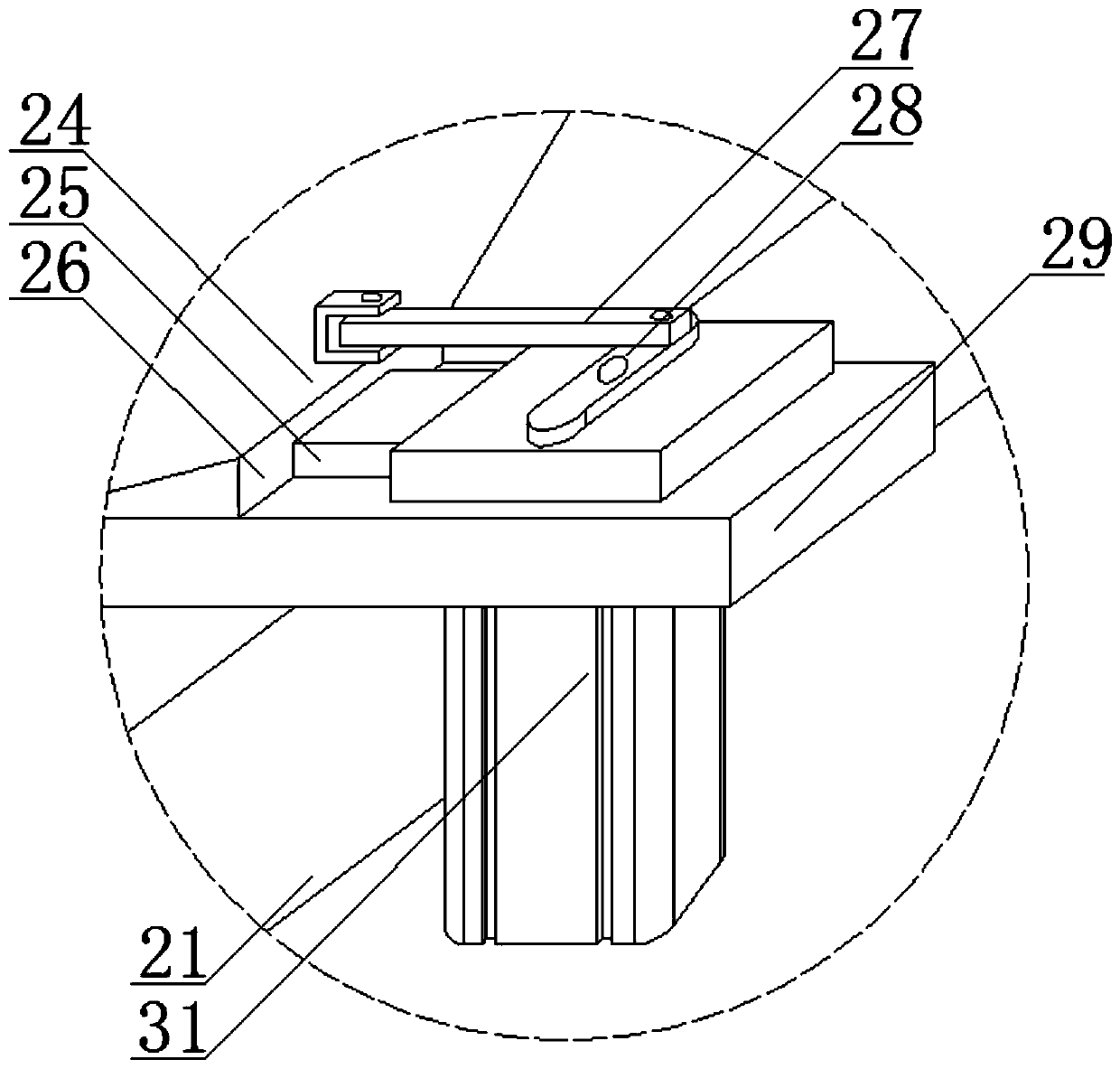

Space launch site comprehensive drill system and realization method thereof

InactiveCN107945606AAddress site costsSolve time costCosmonautic condition simulationsSimulatorsSpace launchExecution unit

The invention relates to a space launch site comprehensive drill system, comprising a master control subsystem and one or more role subsystems for respectively reading a predefined comprehensive drillscript control file. The script control file includes one or more operation steps. The master control subsystem selects the first operation step and its associated role subsystem, and sends the execution instruction of the first operation step to the role subsystem; the post operator is prompted to execute the first operation step; in response to the execution of the first operation step by the post operator, the role subsystem performs a preconfigured action and sends the execution result to the master control subsystem; the master control subsystem broadcasts the execution result to the oneor more role subsystems; the one or more character subsystems update the execution status of the role subsystem; and the master control subsystem selects the next operation step and repeats the abovesteps until all the operation steps in the script control file are completed.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

Printing and binding integrated machine

PendingCN110978814AEasy to handleReduce labor costsTypewritersBook making processesComputer printingEngineering

The invention discloses a printing and binding integrated machine which comprises a shell. A mounting rack, a second electric sliding table and a second supporting rack are fixed to the bottom in theshell, a printer is mounted in the mounting rack, a binding machine is mounted at the upper end of the mounting rack, a second slide block is mounted on the second electric sliding table, a first supporting plate is fixed to the second slide block, the first supporting plate is located on one side of an outlet of a printer, a third electric sliding table is mounted at the upper end of the first supporting plate, a fifth slide block is mounted on the third electric sliding table, a third supporting plate is fixed to the upper end of the fifth slide block, a fifth electric sliding table is mounted at the upper end of the third supporting plate, and a third slide block is mounted on the fifth electric sliding table. The printing and binding integrated machine in an integrated design of printing and binding is high in utilization ratio of space and small in working space, can align printed data and send the printed data into the binding machine to be bound, and transfers the bound printeddata to a storage area, so that a lot of manpower and time cost are saved, and paper is orderly and firmly bound.

Owner:吉林同益光电科技有限公司

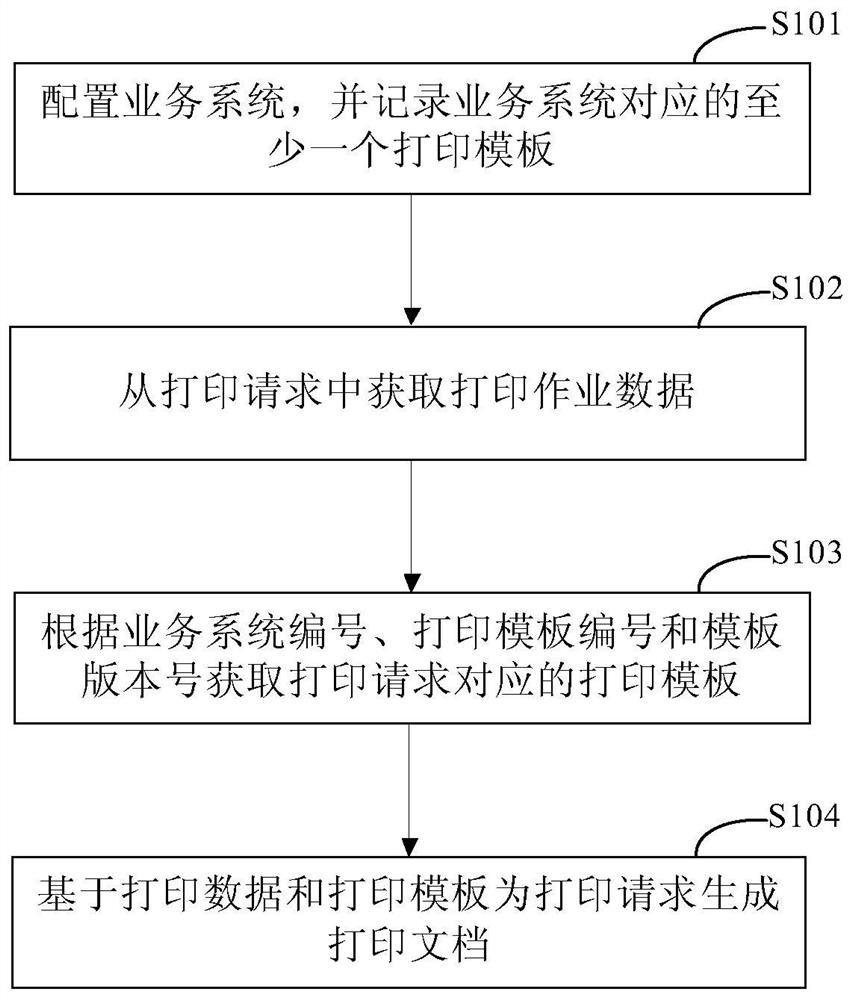

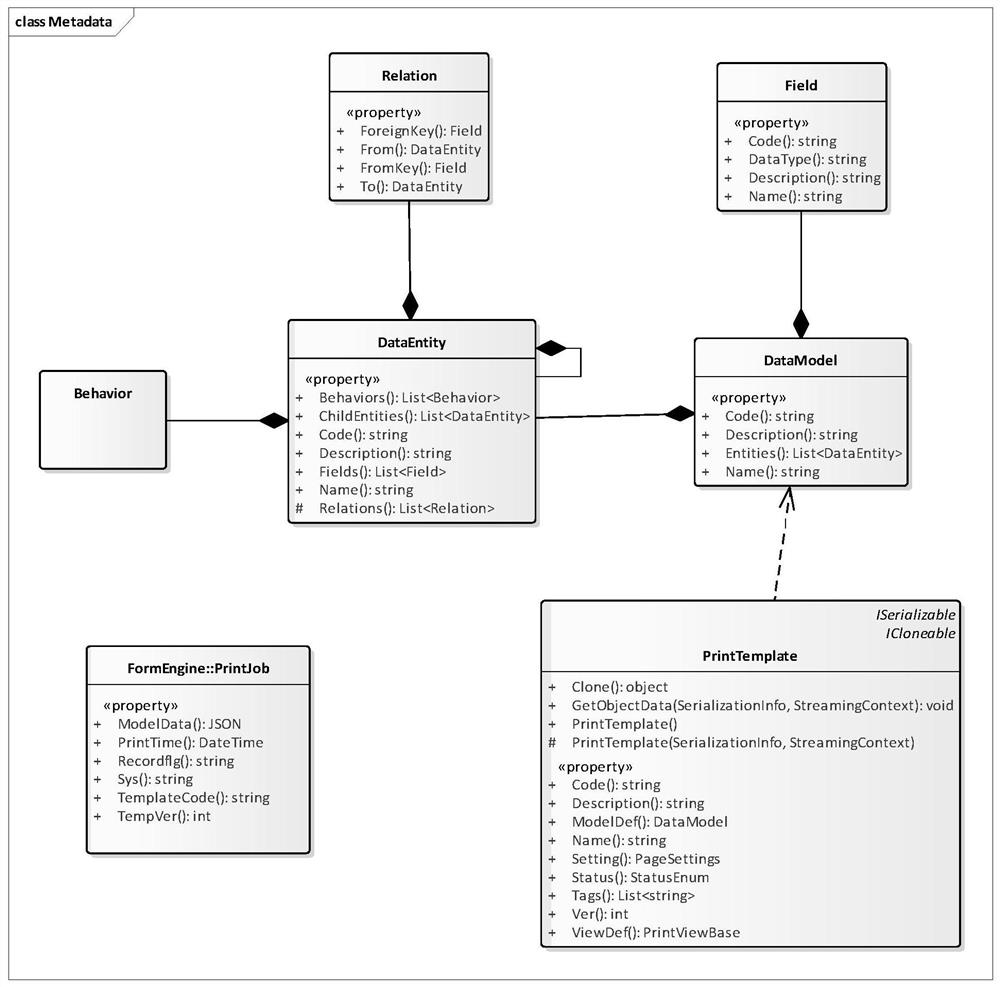

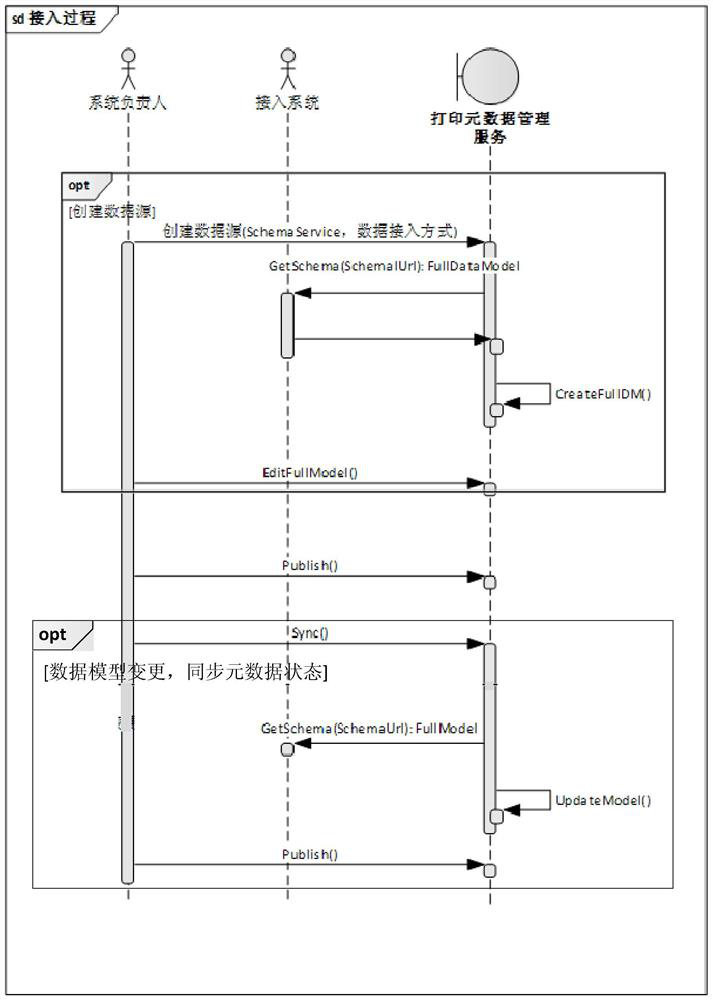

Data printing method and printing management system

PendingCN113360100AOvercoming technical issues with poor maintainabilitySolve labor costsDigital output to print unitsProcess engineeringDocumentation

The invention discloses a data printing method and a printing management system, and relates to the technical field of computers. A specific embodiment of the method comprises the following steps: configuring a business system, and recording at least one printing template corresponding to the business system; obtaining printing job data from a printing request; obtaining the printing template corresponding to the printing request according to a service system number, a printing template number and a template version number; and generating a printing document for the printing request based on the printing data and the printing template. According to the embodiment, the problem that printing requirements of different service systems in different service scenes are variable can be solved, the development and operation cost in the aspects of manpower, time and the like is reduced, and the maintainability of the service systems is improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

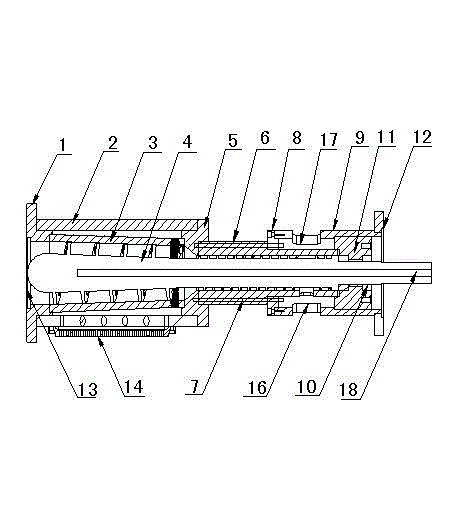

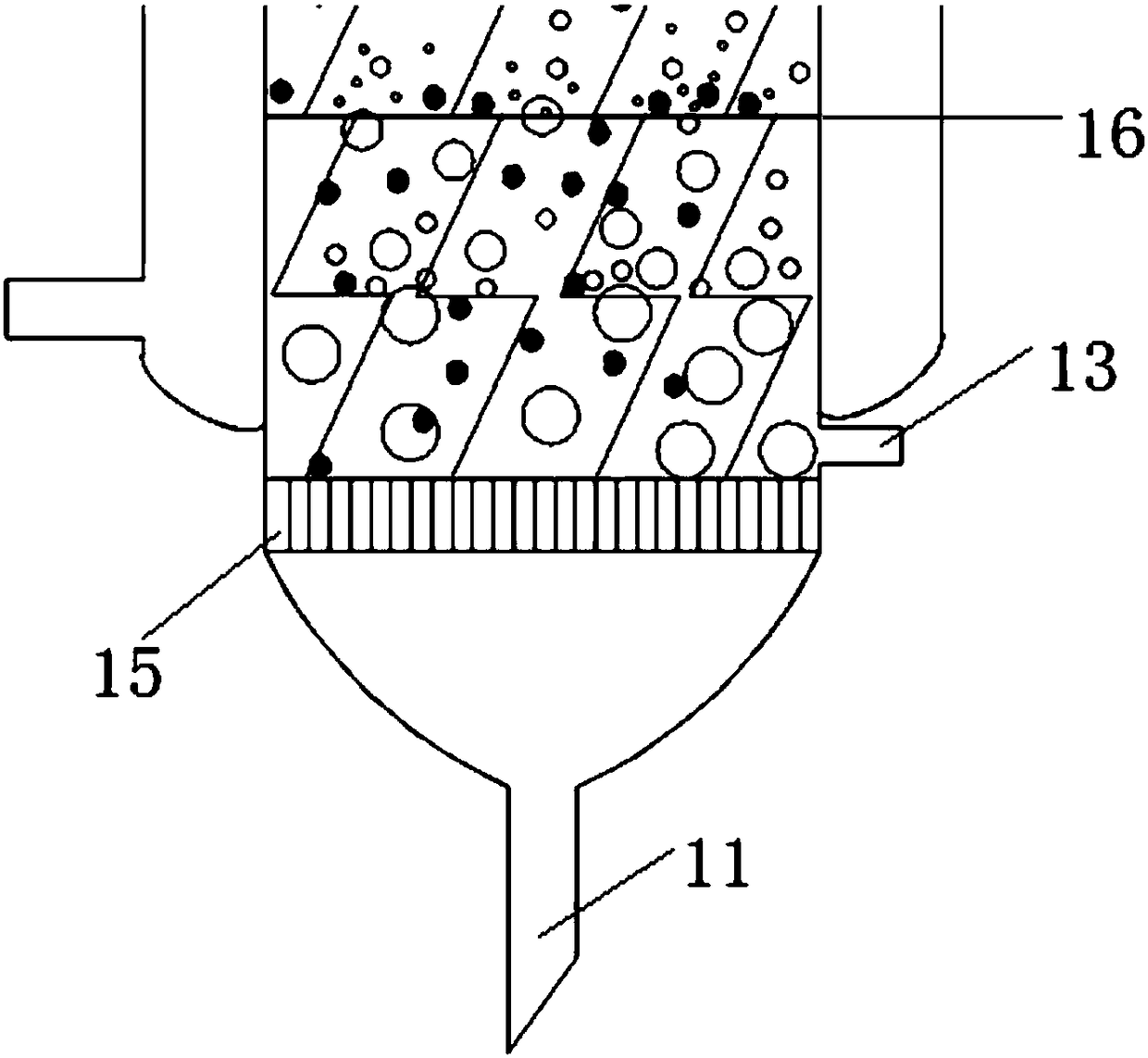

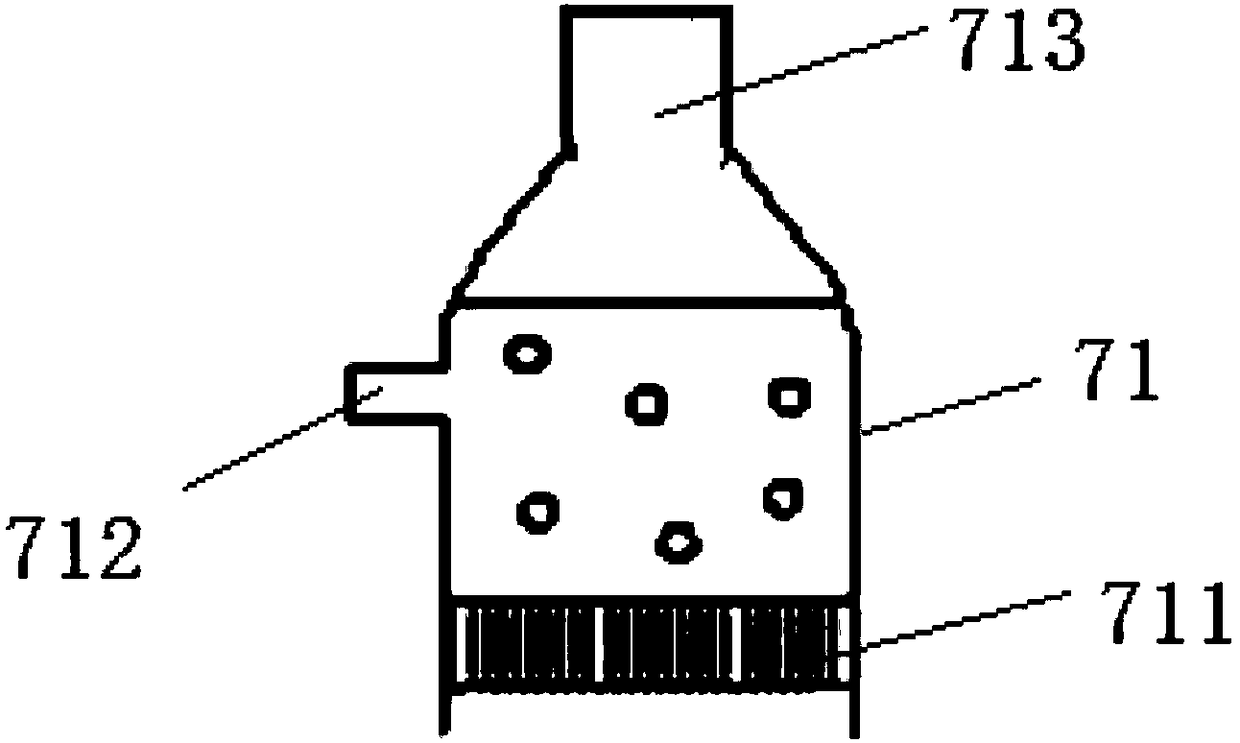

Ongoing residue filter mingled with plastic hot-melt extrusion

The invention relates to an ongoing residue filter mingled with plastic hot-melt extrusion, which comprises a filtering system, a taper reduction sleeve and a deslagging system, wherein a conic filtering sleeve is sleeved in a connecting sleeve and is provided with high density filtering holes, a screw rod is arranged in the conic filtering sleeve, the appearance of the screw rod is closely matched with that of an inner cavity of the conic filtering sleeve, the screw rod and the inner cavity of the conic filtering sleeve rotate relatively, one end of the taper reduction sleeve is connected with a taper reduction sleeve connection flange, the other end of the taper reduction sleeve is arranged in a deslagging sleeve and is fixed with a bearing support, the other end of the deslagging sleeve and a gearbox flange are fixed with each other, the bearing support is fixed in the deslagging sleeve, a thrust bearing is installed on the screw rod and is connected with the bearing support, openings are symmetrically formed in the peripheral wall of the deslagging sleeve, and an upper opening and a lower opening are respectively opposite to an exhaust vent and a deslagging port of the taper reduction sleeve. The ongoing residue filter adopts a filter body and a screw rod rotational extrusion technology, thus being capable of continuously filtering and discharging slag automatically, not only improving the production efficiency and lowering the manufacture and production cost, but also lowering the consumption, being simple in installation and maintenance, being in accordance with the requirement of environment protection, novelty and creation, and having a terrific market prospect.

Owner:上海帮容环保科技有限公司 +1

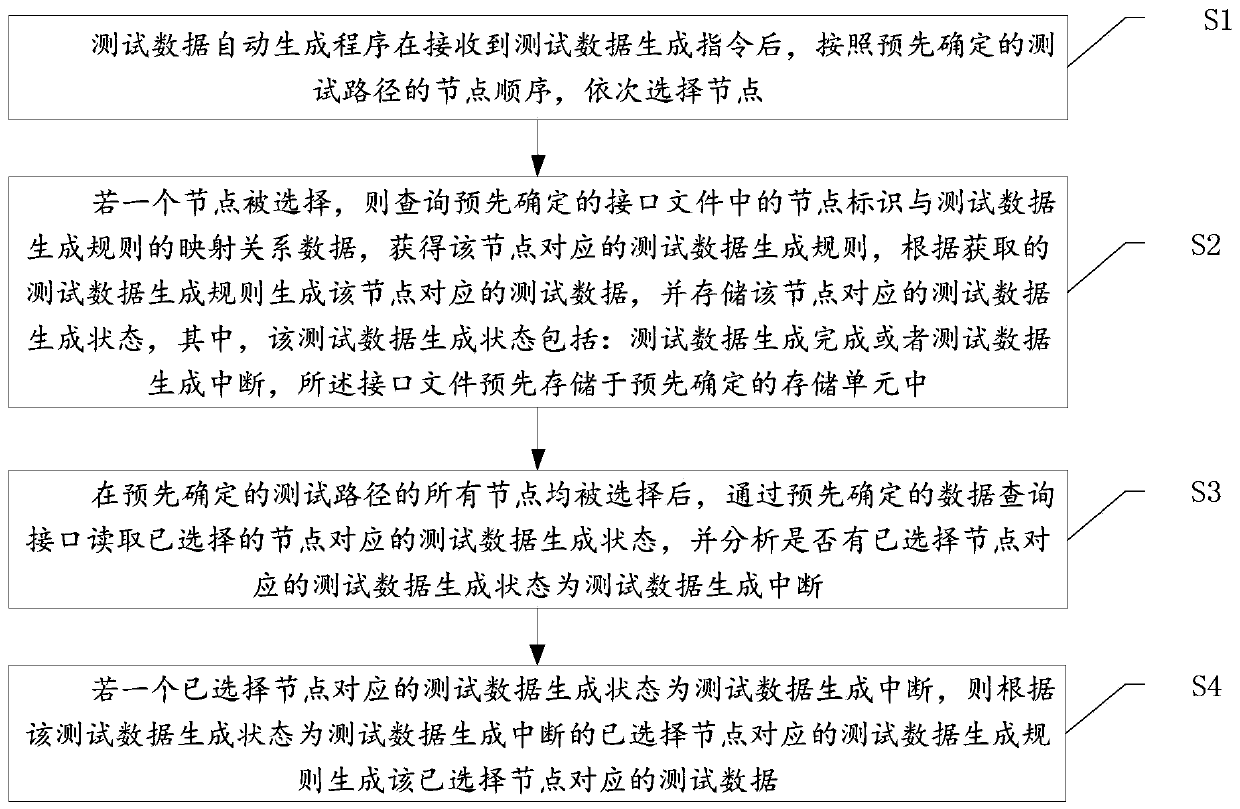

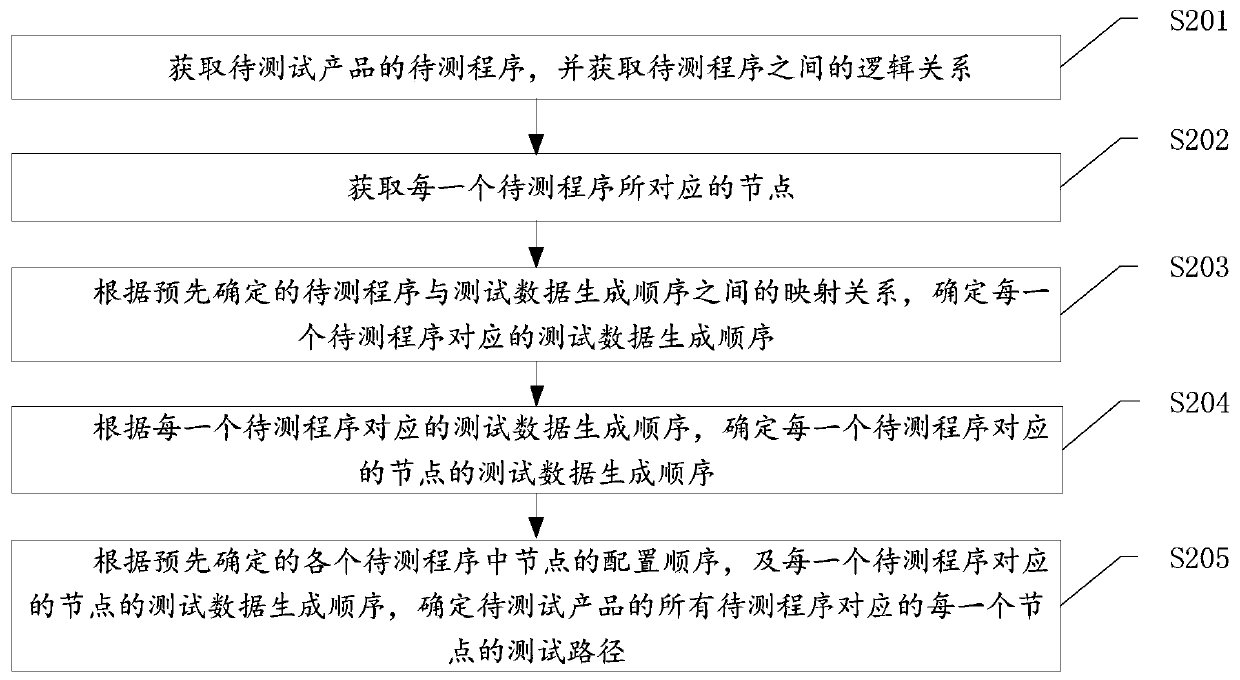

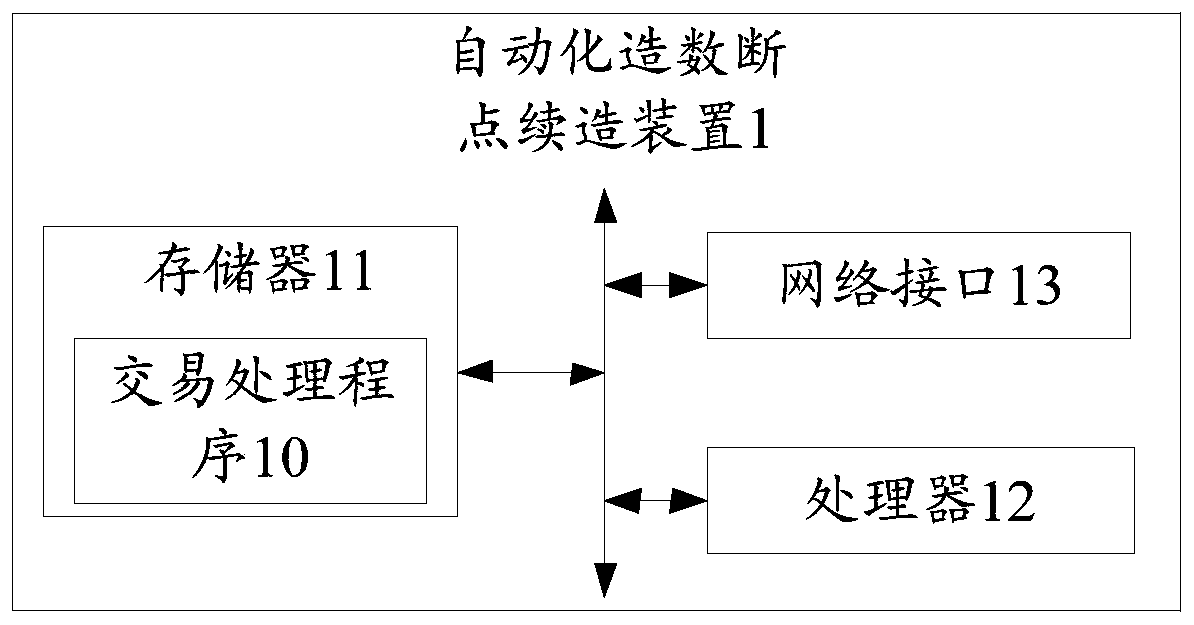

Automatic data creation breakpoint continuation method and device, and computer readable storage medium

The invention relates to the technical field of testing, and discloses an automatic data creation breakpoint continuation method, which comprises the following steps of: sequentially selecting nodes;if one node is selected, obtaining a test data generation rule corresponding to the node according to a predetermined interface file, generating test data corresponding to the node according to the obtained test data generation rule, and storing a test data generation state corresponding to the node; after all nodes of the predetermined test path are selected, reading a test data generation statecorresponding to the selected node through a predetermined data query interface; and if the test data generation state corresponding to one selected node is test data generation interruption, generating test data corresponding to the selected node according to a test data generation rule corresponding to the selected node of which the test data generation state is test data generation interruption. By utilizing the method and the device, only the test data corresponding to the interrupted node need to be generated, so that the time cost caused by data generation interruption is reduced.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

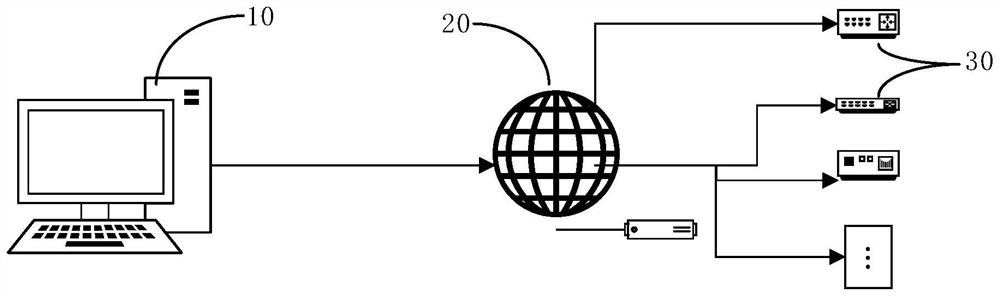

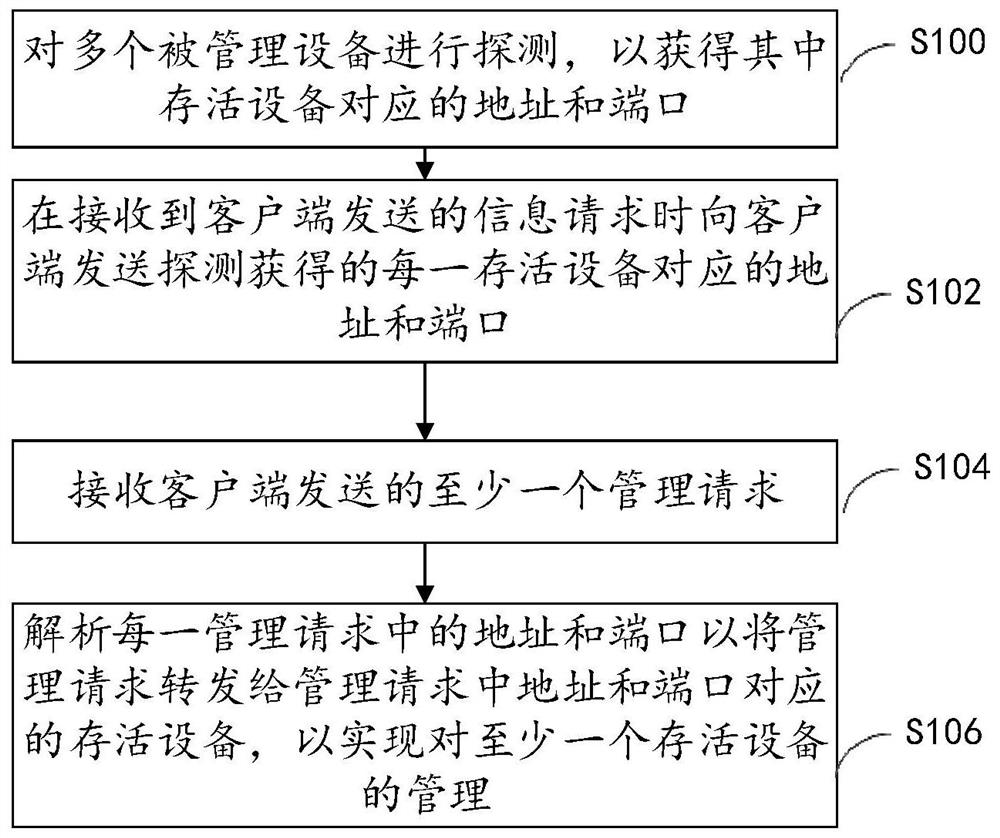

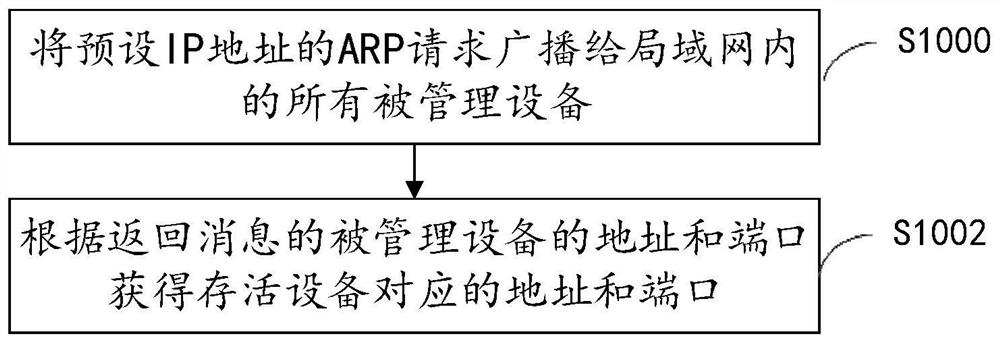

Management method and device of centralized management system, electronic equipment and storage medium

The invention provides a management method and device of a centralized management system, electronic equipment and a storage medium, the centralized management system comprises a client, a proxy server and a plurality of managed equipment, the proxy server and the plurality of managed equipment are located in the same local area network, and the method is applied to the proxy server, and comprises the steps of: detecting a plurality of managed devices to obtain addresses and ports corresponding to survival devices, wherein the survival devices represent devices with the ports currently in an open state; when an information request sent by a client is received, sending an address and a port corresponding to each survival device obtained by detection to the client; receiving at least one management request sent by the client, wherein each management request comprises an address and a port corresponding to a survival device; and analyzing the address and the port in each management request so as to forward the management request to the survival device corresponding to the address and the port in the management request, thereby realizing management of at least one survival device.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH +2

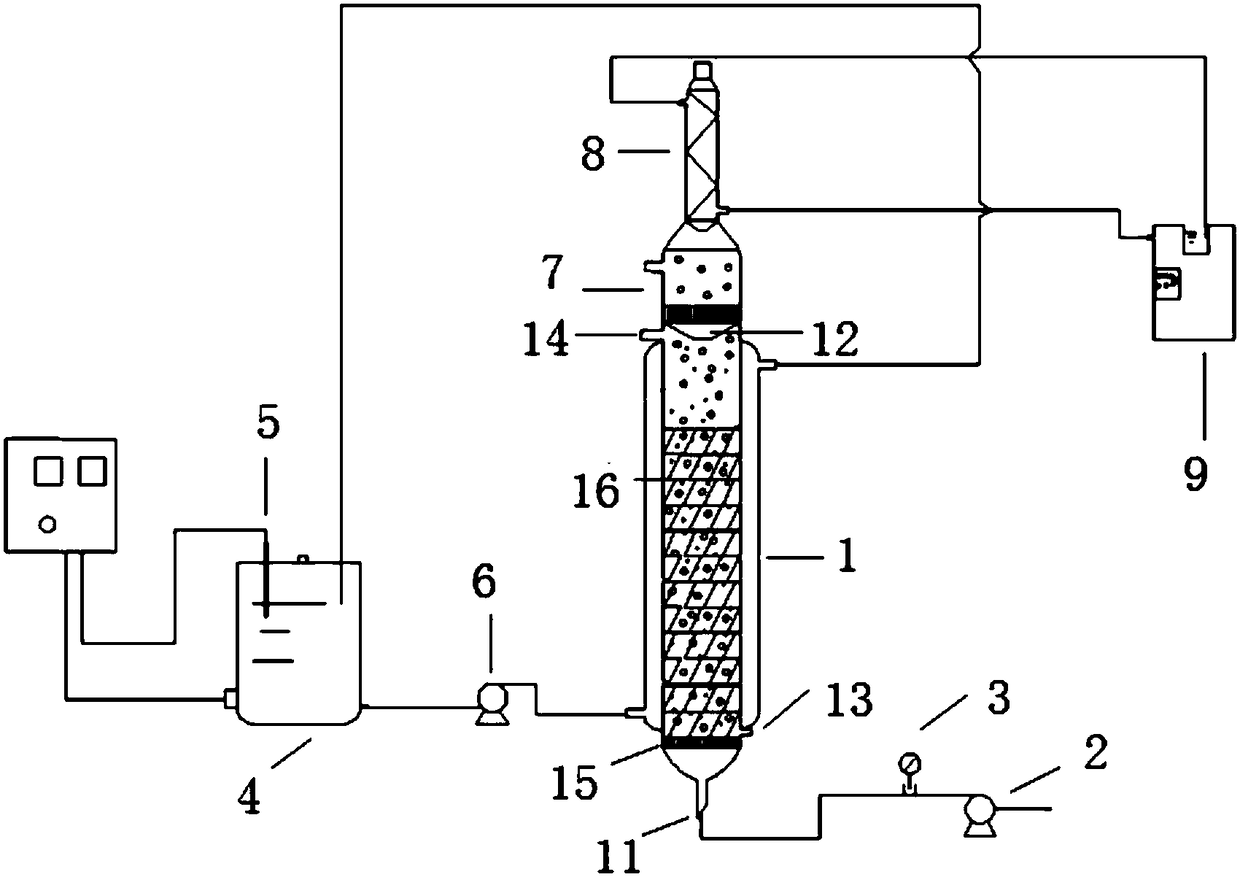

Nonaqueous phase oil product deep desulfurizing device and desulfurizing process

InactiveCN109504426AFacilitated mass transfer mixing effectBreak up bubblesRefining with oxygen compoundsHydrocarbon oils treatmentCatalytic oxidationOil phase

The invention provides a nonaqueous phase oil product deep desulfurizing device and a desulfurizing process. The process comprises the following steps: adding an oil product into a desulfurizing device, introducing a gas oxidizing agent into the oil product, performing an oxidizing-desulfurizing process in the presence of a catalyst under the set reaction condition. By adopting the nonaqueous phase oil product deep desulfurizing device, the phenomenon of emulsification of the oil phase and water phase in the catalytic oxidation of the oil product for desulfurizing is avoided, and the sulphur content in oil product can be lowered to 10 ppm or less by using molecular oxygen biomimetic catalysis.

Owner:BEIJING UNIV OF CHEM TECH

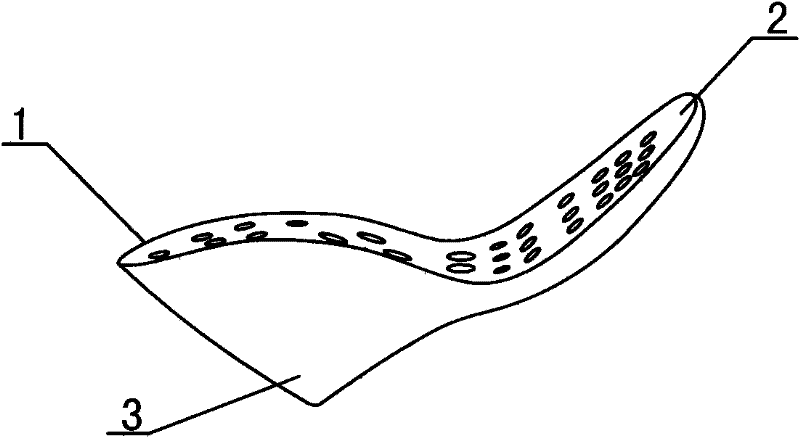

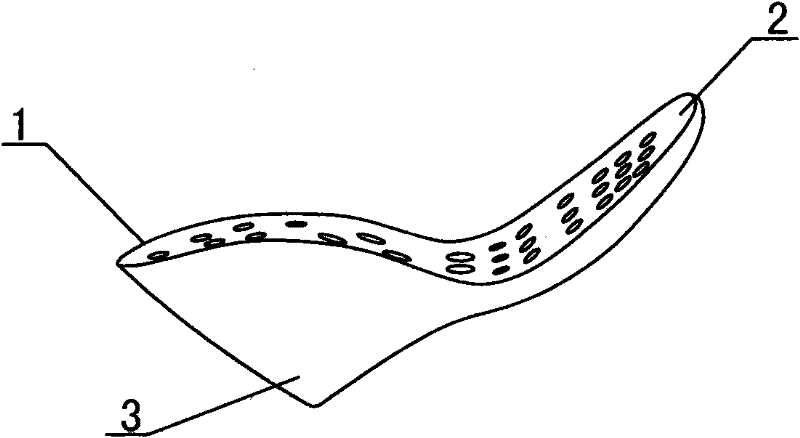

Novel sole production method

InactiveCN102173074APhysical and mechanical properties unchangedLow costDomestic footwearElectricityFoaming agent

The invention relates to a novel sole production method, which mainly comprises the following steps of: respectively preparing a rear part hard material and a front part soft material, wherein the rear part hard material consists of mixed isocyanate, mixed polyalcohol and additives, and the additives comprise an amine catalyst, a metal amine catalyst, glycol, talcpowder, a foaming agent and color cream; regulating reaction time of the hard material to be about 15 seconds, and curing within 3-5 minutes; and lifting the front tip of a die body 45 degrees relative to the ground, injecting the hard material for about 10-12 seconds, injecting the soft material, performing die assembly for 6 to 7 minutes, and demoulding. The novel sole production method has the advantages that: two types of soles with different hardness are manufactured in a once molding mode, the problem of electricity, labor and time cost due to post forming required by common dual density is solved, the problem that several dual density production processes cannot be used structurally is solved, and the mold cost is greatly saved.

Owner:佛山市南海建诺鞋业有限公司

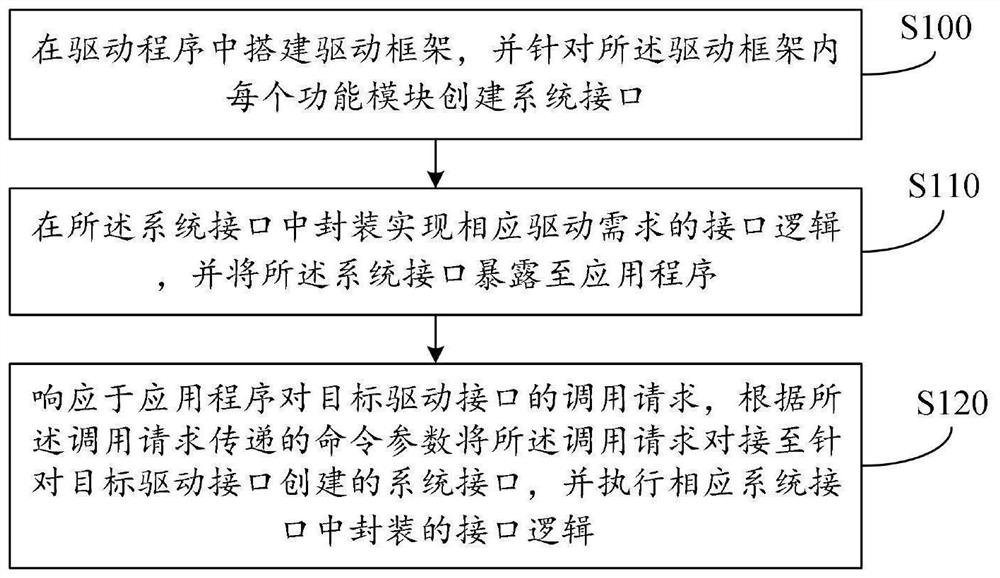

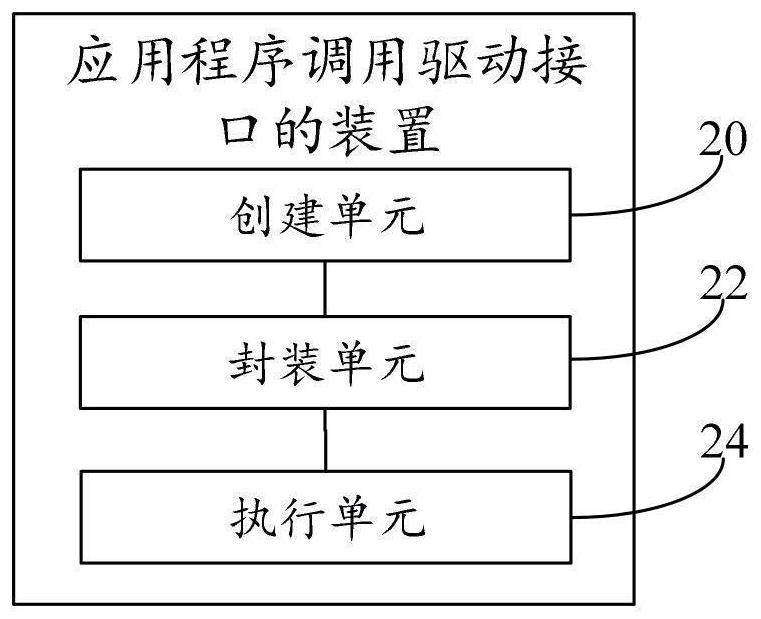

Method and device for calling driver interface by application program

PendingCN114416222AIncrease time costIncrease development costsBootstrappingExecution paradigmsSoftware engineeringApplication procedure

The invention discloses a method and device for calling a driver interface by an application program, and the method comprises the steps: building a driver framework in the driver program, and creating a system interface for each function module in the driver framework, the function modules in the driver framework correspondingly having driver interfaces for executing different driver requirements; according to the system interface packaging, interface logics with different driving requirements are achieved, and the system interface is exposed to an application program; and in response to a calling request of an application program to a target driving interface, docking the calling request to a system interface created for the target driving interface according to a command parameter transmitted by the calling request, and executing the interface logic packaged in the corresponding system interface. By means of the method, decoupling of the application program and the driving interface can be achieved, and the problem that in the prior art, due to the fact that the coupling performance between the application program and the driving interface is high, software development time and development cost are increased is solved.

Owner:JINGWEI HIRAIN (TIANJIN) RES&DEV CO LTD

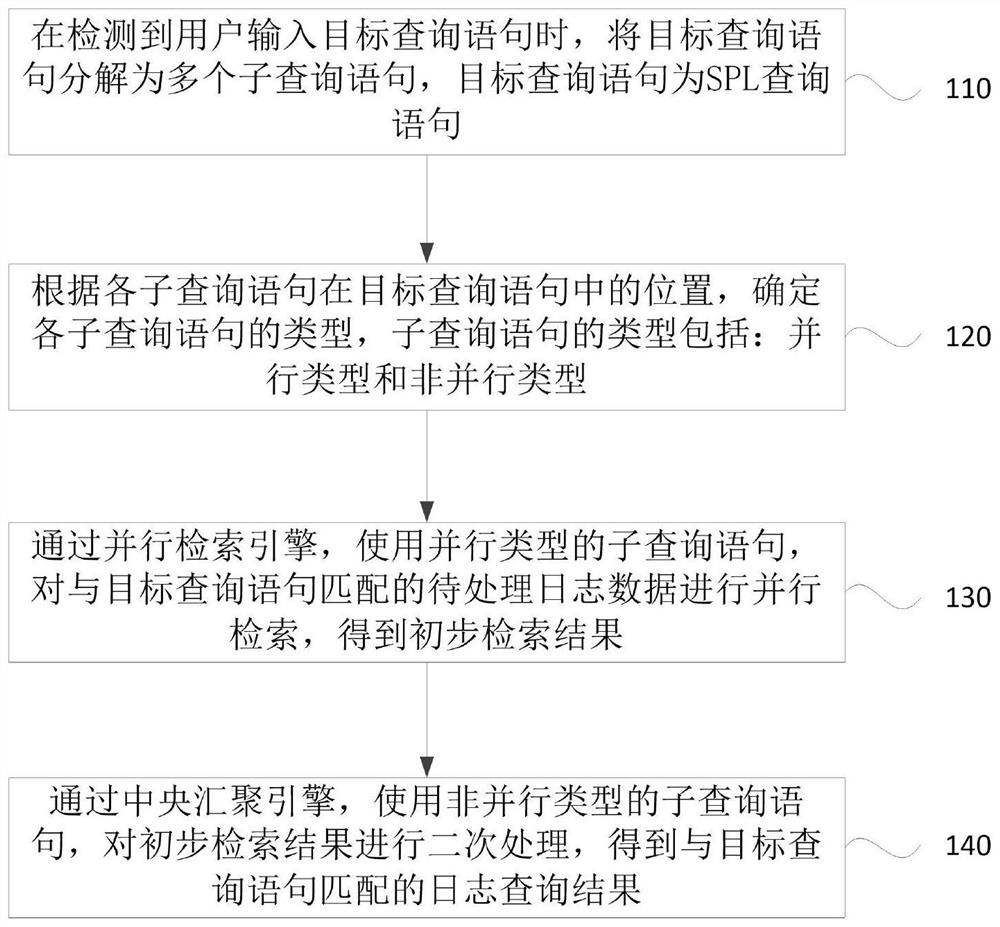

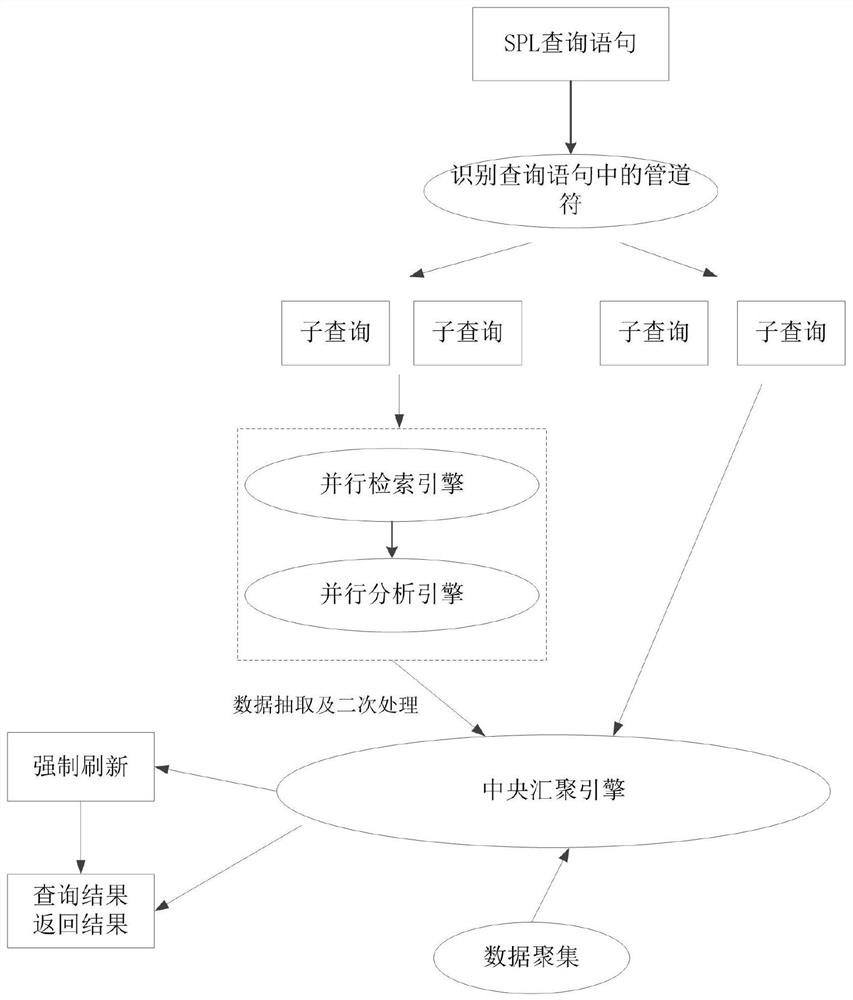

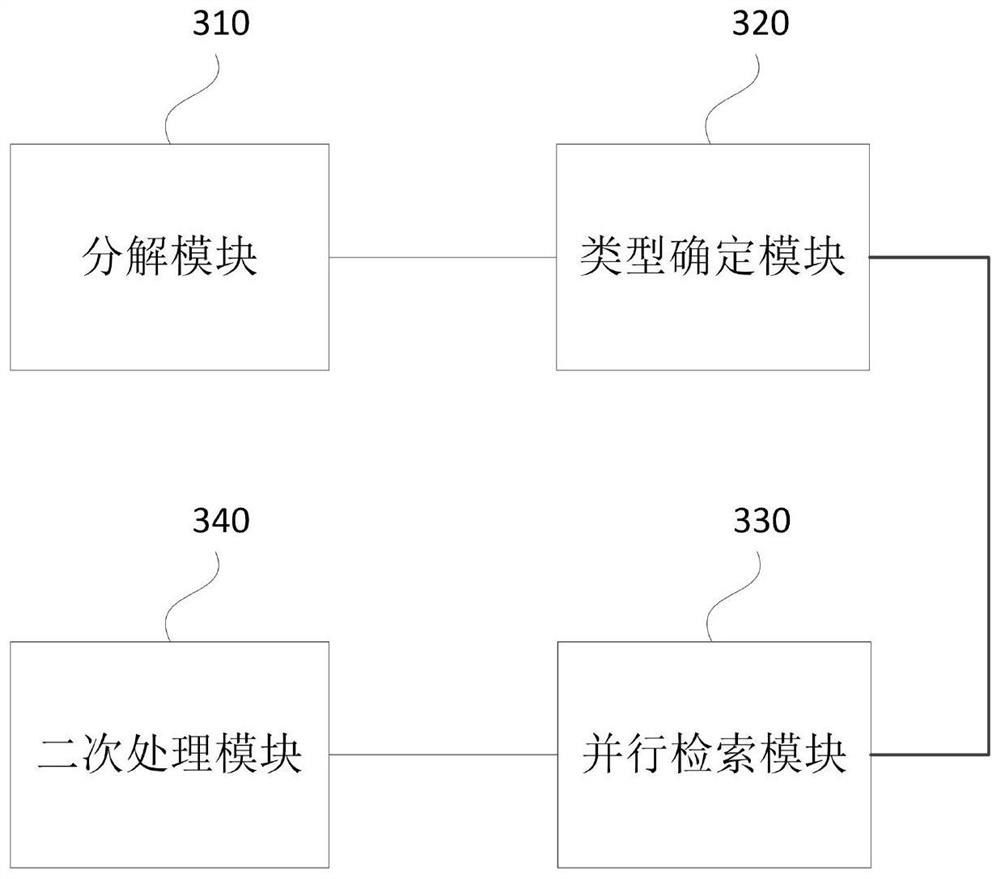

Log query method and device, equipment and storage medium

InactiveCN113360521ASolve time costQuick query analysisDigital data information retrievalSpecial data processing applicationsQuery analysisUser input

The embodiment of the invention discloses a log query method and device, equipment and a storage medium. The method comprises the following steps: when it is detected that a user inputs a target query statement, decomposing the target query statement into a plurality of sub-query statements, wherein the target query statement is an SPL query statement; according to the position of each sub-query statement in the target query statement, determining the type of each sub-query statement, wherein the types of the sub-query statements include a parallel type and a non-parallel type; performing parallel retrieval on the to-be-processed log data by using the parallel type of sub-query statements through a parallel retrieval engine to obtain a preliminary retrieval result; and performing secondary processing on the preliminary retrieval result by using non-parallel type sub-query statements through a central convergence engine to obtain a log query result matched with the target query statement. According to the technical scheme provided by the embodiment of the invention, the massive logs can be quickly queried and analyzed according to the SPL query statement without writing a complex program, and the log query result is obtained.

Owner:BEIJING YOUTEJIE INFORMATION TECH

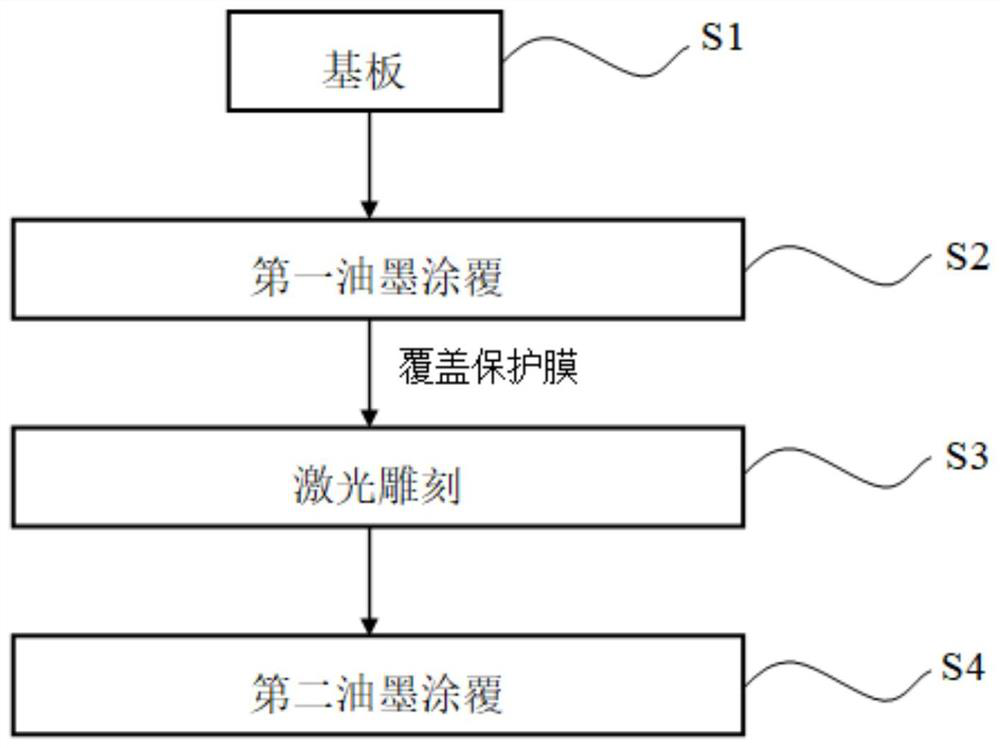

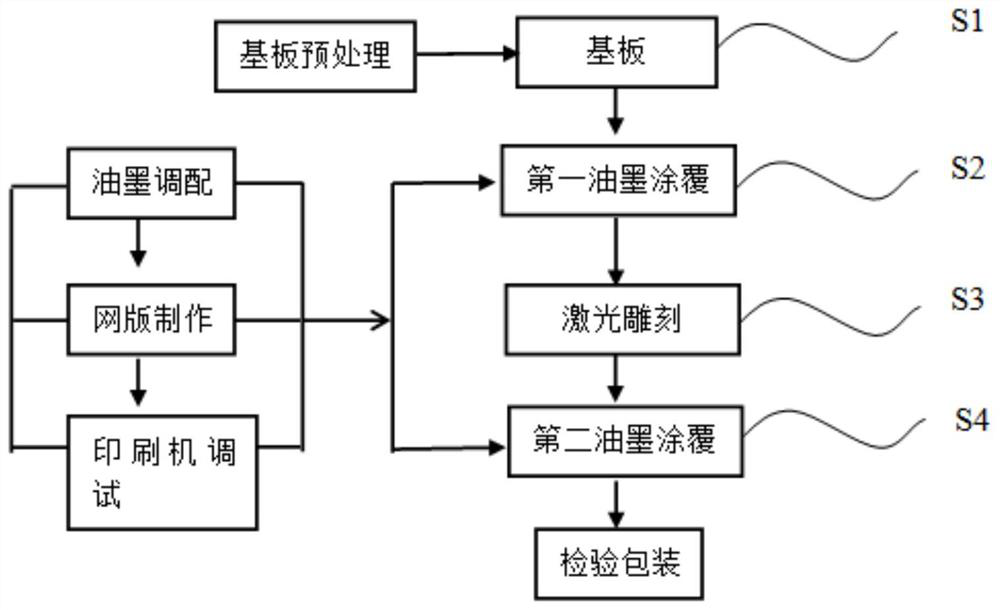

Laser engraving method

InactiveCN111731022ASmall sizeIncrease varietyDecorative surface effectsLaser beam welding apparatusLaser engravingLaser patterning

The invention provides a laser engraving method. The laser engraving method comprises the steps of coating the surface of a provided substrate with first printing ink; performing laser pattern engraving on the surface, coated with the first printing ink, of the substrate; and coating the engraved patterns of the surface of the substrate with second printing ink. By the laser engraving method, theproblem that colored patterns are difficult to obtain by performing laser engraving on the existing substrate can be solved; and meanwhile, relatively complex colored patterns can be presented on thesubstrate, thereby meeting high level of demand in the market.

Owner:安徽新彩新材料股份有限公司

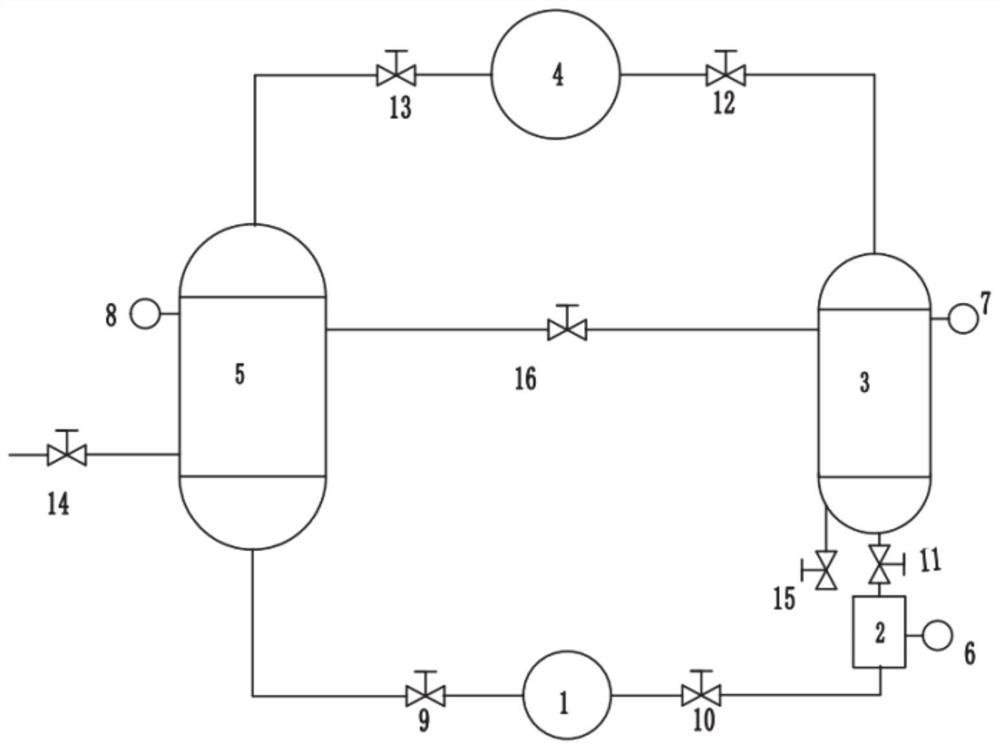

Compressor noise vibration testing system and method

ActiveCN112412769AShorten the development cycleImprove efficiencyPump testingPositive-displacement liquid enginesThermodynamicsEngineering

The invention relates to a compressor noise vibration testing system and method, and belongs to the technical field of compressors. The system comprises an air suction pressure tank and an exhaust pressure tank, and a pressure adjustment compressor and a to-be-tested compressor are connected between the air suction pressure tank and the exhaust pressure tank in parallel. The air suction pressure tank communicates with the exhaust pressure tank, a pressure balance valve is arranged between the air suction pressure tank and the exhaust pressure tank, the air suction pressure tank is connected with a refrigerant filling valve, and a stop valve is arranged on a pipeline for connecting the to-be-tested compressor with the air suction pressure tank and the exhaust pressure tank. The system is easy to operate and low in cost, noise vibration of the compressor can be rapidly tested, noise vibration effects under different design schemes are compared, the development period of the compressor isgreatly shortened, and the design cost of the compressor is reduced.

Owner:QINGDAO WANBAO COMPRESSOR

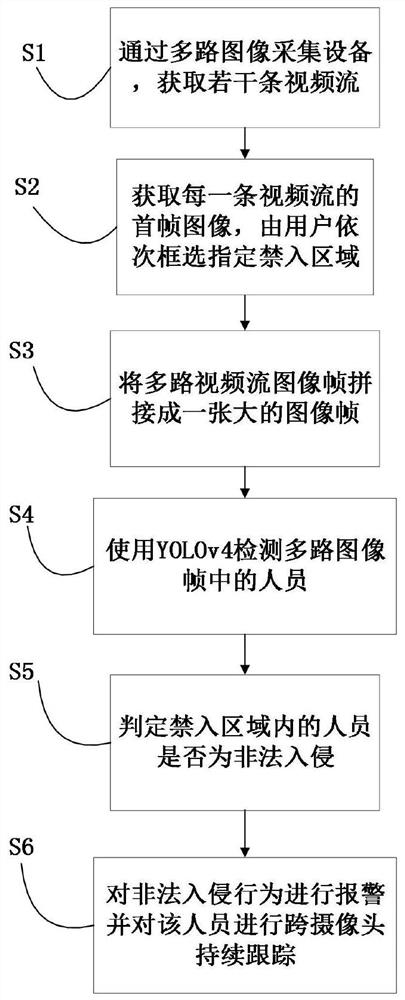

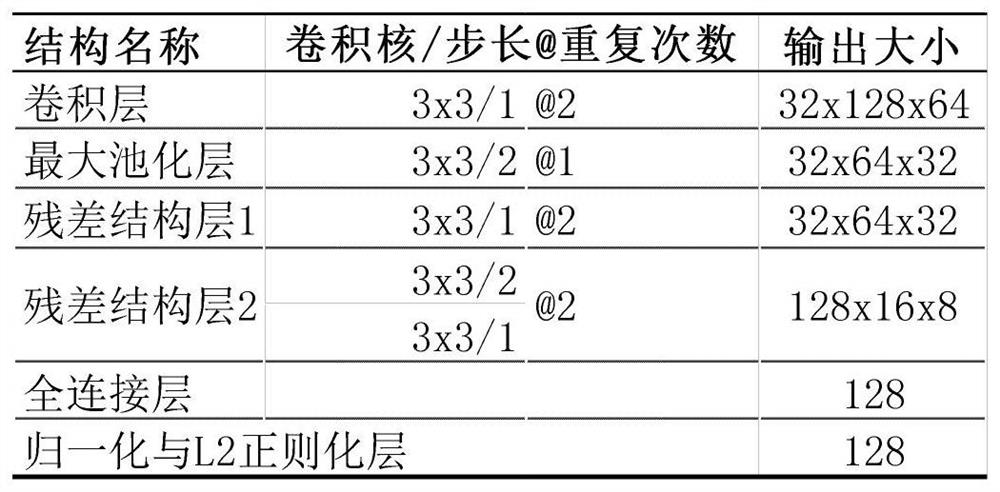

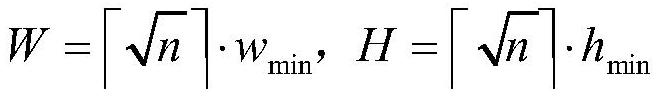

Real-time intrusion detection and tracking method for multi-channel camera

InactiveCN112257492ARealize the identification of legalitySolve the re-identification problemImage enhancementImage analysisCamera imageEngineering

The invention provides a real-time intrusion detection and tracking method for a multi-channel camera, which comprises the following steps: firstly, acquiring a plurality of video streams through multi-channel image acquisition equipment, then, acquiring a first frame image of each video stream, sequentially selecting a specified forbidden area by a user, and splicing multi-channel video stream image frames into a large image frame; then, using YOLOv4 to detect personnel in the multiple paths of image frames, judging whether the personnel in the forbidden area invade illegally or not; if the illegal invasion is found, giving an alarm for an illegal invasion behavior, and carrying out cross-camera continuous tracking on the personnel. According to the invention, through splicing multiple paths of camera pictures, the balance between time cost and computing power cost in a multi-path picture tracking task is achieved; meanwhile, multiple camera images are monitored and tracked in the same algorithm, the cross-camera tracking function can be efficiently achieved, high pertinence is achieved for forbidden zone intrusion detection and invader tracking tasks, and the accuracy is high.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

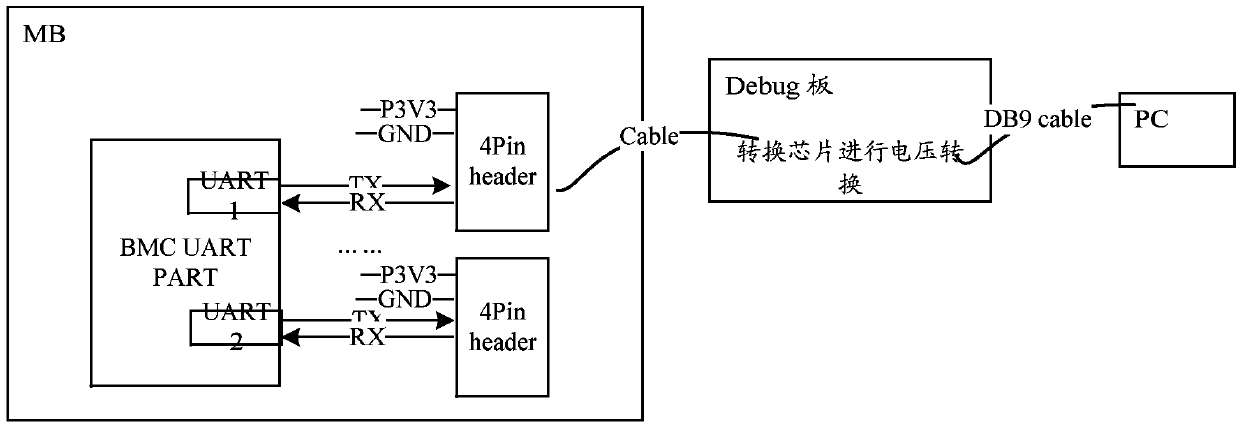

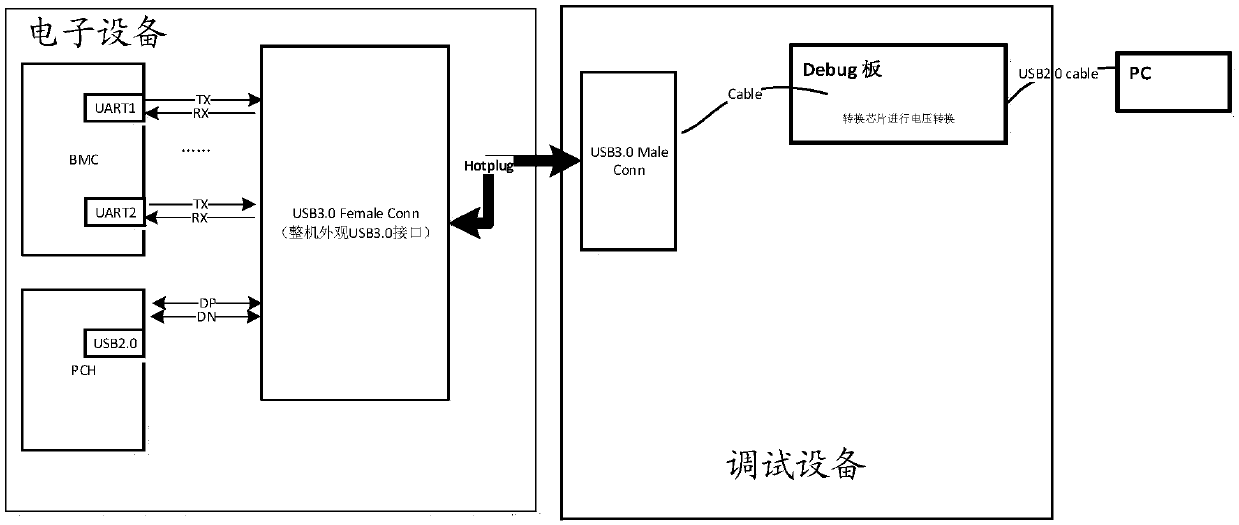

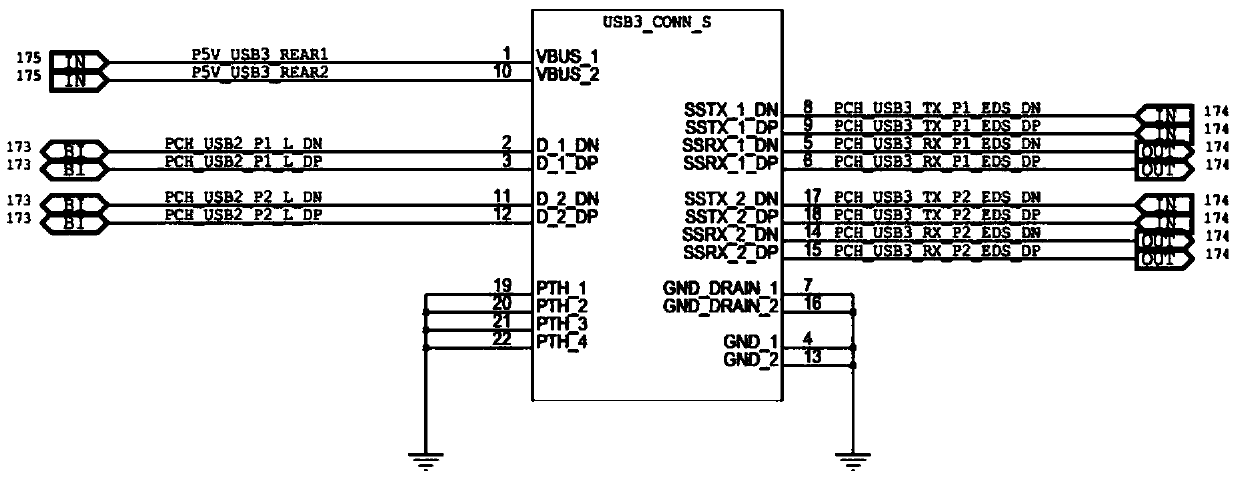

A debugging equipment and electronic equipment

InactiveCN109684216AEasy to use and convenient on-site debuggingSolve time costSoftware testing/debuggingTime costElectric equipment

The invention discloses debugging equipment and electronic equipment. The invention relates to an electronic circuit technology, and solves the problems of high time cost and maintenance cost of a disassembling debugging scheme. The debugging equipment comprises a Debug board, wherein the Debug board is connected with a male head which extends out of the debugging equipment and is matched with anexternal interface of electronic equipment to be debugged, and the male head is connected to the external interface of the electronic equipment to be debugged during debugging, so that the connectionbetween the Debug board of the debugging equipment and the electronic equipment to be debugged is completed. The technical scheme provided by the invention is suitable for debugging the electronic product after leaving the factory, and easy-to-use and convenient electronic product on-site debugging is realized.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

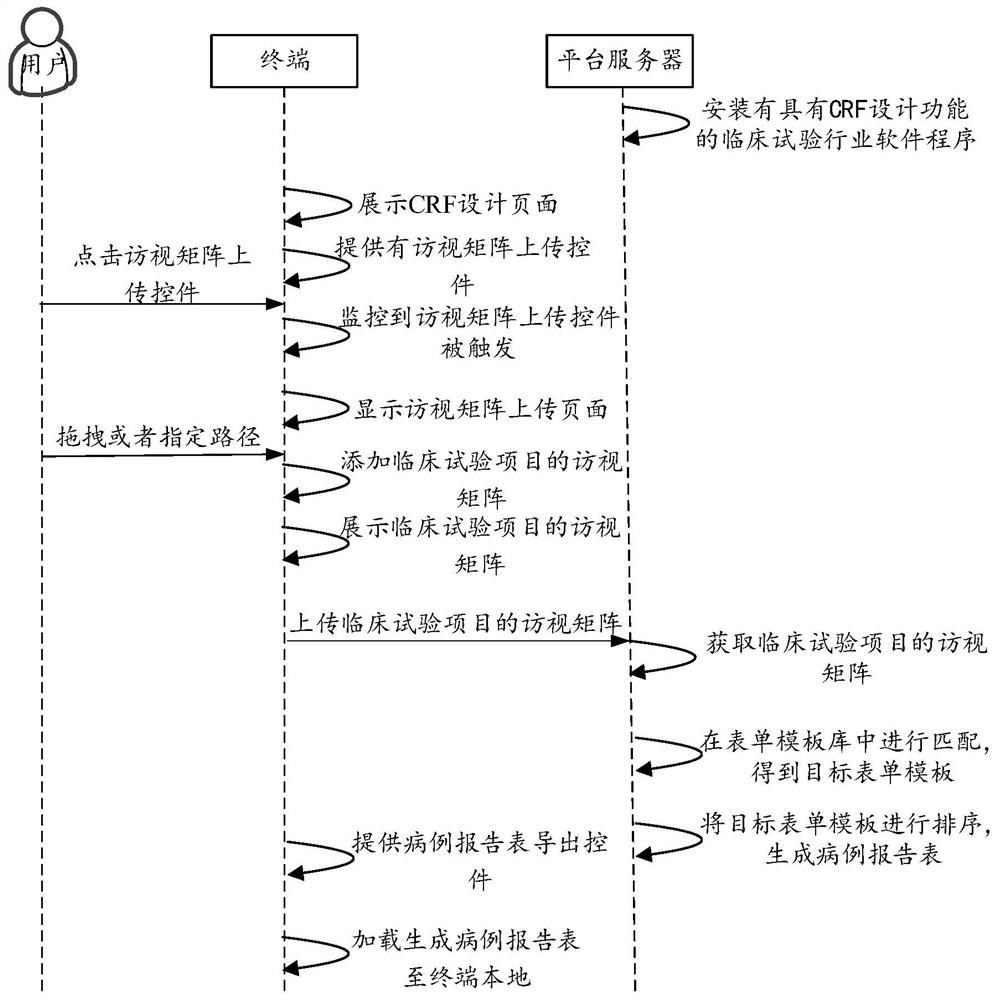

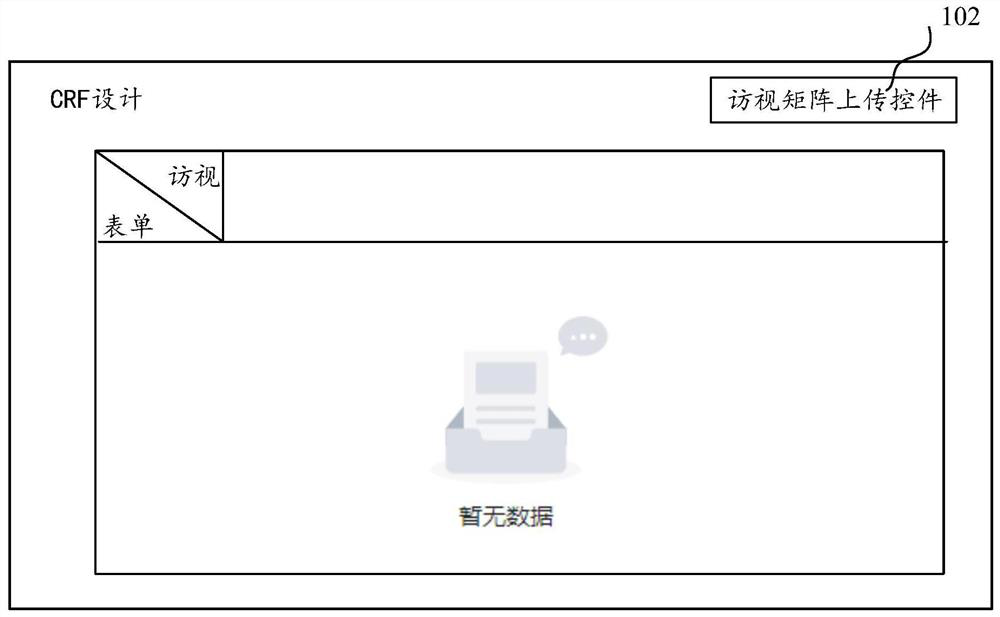

Case report form generation method and device, computer equipment and storage medium

PendingCN114005505AImprove design efficiencyReduce costs involvedText processingMedical reportsSoftware engineeringClinical tests

The invention provides a case report form generation method and device, computer equipment, a storage medium and a computer program product. The method comprises the following steps: acquiring a visit matrix of a clinical test item; matching in a form template library by using the form name in the visit matrix to obtain a target form template corresponding to the form name; and finally, sorting the target form templates based on the sequence of the visit in the visit matrix, and generating the case report form. The case report form is automatically generated based on the obtained visit matrix, the design efficiency of the case report form is improved, the related cost of the case report form is reduced, and the problem that in the prior art, a CRF design tool is used for generating CRF, and huge labor cost and time cost are consumed is solved.

Owner:浙江太美医疗科技股份有限公司

Tool for welding slab fan shape bevel frame and welding method thereof

InactiveCN106853570AAvoid deformationSave rework time and rework costWelding/cutting auxillary devicesAuxillary welding devicesRebarRepair time

The invention relates to a tooling for welding a hypotenuse frame of a slab segment and a welding method thereof, comprising two sets of welding positioning support assemblies with the same structure, including a support beam, and support legs are welded on the outside of the support beam; The inner side is provided with inclined rib plate positioning grooves consistent with the slope of the inclined rib plates on both sides of the hypotenuse frame of the slab sector, and a first tightening bolt is provided on one side of each inclined rib plate positioning groove; The inner side of the support beam between the locating grooves of the ribs is also provided with the vertical rib locating slots corresponding to the two vertical ribs in the middle of the hypotenuse frame of the slab sector, and each vertical rib locating slot is provided with There is a second jacking bolt, and a welding shrinkage compensating gasket is also equipped in the positioning groove of the above-mentioned inclined rib plate and the positioning groove of the vertical rib plate. Using the above-mentioned tooling method, the deformation caused by welding shrinkage is effectively prevented, and at the same time, the inclination of the ribs on both sides of the workpiece is ensured. It is qualified once during machining, which saves a lot of rework time and rework cost.

Owner:TIANJIN SERI MACHINERY EQUIP

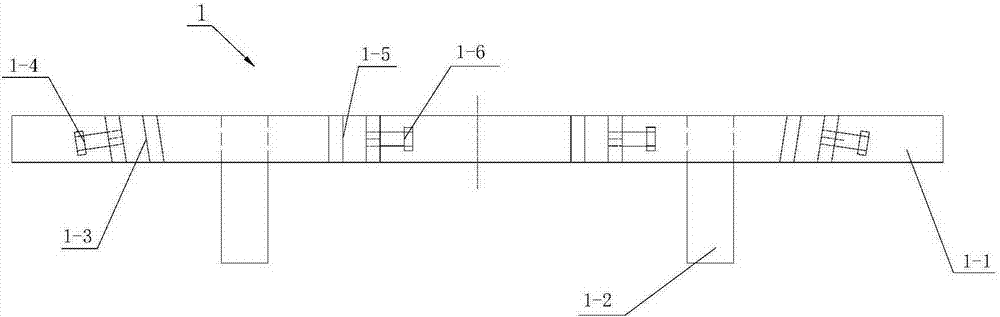

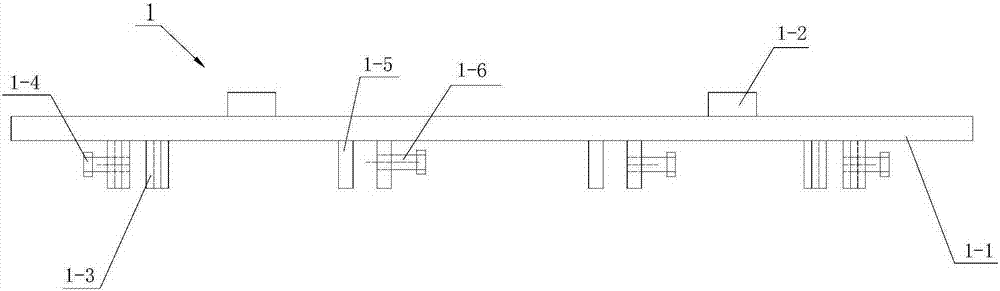

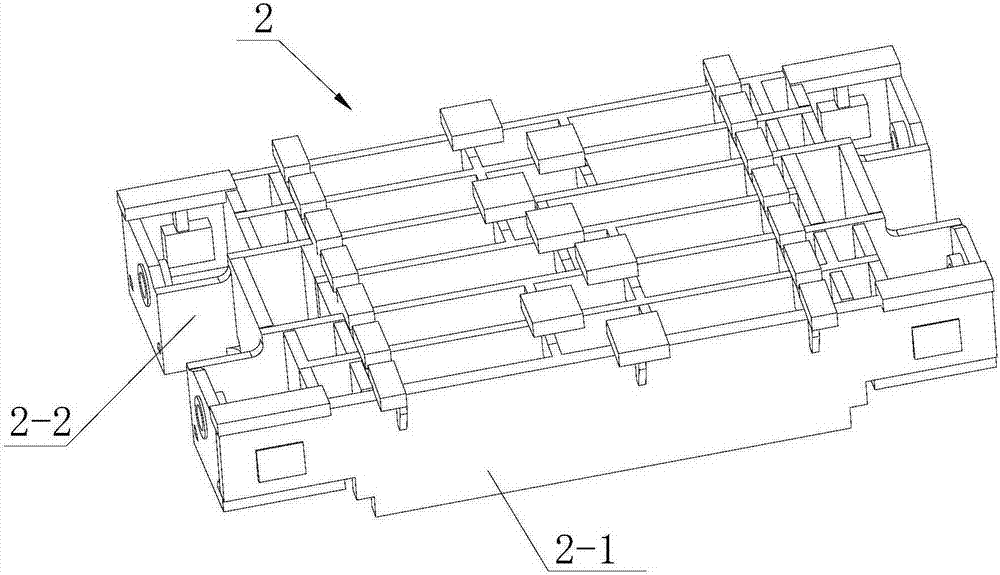

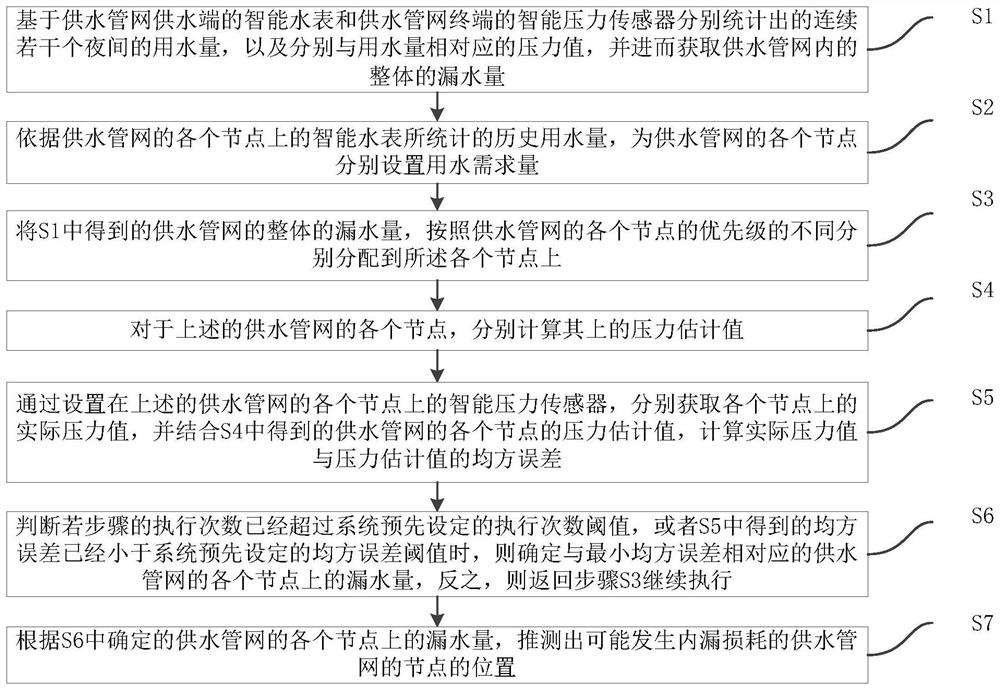

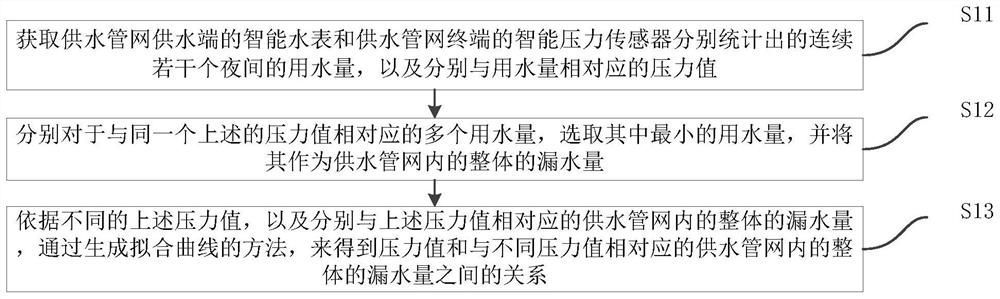

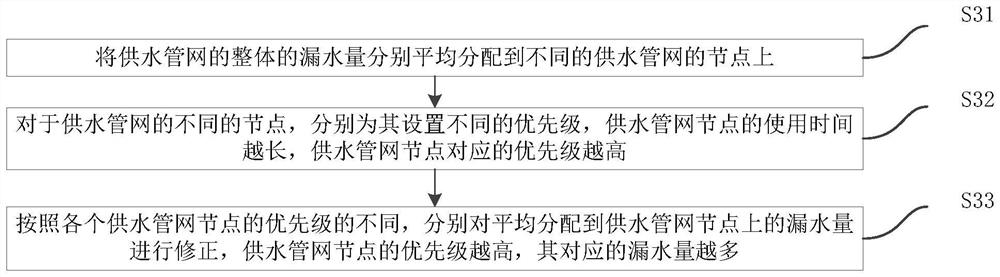

Intelligent water affair system based on wireless transmission of Internet of Things

ActiveCN114449373ASolve time costGuarantee the quality of water supplyMain station arrangementsMeasurement of fluid loss/gain rateThe InternetData acquisition

The invention belongs to the technical field of water affair management, and discloses an intelligent water affair system based on Internet of Things wireless transmission, which comprises a data acquisition layer, a data management layer and a comprehensive application layer, and is characterized in that the data acquisition layer comprises but is not limited to an intelligent water meter, an intelligent pressure sensor, an intelligent water quality detector and an intelligent liquid level sensor; the data collection layer is used for collecting water supply related data and further comprises an Internet of Things collection terminal connected with the multiple intelligent collection devices described above, and the Internet of Things collection terminal collects the water supply related data from the intelligent collection devices and transmits the water supply related data to the data management layer in a wireless communication mode; the data management layer comprises a server and is used for analyzing and processing water supply related data from the Internet of Things acquisition terminal and providing various application services for the comprehensive application layer, the comprehensive application layer comprises a computer and mobile equipment, and the water leakage node position can be speculated based on the night water consumption of the water supply network.

Owner:HENAN ZHUOZHENG ELECTRONICS TECH CO LTD

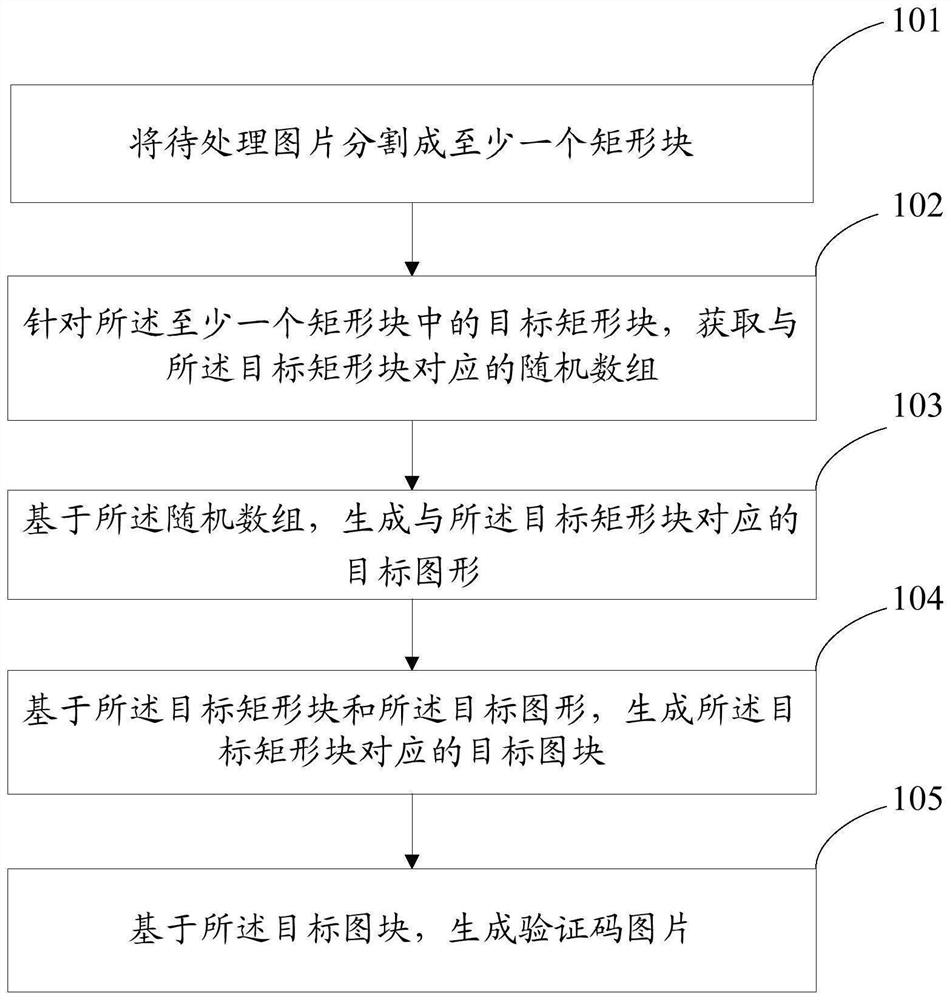

Verification code picture generation method and device, electronic equipment and storage medium

PendingCN114386011ASolve the costSolve time costDigital data authenticationEditing/combining figures or textGraphicsAlgorithm

The invention discloses a verification code picture generation method and device, electronic equipment and a storage medium, belongs to the field of data processing, and is used for solving the problem that a large amount of manpower cost and time cost need to be consumed when a large amount of verification code pictures are generated in related technologies. The method comprises the following steps: segmenting a picture to be processed into at least one rectangular block; for a target rectangular block in the at least one rectangular block, obtaining a random number group corresponding to the target rectangular block, the target rectangular block being any one of the at least one rectangular block; generating a target graph corresponding to the target rectangular block based on the random number group; based on the target rectangular block and the target graph, generating a target graph block corresponding to the target rectangular block; and generating a verification code picture based on the target image block.

Owner:BEIJING YUNCE INFORMATION TECH CO LTD

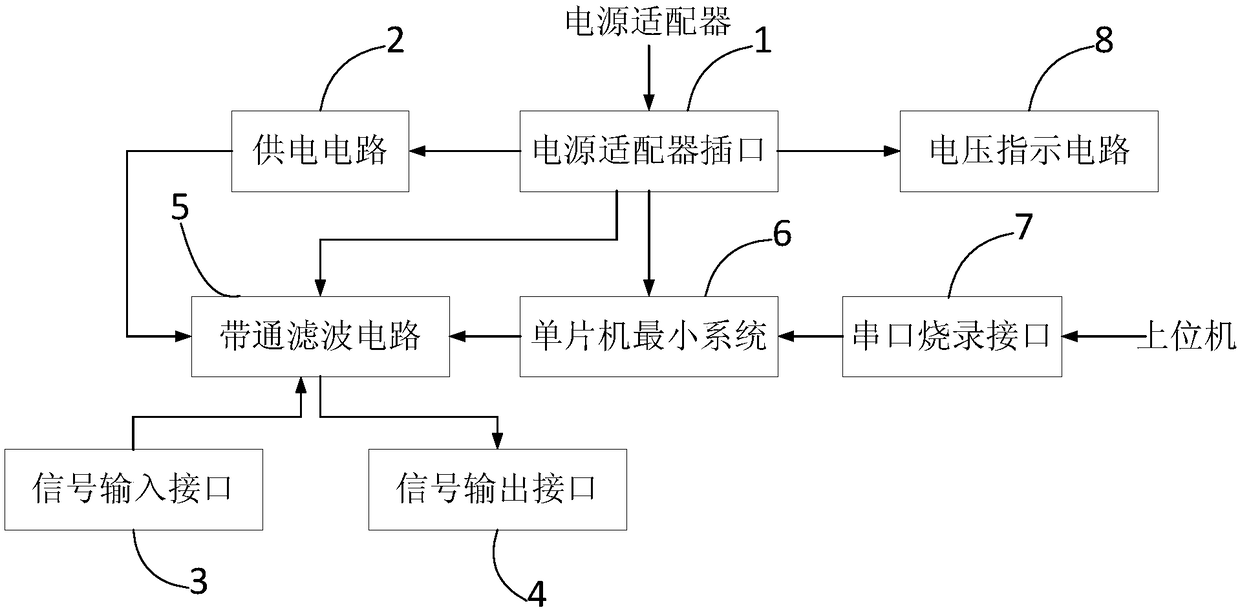

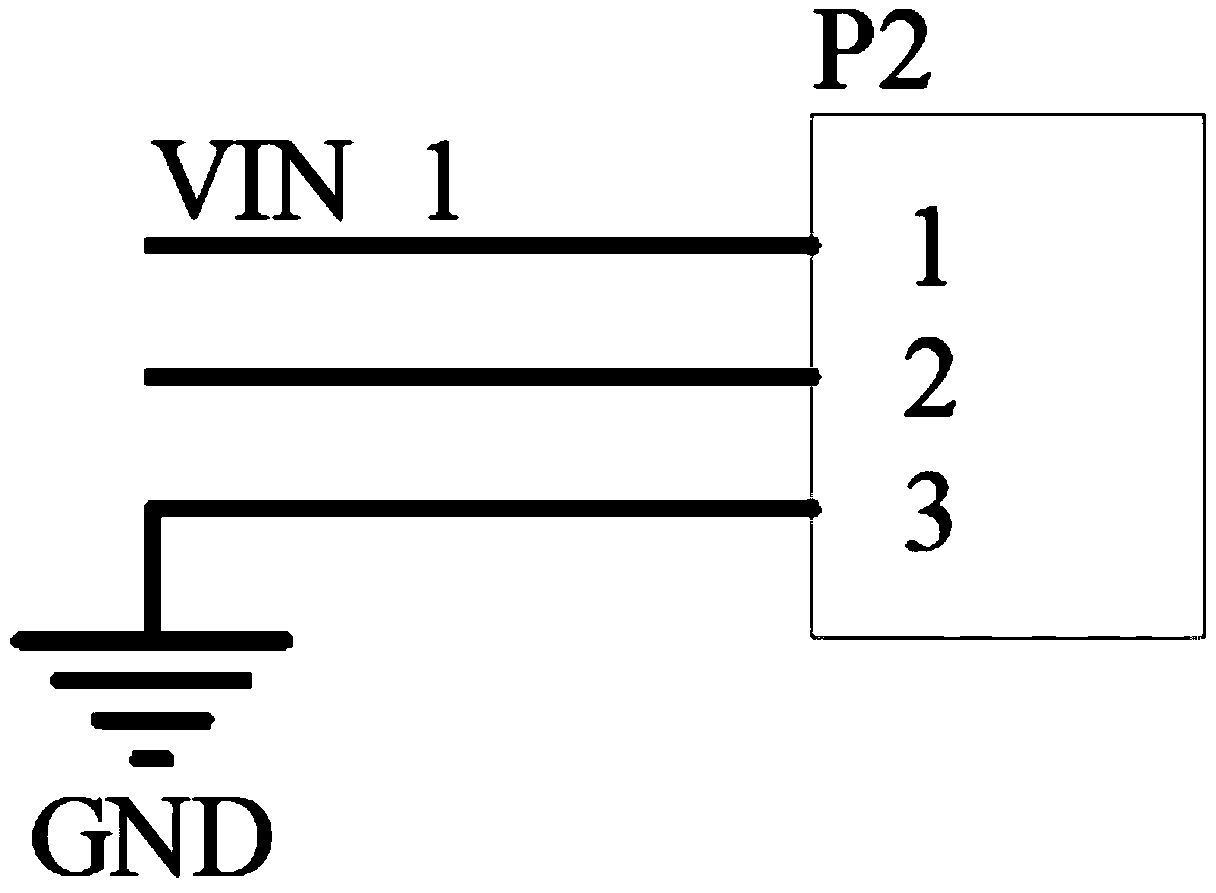

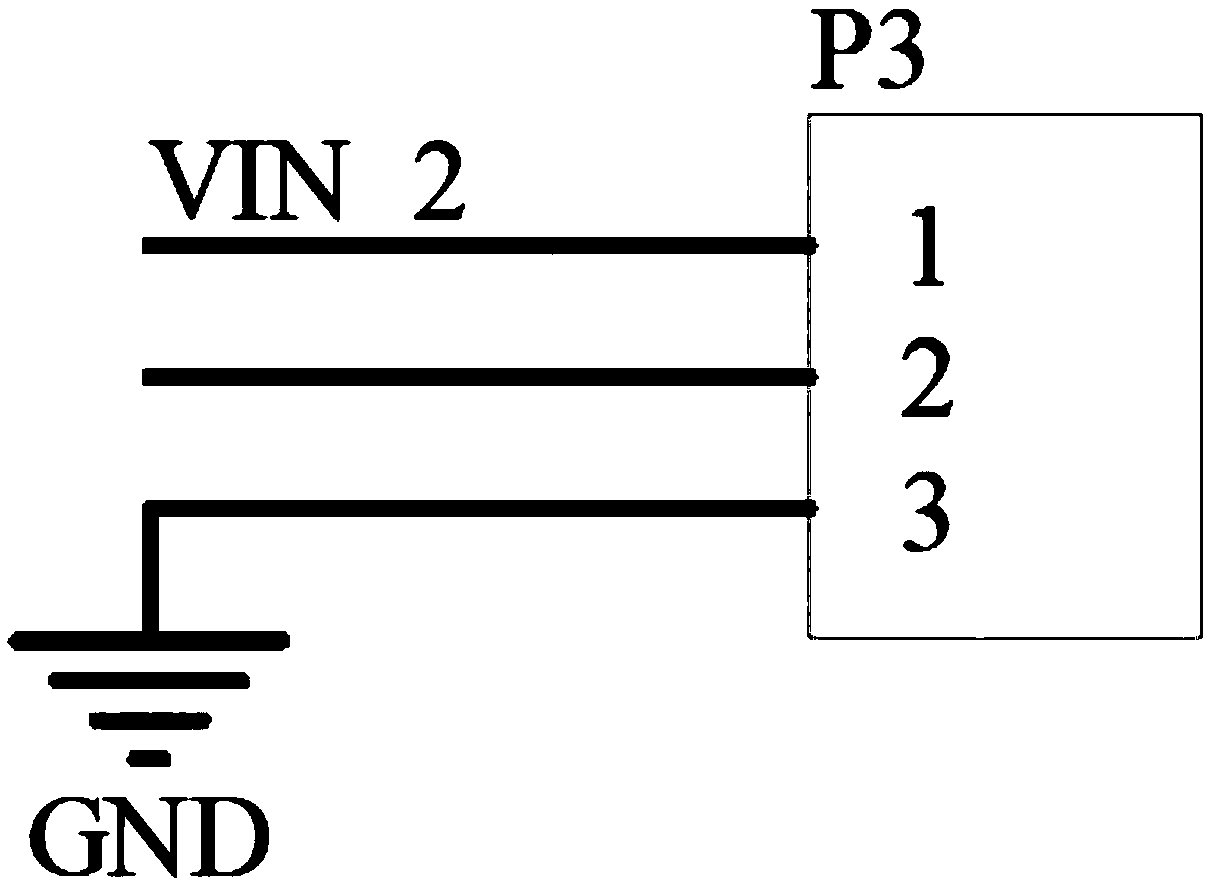

Two-channel center-frequency-adjustable band-pass filter

InactiveCN108900176ASolve the inaccurate center frequencySolve time costOne-way transmission networksBandpass filteringMicrocontroller

The invention belongs to the technical field of circuit design, and relates to a two-channel center-frequency-adjustable band-pass filter. The two-channel center-frequency-adjustable band-pass filtercomprises a signal input interface, a signal output interface, a band-pass filter circuit, a single chip microcomputer minimal system and a serial port burning interface and is characterized in that the input end of the band-pass filter circuit obtains input signals through the signal input interface; the output end outputs the filtered signals through the signal output interface; the single chipmicrocomputer minimal system is connected with the serial port burning interface and obtains the complied program through the serial port burning interface; the clock frequency input port of the band-pass filter circuit is connected with the clock frequency output port of the single chip microcomputer minimal system; different clock frequency is obtained. The clock frequency is output through thesingle chip microcomputer minimal so as to control the center frequency of the band-pass filter; the center frequency of the band-pass filter module can be fast regulated; the precision is high; the filtering effect is good and stable.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

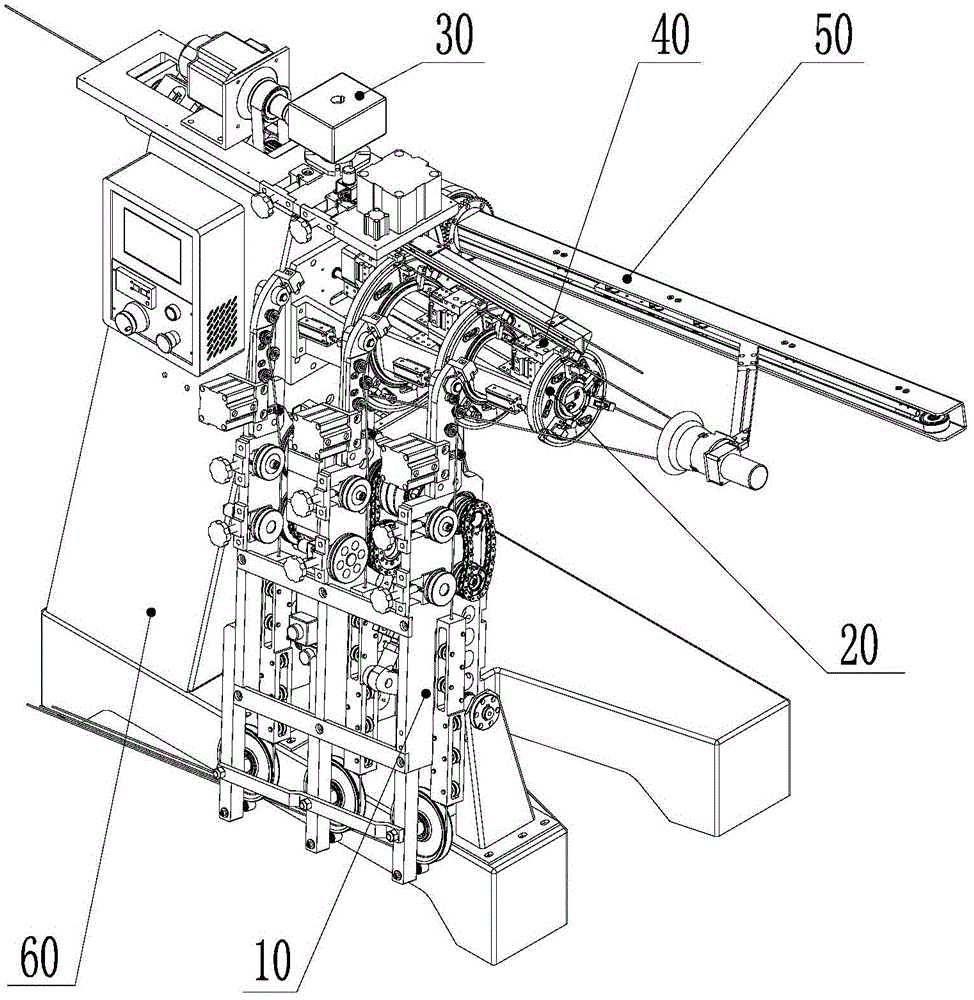

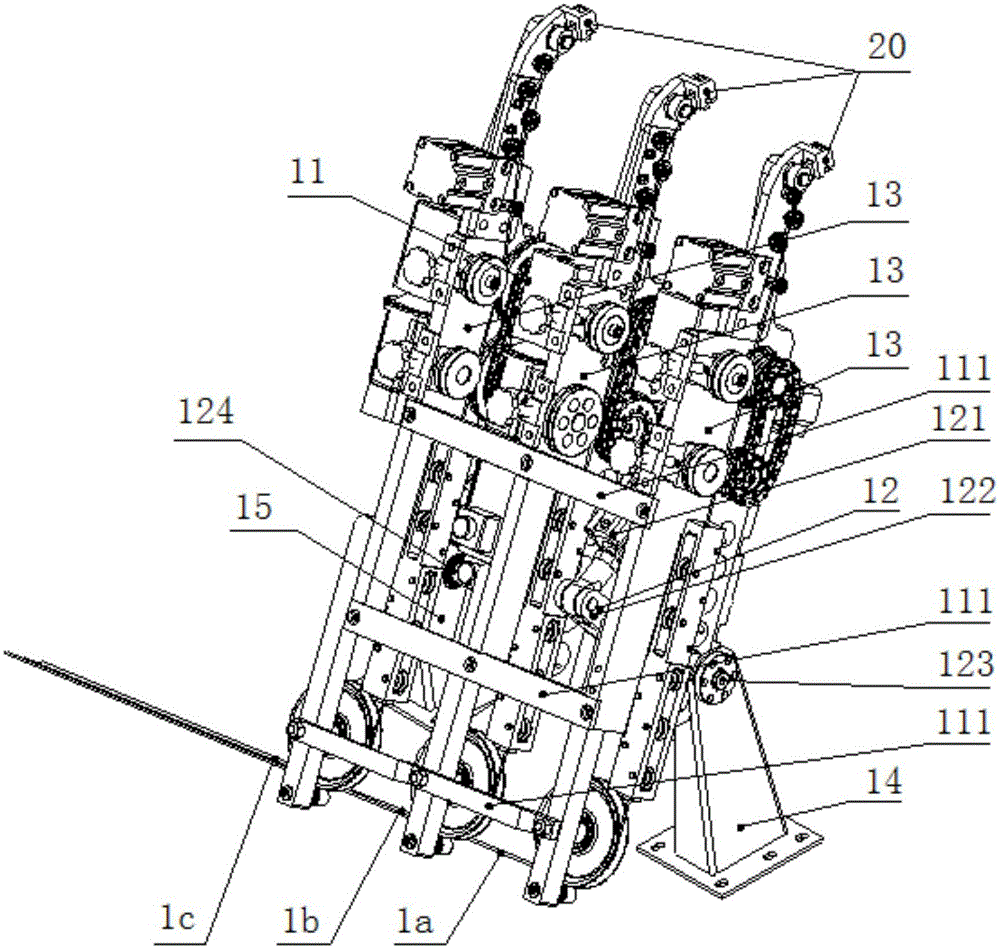

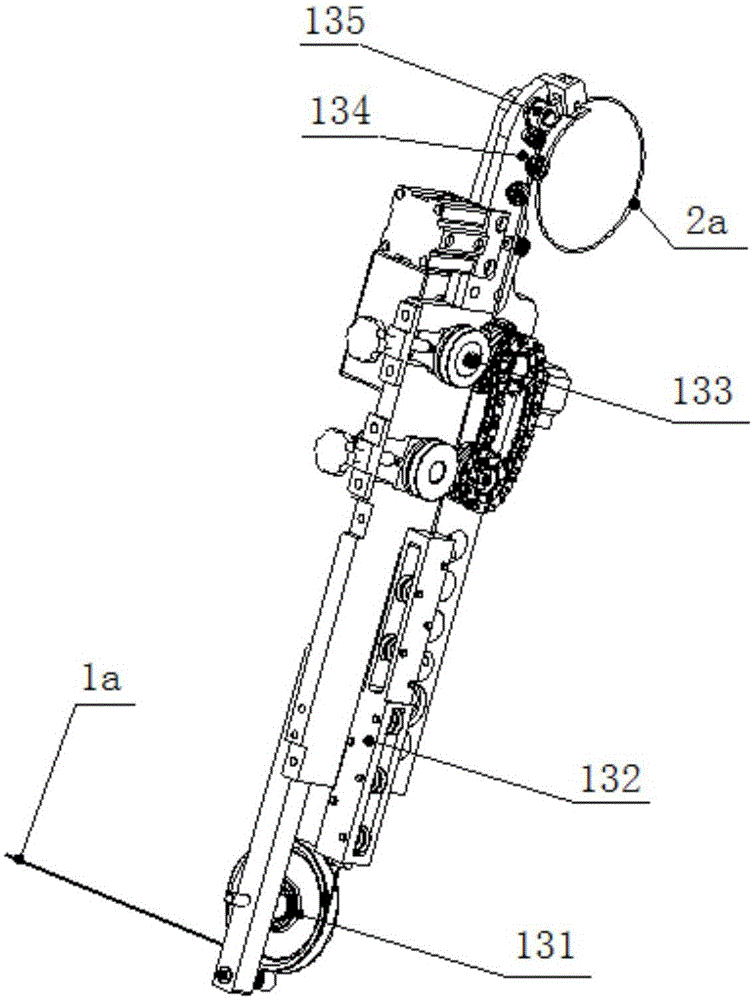

Automatic forming machine for plant growth support

InactiveCN106256459ASolve time costHigh degree of automationWire networkWire ringsGrowth plantEngineering

The invention relates to an automatic forming machine for a plant growth support. The automatic forming machine comprises a wire rolling system, a mould system and a welding system which are arranged on a rack. The wire rolling system is used for simultaneously rolling multiple metal wires into rings, the mould system is used for carrying all the rings and driving all the rings to synchronously rotate by a preset angle, every time the rings rotate, the welding system welds a straight wire to all the rings, and after all the welding producers are completed in rotating, the plant growth support is formed. The automatic forming machine solves the problems that in the prior art, multiple devices are needed to complete round rolling, wire straightening and welding, and the time cost and the labor cost are high, and the automatic forming machine is high in automation degree and capable of reducing the time cost and the labor cost of production.

Owner:丑毅 +1

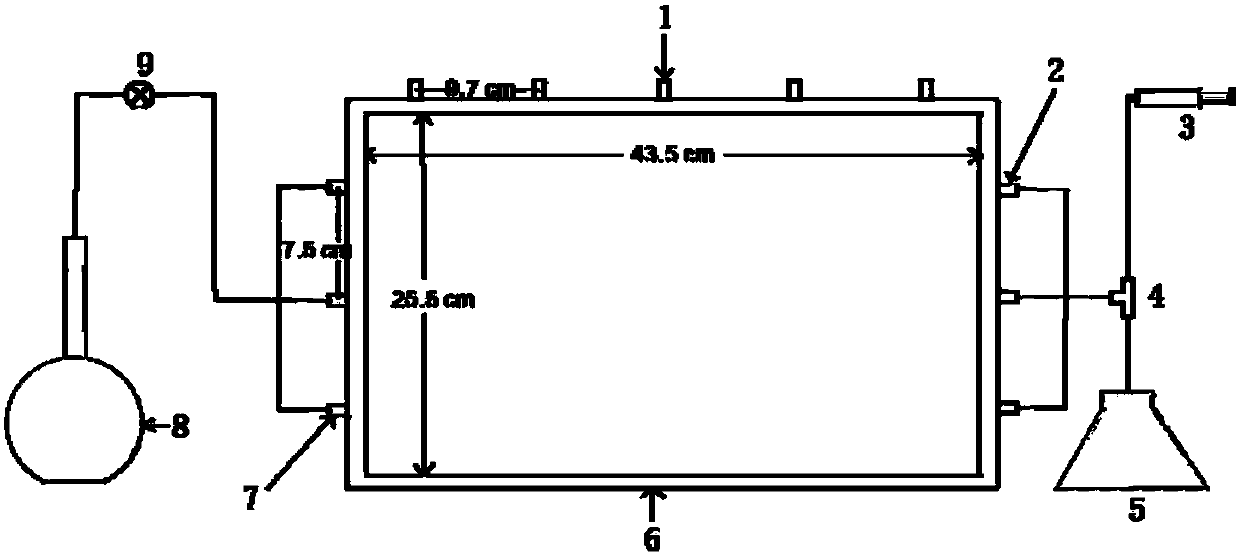

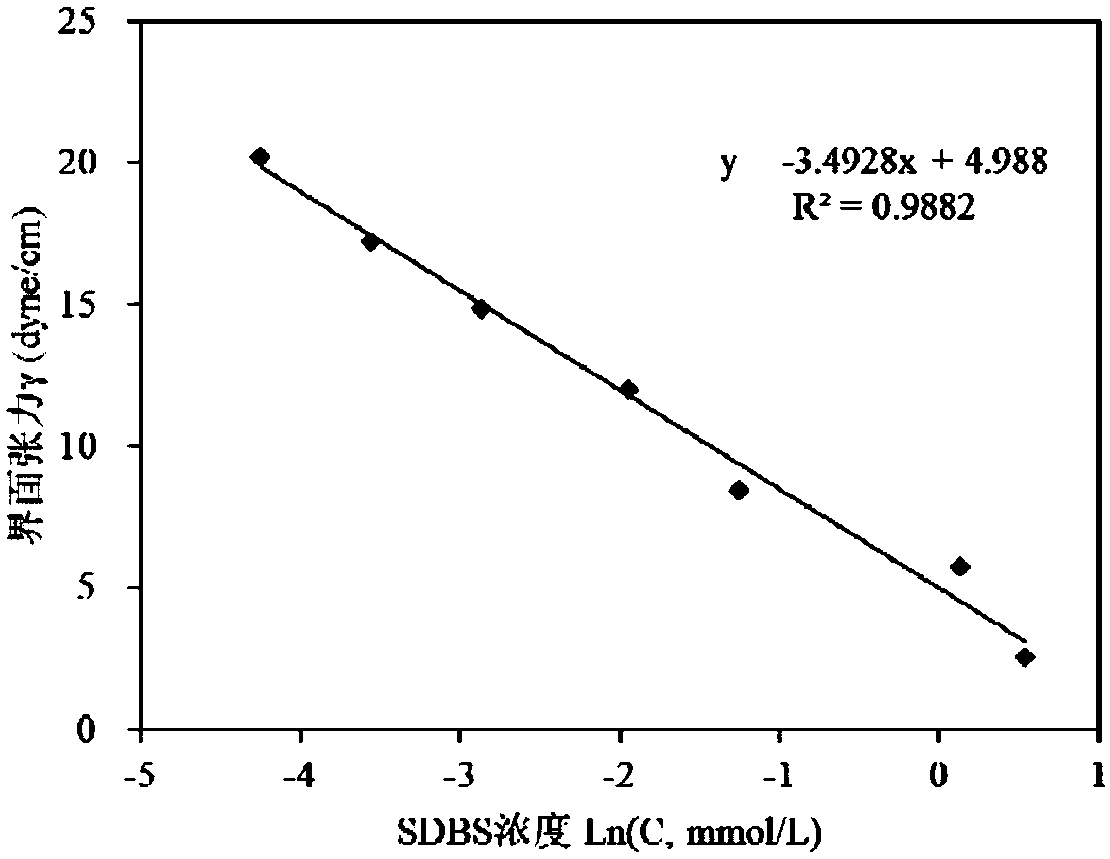

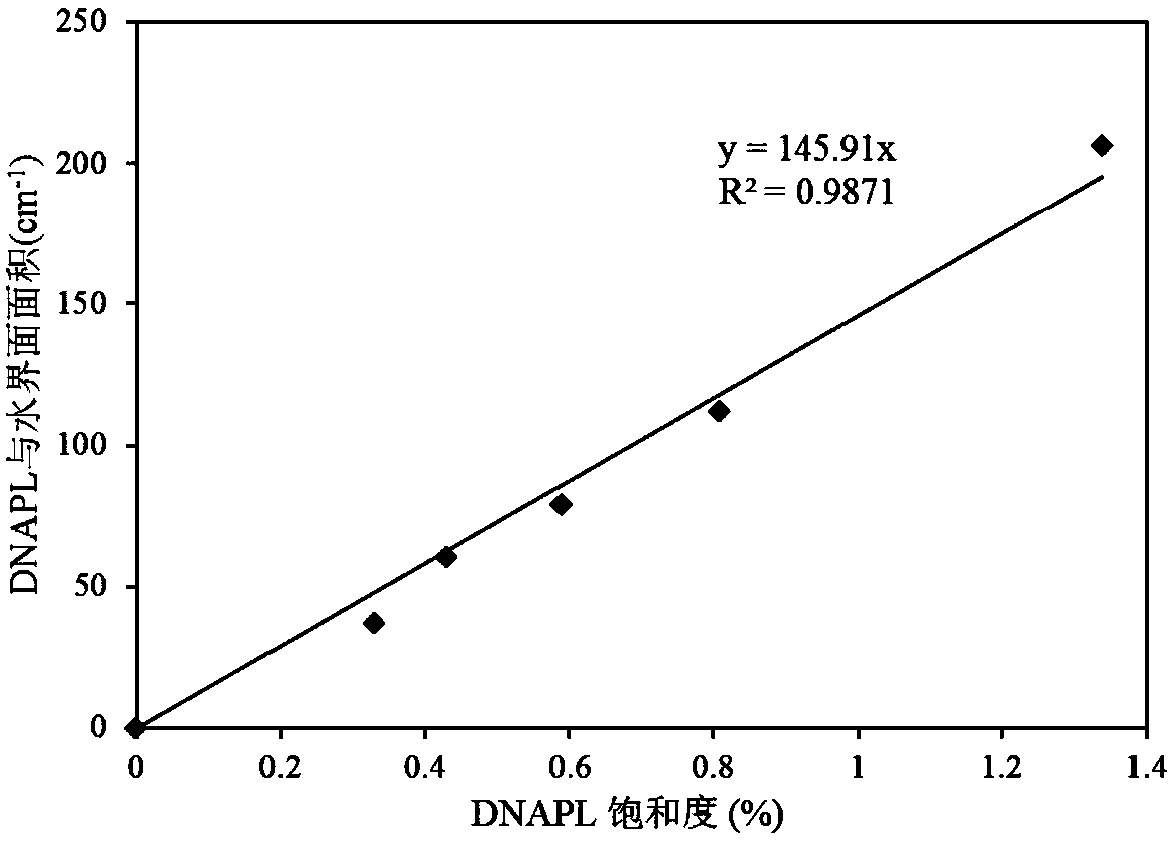

A kind of dnapl and aqueous phase interfacial area determination method

ActiveCN105842123BSimple methodEasy to operateSurface/boundary effectDecision makerDense non-aqueous phase liquid

Owner:BEIJING NORMAL UNIVERSITY

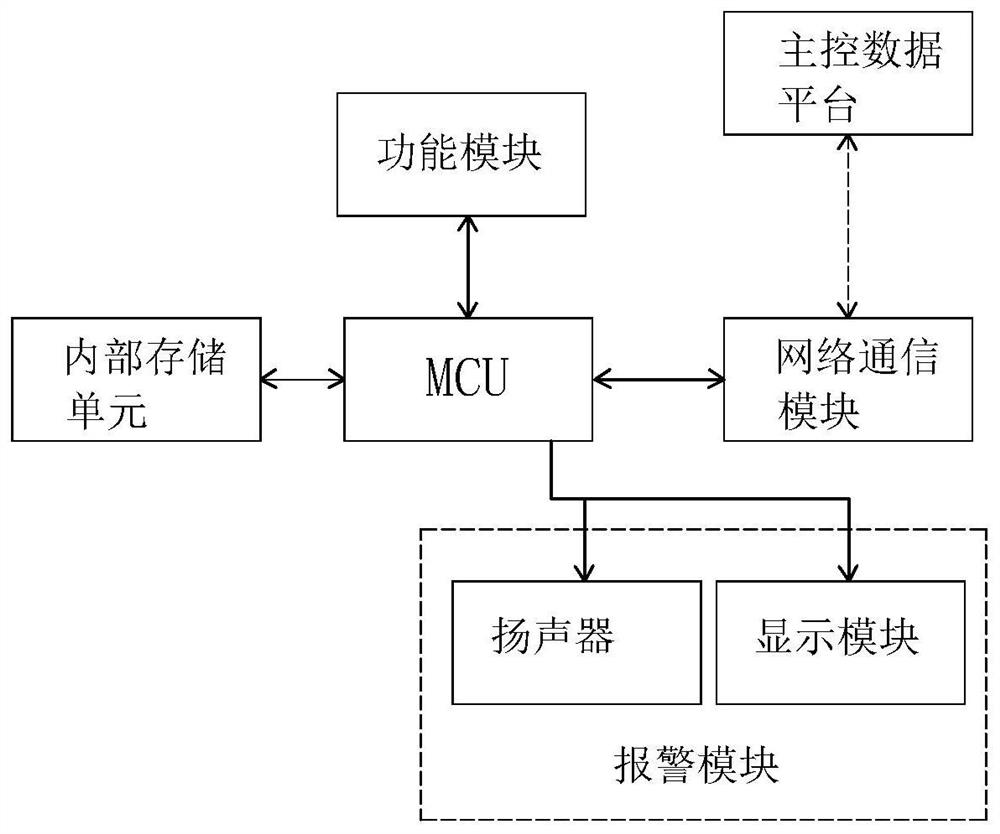

Television capable of intelligently detecting and reporting errors

PendingCN112752092ASolve the problem of time and labor costSolve time costTelevision systemsEmbedded systemTroubleshooting

The invention discloses a television capable of intelligently detecting and reporting errors, and the television comprises a function module serving as a to-be-detected fault module; an MCU which scans the working state of the functional module through a bus protocol or a port function; an internal storage unit which is connected with the MCU so as to store the classification and coding information of the functional modules and the working states; a fault diagnosis unit which is used for reading the classification and coding information of the functional modules and the working states and identifying the fault information of the functional modules; a network communication module which is used for transmitting fault information of the function module; and a main control data platform which is used for collecting and counting fault information of the functional module. According to the scheme, the MCU scans the working state of the functional module through a bus protocol or a port function, classifies and codes the functional module and the working state, stores the functional module and the working state in the internal storage unit, and reports the functional module and the working state to a background master control data platform after the functional module and the working state are recognized by the fault diagnosis unit, so the problems of time and labor cost of manual troubleshooting can be solved.

Owner:GUANGDONG CHANGHONG ELECTRONICS

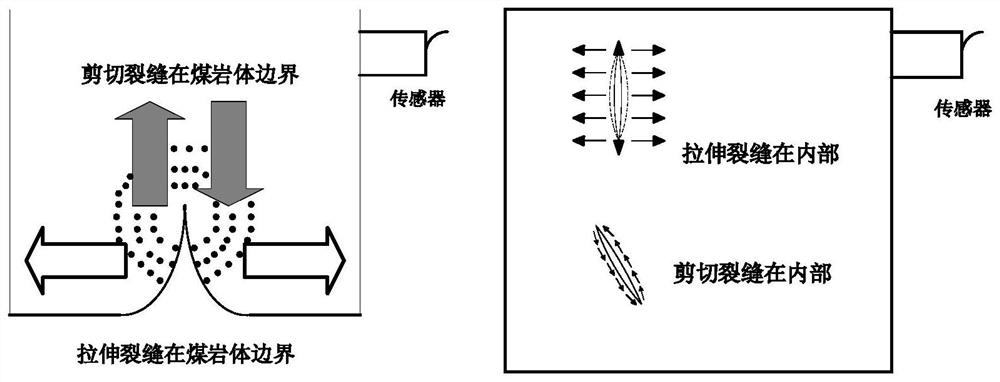

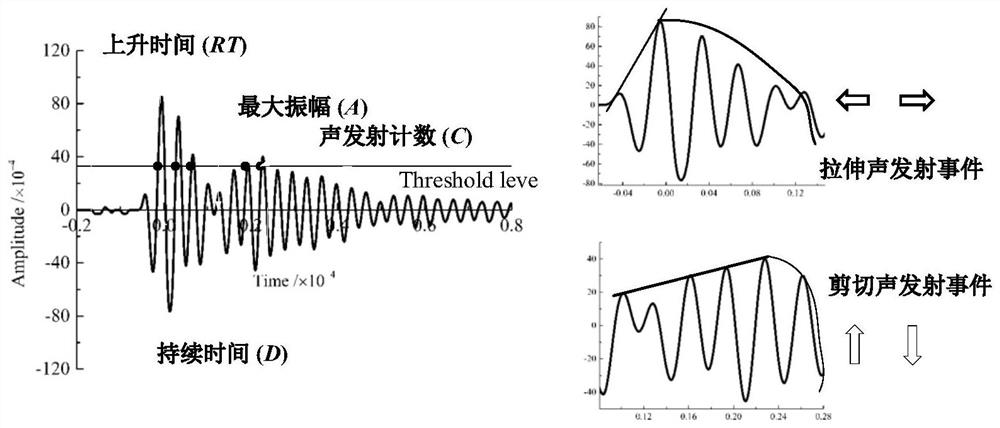

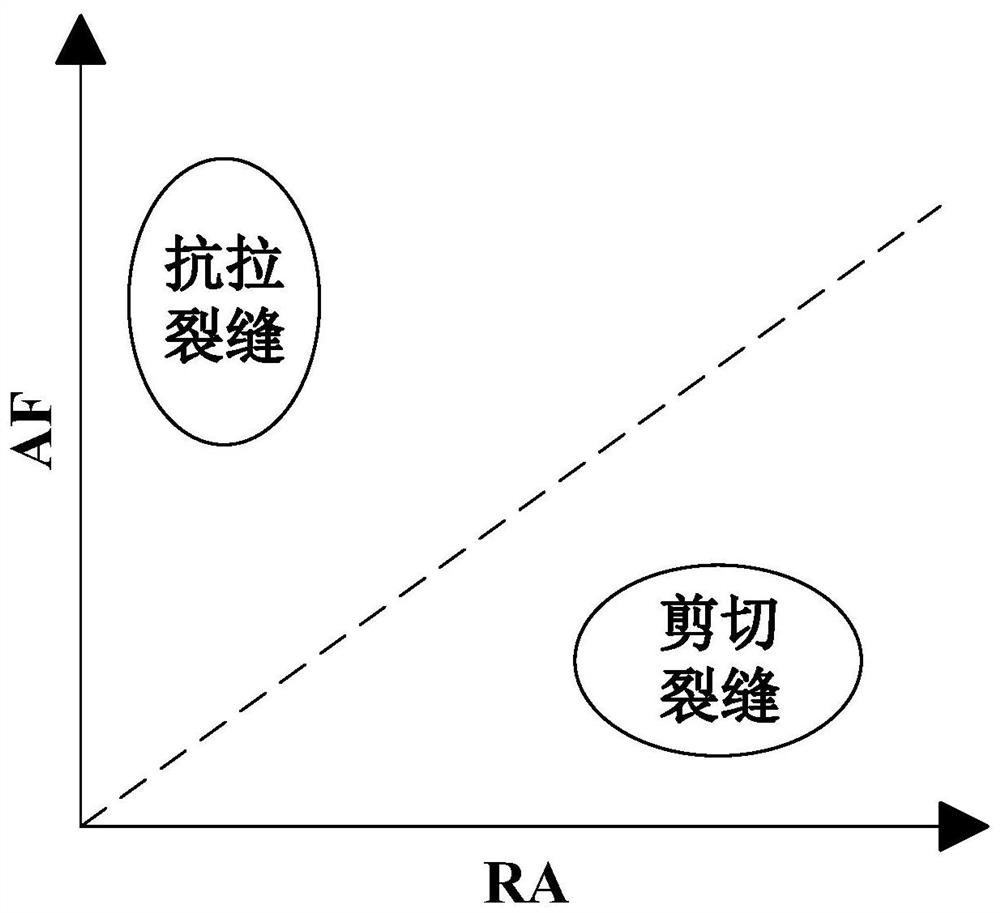

Acoustic emission signal visualization processing method for rock fracture classification

ActiveCN113358469AAddressing Inconvenience and High CostsImportant scientific significance and engineering valueAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesData pointVisualization

The invention relates to an acoustic emission signal visualization processing method for rock fracture classification. Intelligent operation is realized through a series of steps of acoustic emission data acquisition, collection, model training, error analysis and verification, and the whole model can adapt to visualization identification of multiple fracture modes in the mining engineering field and the rock engineering field. The applied visualization processing method is key density function estimation, and compared with other functions, the method can more accurately describe probability distribution of unknown acoustic emission events. And the key density function estimation is a dimensionless function method, the operation is more convenient, the method is not sensitive to the data volume, and for a large number of acoustic emission data points, the operation can be completed in several seconds each time.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com