Carbon nanometer material with surface carboxyl functionalized, preparation method of carbon nanometer material and application of carbon nanometer material

A carbon nanomaterial, carboxyl functionalization technology, applied in the field of materials, can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

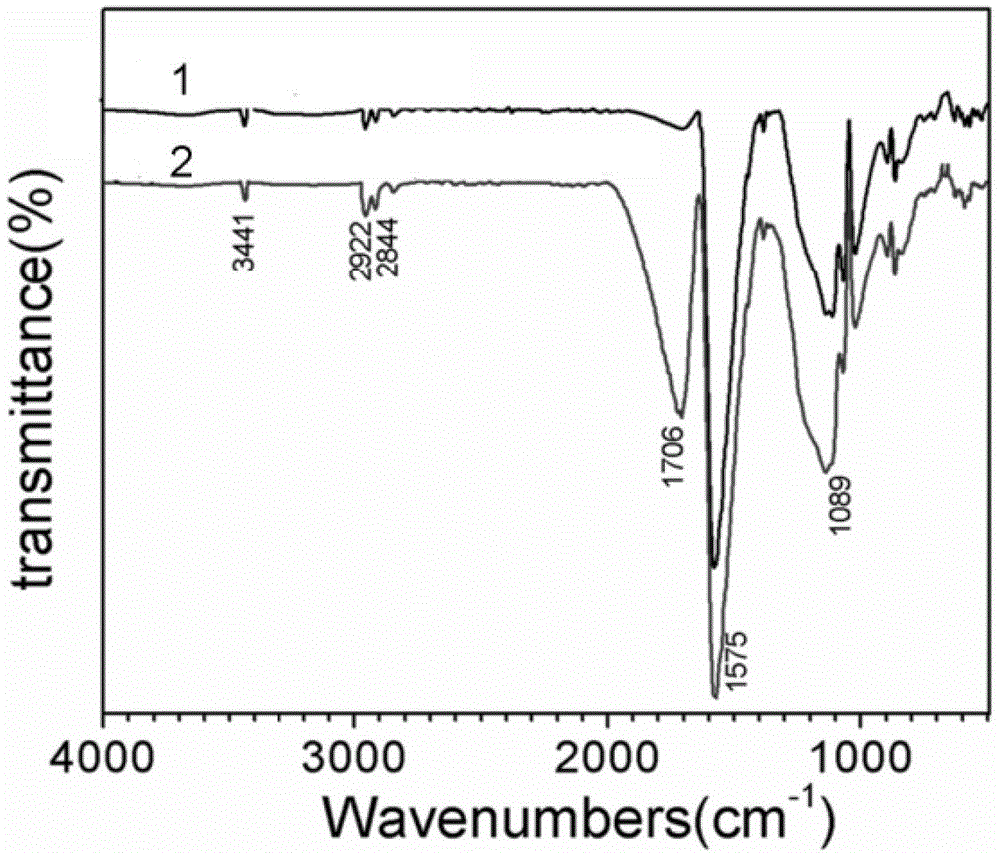

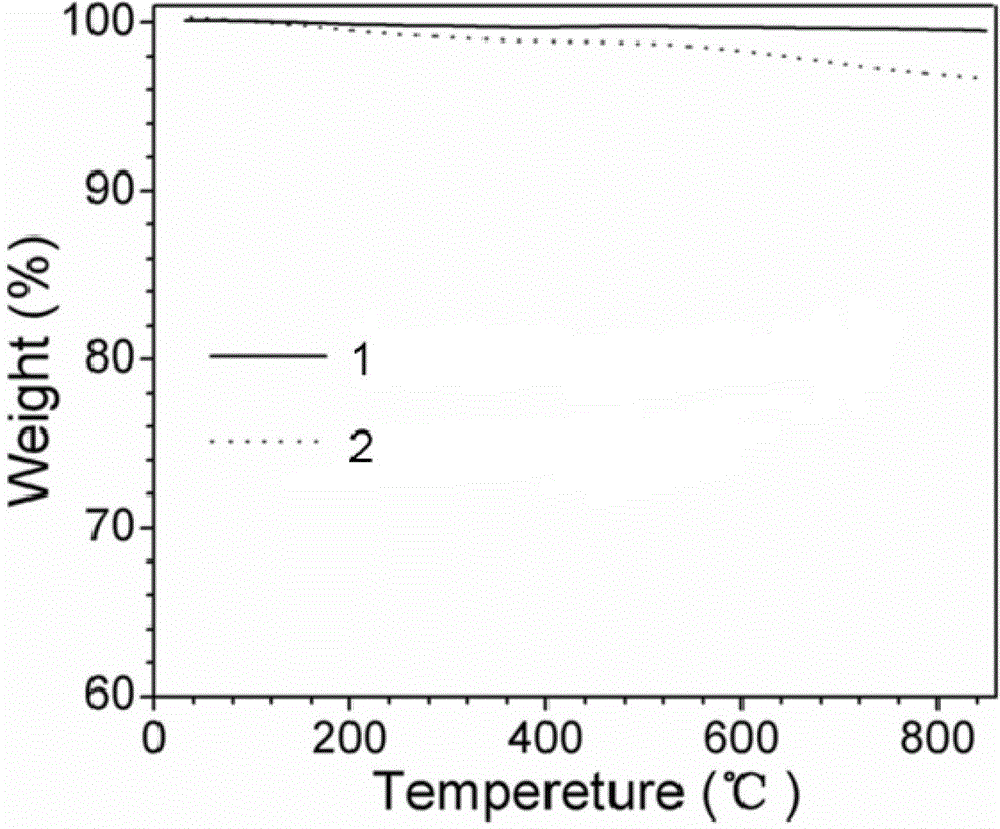

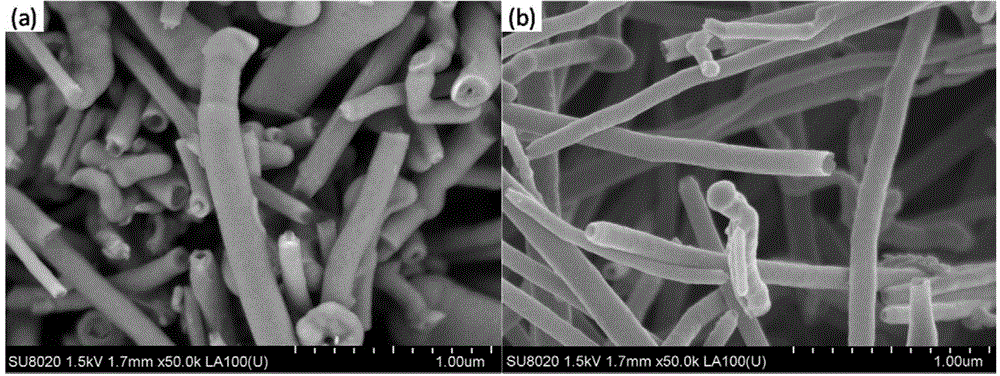

[0038] (1) Preparation of functionalized carbon nanofibers containing acid chloride groups: In a 250mL three-neck flask, add 100mg of carbon nanofibers (Chengdu Organic Chemical Co., Ltd., TNCF), add 100mL of N,N-dimethylformamide, Ultrasound for 5 minutes, the carbon nanofibers are evenly dispersed, then add 1g of oxalyl chloride and 3g of aluminum trichloride, react at 20°C for 72 hours, filter with a 0.45μm polyvinylidene fluoride microporous filter membrane to separate the filter residue, which is the acid chloride group functionalized carbon nanofibers.

[0039] (2) Preparation of surface carboxyl-functionalized carbon nanofibers: In a 250mL beaker, add 100mL of 1mol / L hydrochloric acid aqueous solution, then add 100mg of functionalized carbon nanofibers containing acid chloride groups, ultrasonically disperse for 5 minutes, and let stand 12 hours, then filtered with a 0.45 μm polyvinylidene fluoride microporous membrane, and the filter residue was the separated carboxyl-...

Embodiment 2

[0041] (1) Preparation of functionalized carbon nanofibers containing acid chloride groups: In a 250mL three-neck flask, add 100mg of carbon nanofibers (Chengdu Organic Chemical Co., Ltd., TNCF), add 100mL of N,N-dimethylformamide, Ultrasonic for 5 minutes, the carbon nanofibers are evenly dispersed, then add 2g of oxalyl chloride and 3g of aluminum trichloride, react at 25°C for 48 hours, filter with a 0.45μm polyvinylidene fluoride microporous filter membrane to separate the filter residue, which is the acid chloride group functionalized carbon nanofibers.

[0042] (2) Preparation of surface carboxyl-functionalized carbon nanofibers: In a 250mL beaker, add 100mL of 1mol / L hydrochloric acid aqueous solution, then add 100mg of functionalized carbon nanofibers containing acid chloride groups, ultrasonically disperse for 5 minutes, and let stand for 12 hours, and then filtered with a 0.45 μm polyvinylidene fluoride microporous membrane, and the filter residue was the separated c...

Embodiment 3

[0047] (1) Preparation of functionalized carbon nanofibers containing acid chloride groups: In a 250mL three-neck flask, add 100mg of carbon nanofibers (Chengdu Organic Chemical Co., Ltd., TNCF), add 100mL of N,N-dimethylformamide, Ultrasonic for 5 minutes, the carbon nanofibers are evenly dispersed, then add 4g of oxalyl chloride and 3g of aluminum trichloride, react at 30°C for 48 hours, filter with a 0.45μm polyvinylidene fluoride microporous filter membrane to separate the filter residue, which is the acid chloride group functionalized carbon nanofibers.

[0048] (2) Preparation of surface carboxyl-functionalized carbon nanofibers: In a 250mL beaker, add 100mL of 1mol / L hydrochloric acid aqueous solution, then add 1g of functionalized carbon nanofibers containing acid chloride groups, ultrasonically disperse for 5 minutes, and let stand 12 hours, then filtered with a 0.45 μm polyvinylidene fluoride microporous membrane, and the filter residue was the separated carboxyl-fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com