Application of MVR (Mechanical Vapor Recompression) crystallization evaporator to industrialized production of anhydrous sodium sulphate

An evaporator and sodium sulfate technology, which is applied in the chemical industry, inorganic chemistry, alkali metal compounds, etc., can solve the problems of high production cost, high energy consumption, and high investment cost, and achieve energy saving, low evaporation temperature, and low operating cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

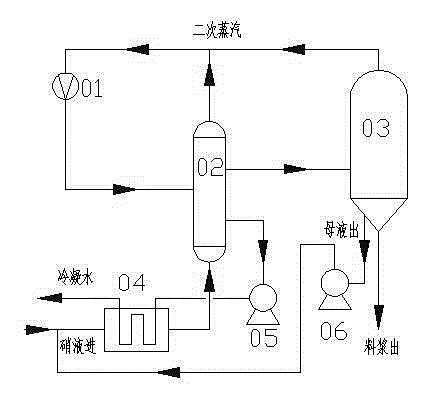

Image

Examples

Embodiment 1

[0015] Heat 1 ton of nitric solution containing 25% sodium sulfate and 0.3% sodium chloride (by mass percentage) to 95°C and pump it into the MVR (vacuum) crystallization evaporator, start the compressor, start to evaporate, and the secondary steam passes through the compression temperature Raise it to 110°C, send it to the heating chamber to heat the material, and keep the material in a boiling state. When concentrated to sodium sulfate supersaturated, began to discharge.

[0016] The specific process parameters are as follows:

[0017] Material name sodium sulfate solution Solvent water feed concentration 25% Concentration saturation concentration Total amount of feed 1 ton Evaporation temperature 90℃ Total evaporation 480Kg Average evaporation 120Kg / h average energy consumption 37.5KW / ton

Embodiment 2

[0019] Heat 10 tons of nitric solution containing 30% sodium sulfate and 0.3% sodium chloride (by mass percentage) to 90°C and pump it into the MVR (vacuum) crystallization evaporator, start the compressor, start to evaporate, and the secondary steam passes through the compression temperature Raise it to 105°C, send it to the heating chamber to heat the material, and keep the material in a boiling state. The secondary steam condensate heats the liquid nitric acid through the plate and frame heat exchanger, and the heated liquid nitric acid enters the evaporation chamber, and when it is concentrated to the supersaturated state of sodium sulfate, it is pumped into the crystallizer to start discharging.

[0020] The specific process parameters are as follows:

[0021] Material name sodium sulfate solution Solvent water feed concentration 30% Concentration saturation concentration Total amount of feed 10 tons Evaporation temperature 90℃ Tot...

Embodiment 3

[0023] Heat 30,000 tons of nitric solution containing 30% sodium sulfate and 0.3% sodium chloride (by mass percentage) to 90°C and pump it into the MVR (vacuum) crystallization evaporator, start the compressor, and start to evaporate, and the secondary steam is compressed The temperature rises to 105°C, and the material is sent to the heating chamber to heat the material to keep the material in a boiling state. The secondary steam condensate heats the liquid nitric acid through the plate and frame heat exchanger, and the heated liquid nitric acid enters the evaporation chamber, and when it is concentrated to the supersaturated state of sodium sulfate, it is pumped into the crystallizer to start discharging.

[0024] The specific process parameters are as follows:

[0025] Material name sodium sulfate solution Solvent water feed concentration 30% Concentration saturation concentration Total amount of feed 30000 tons Evaporation temperature 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com