Nonaqueous phase oil product deep desulfurizing device and desulfurizing process

A desulfurization device and a technology for deep desulfurization, which are applied in the petroleum industry, processing hydrocarbon oil, refining with oxygenated compounds, etc., can solve the problem of increasing the reaction operation time and operation cost, reducing the contact area and mass transfer rate between phases, and a three-phase system. Mixing effect limitation and other problems, to increase the interphase contact area and mass transfer rate, solve the operation time and operation cost, and achieve the effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] The preparation of embodiment 1 catalyst

[0110] The NaY molecular sieve was activated under an air atmosphere at 500° C. for 4 hours to remove impurities and carbon deposits in the molecular sieve to obtain an activated NaY molecular sieve.

[0111] At 90°C, N 2 Atmosphere, 0.1mol / L CoCl 2 The solution and the activated NaY molecular sieve were fully stirred and refluxed for 24 hours according to the solid-liquid ratio of 1:10, filtered and the filter cake was washed several times with distilled water until there were no chloride ions in the filtrate, and the filter cake was vacuum-dried at 110°C for 12 hours to obtain a light pink CoY molecular sieve .

[0112] Under normal temperature and pressure, salicylaldehyde and ethylenediamine react at a molar ratio of 2:1, salicylaldehyde is dissolved in ethanol and added to the three-hole flask, and ethylenediamine dissolved in ethanol solution is added to the three-necked flask in a dropwise manner , a large number of y...

Embodiment 2

[0114] Embodiment 2 desulfurization treatment

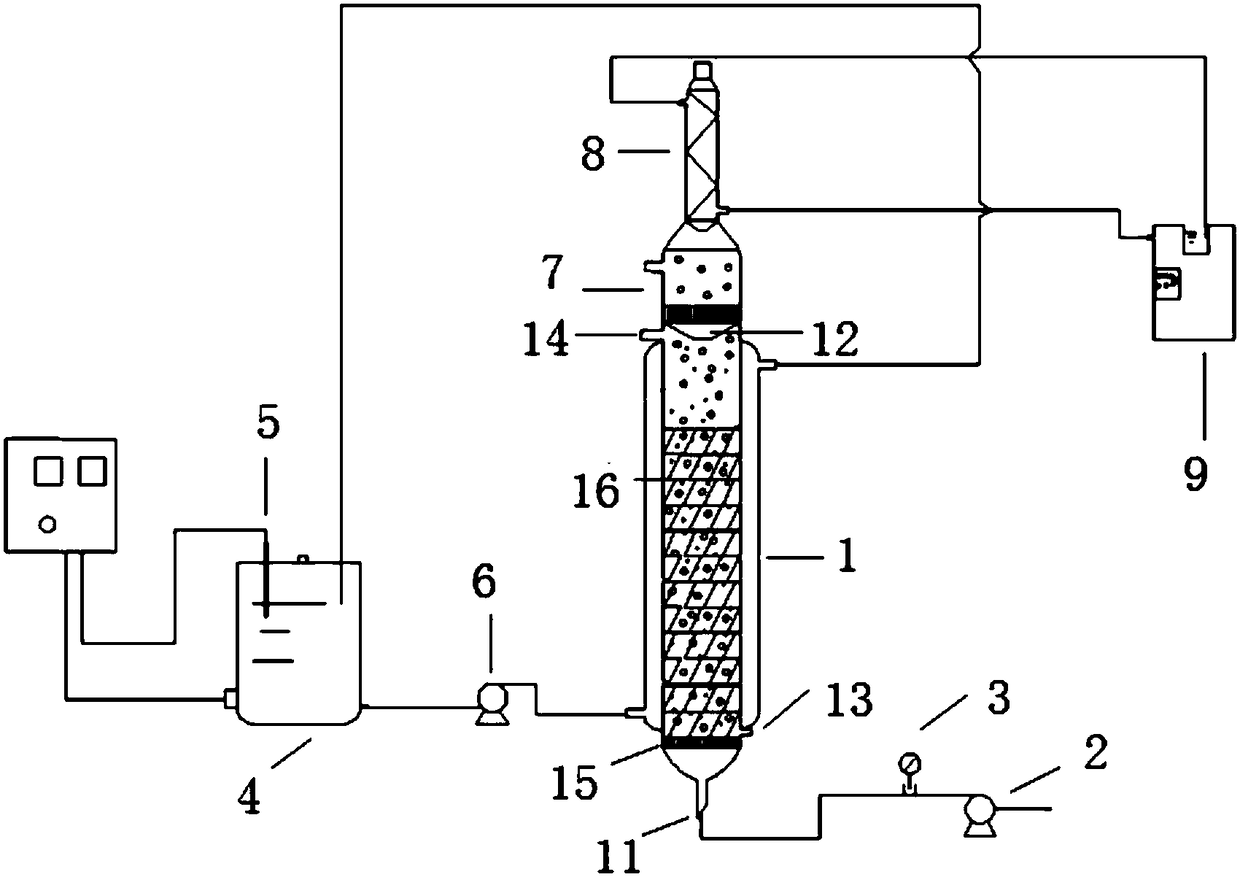

[0115] Deep desulfurization device is used for oil desulfurization, desulfurization device such as figure 1 shown.

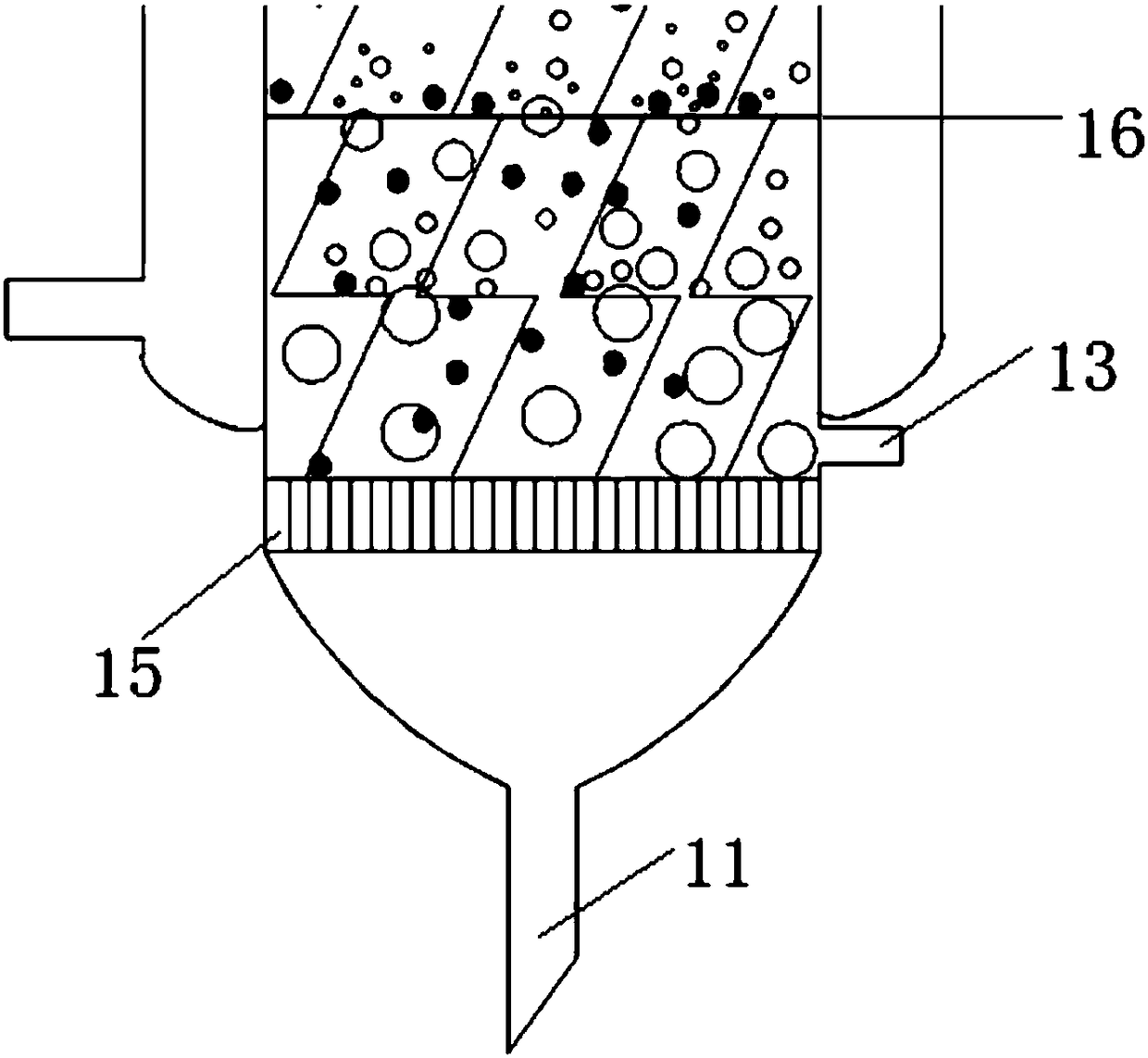

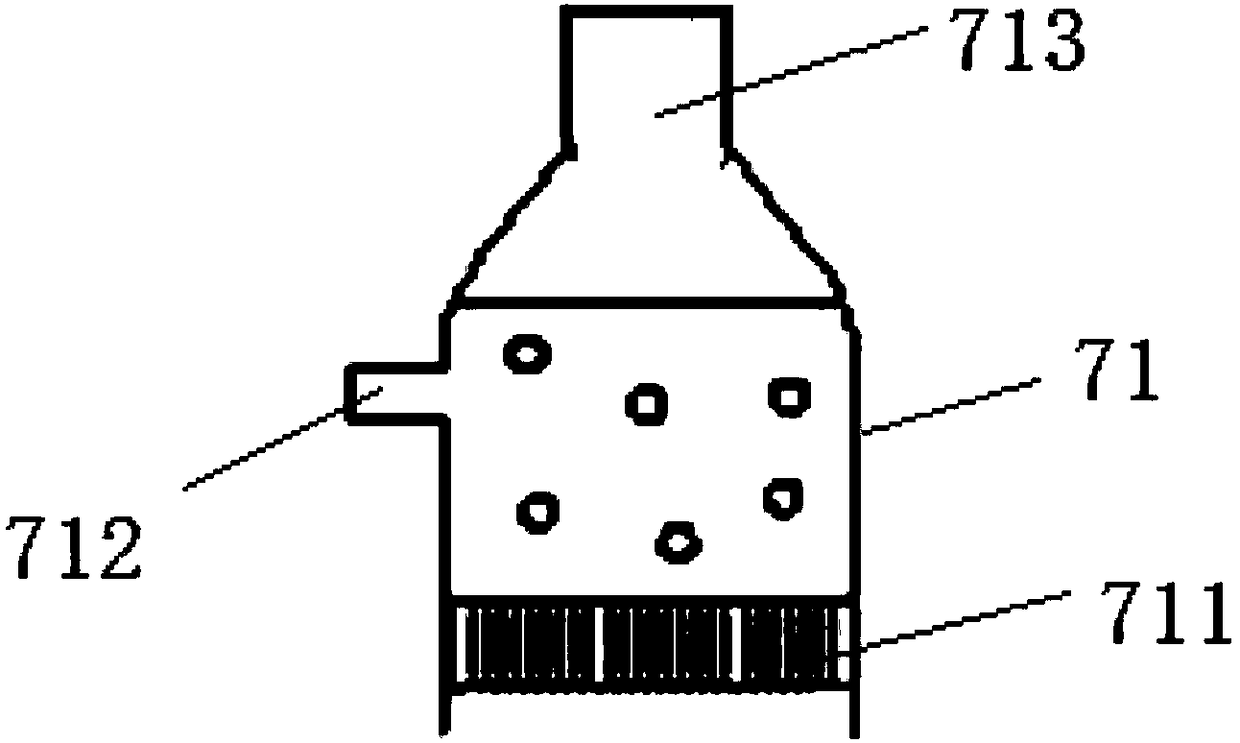

[0116] The temperature control system sets the temperature of the reactor at 100°C, controls the cryogenic cold trap to about 0°C, air enters the reactor through the sand core aeration plate, and 200ppm dibenzothiophene simulated oil enters the reactor from the liquid phase feed port. Add 0.8g Co(salen)Y into the reaction system, the air velocity is 100mL / min, and the simulated oil volume is 100mL. Add 100mL of glass spring packing to the reactor, so that all the feed liquid enters the packing, wherein, the diameter of a single packing is 4mm-6mm, and the length is 10-16mm. React under normal pressure for 4 hours, take a sample after the reaction process, filter the sample and analyze by gas chromatography to calculate the desulfurization rate to be 97.91%. Desulfurization rate = (initial amount of dibenzothioph...

Embodiment 3

[0117] Embodiment 3 desulfurization treatment

[0118] The desulfurization device is consistent with Example 2.

[0119] The temperature control system sets the temperature of the reactor at 60°C, controls the low-temperature cold trap to about 0°C, air enters the reactor through the sand core aeration plate, and 500ppm dibenzothiophene simulated oil enters the reactor from the liquid phase feed port. Add 0.8g Co(salen)Y into the reaction system, the air velocity is 100mL / min, and the simulated oil volume is 100mL. React under normal pressure for 4 hours, take a sample after the reaction process, filter the sample and analyze by gas chromatography to calculate the desulfurization rate to be 35.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com