Method for preparing ZrB2-SiC anti-ablation coating from in-situ reaction

An in-situ reaction, zrb2-sic technology, applied in the field of preparation of ZrB2-SiC ablation resistant coatings on the surface of carbon/carbon (C/C) composite materials, can solve the problems of uncontrollable performance, uneven distribution, coating and substrate Problems such as poor bonding performance to achieve the effect of improving ablation resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

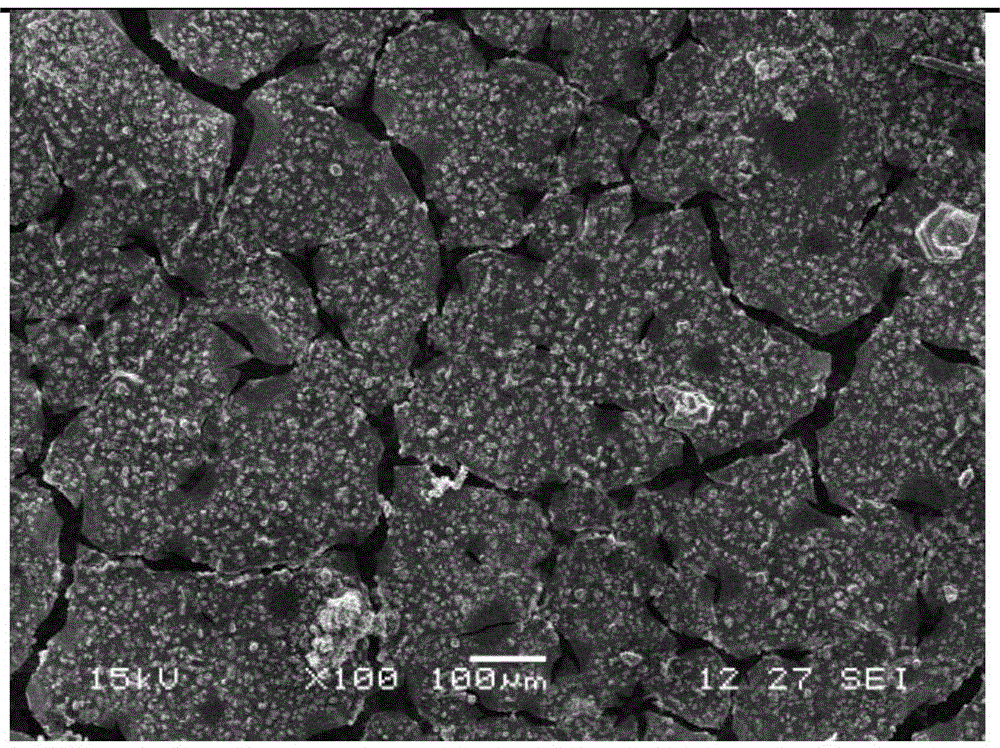

[0022] Step 1, pretreat the C / C composite material sample; the density obtained by the isothermal chemical vapor infiltration method is 1.67-1.76g / cm 3 The carbon / carbon composite material, after processing it to the size of Φ30mm×10mm, use 400 # Sandpaper to polish. The polished C / C composites were ultrasonically cleaned with tap water in turn, and air-dried. When cleaning, the ultrasonic frequency used is 40KH Z , the ultrasonic power is 100W, and the cleaning time is 15min;

[0023] Step 2, prepare a SiC transition layer on the surface of the C / C composite material; weigh 30g of Si powder, 6g of C powder and 3g of Al 2 o 3 pink. Place in a turpentine ball mill jar, take different numbers of agate balls with different diameters into the rosin ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours, and use it as a powder for later use. Put the powder into the graphite crucible, then place the dried C / C composite material sample...

Embodiment 2

[0027] Step 1, pretreat the C / C composite material sample; the density obtained by the isothermal chemical vapor infiltration method is 1.67-1.76g / cm 3 The carbon / carbon composite material, after processing it to the size of Φ30mm×10mm, use 800 # Sandpaper to polish. The polished C / C composites were ultrasonically cleaned with tap acetone in turn, and air-dried. When cleaning, the ultrasonic frequency used is 40KH Z , the ultrasonic power is 100W, and the cleaning time is 15min.

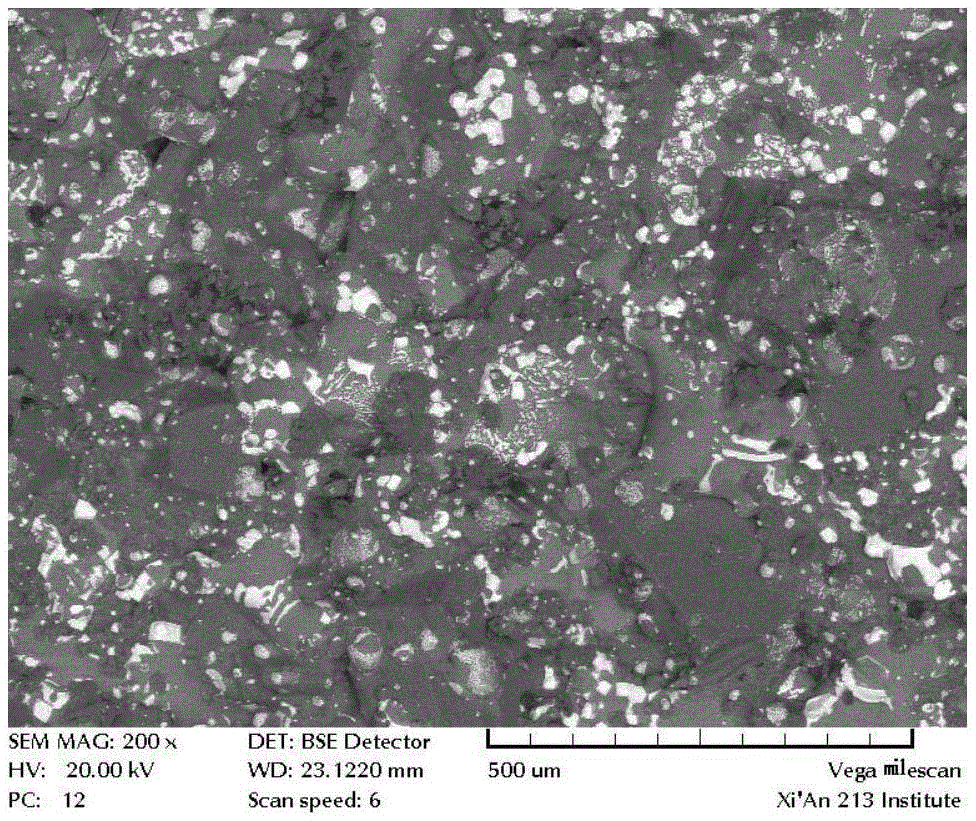

[0028] Step 2, prepare a SiC transition layer on the surface of the C / C composite material; weigh 30g of Si powder, 6g of C powder and 2g of Al 2 o 3 pink. Place in a turpentine ball mill jar, take different numbers of agate balls with different diameters into the rosin ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours, and use it as a powder for later use. Put the powder into the graphite crucible, then place the dried C / C composite material samp...

Embodiment 3

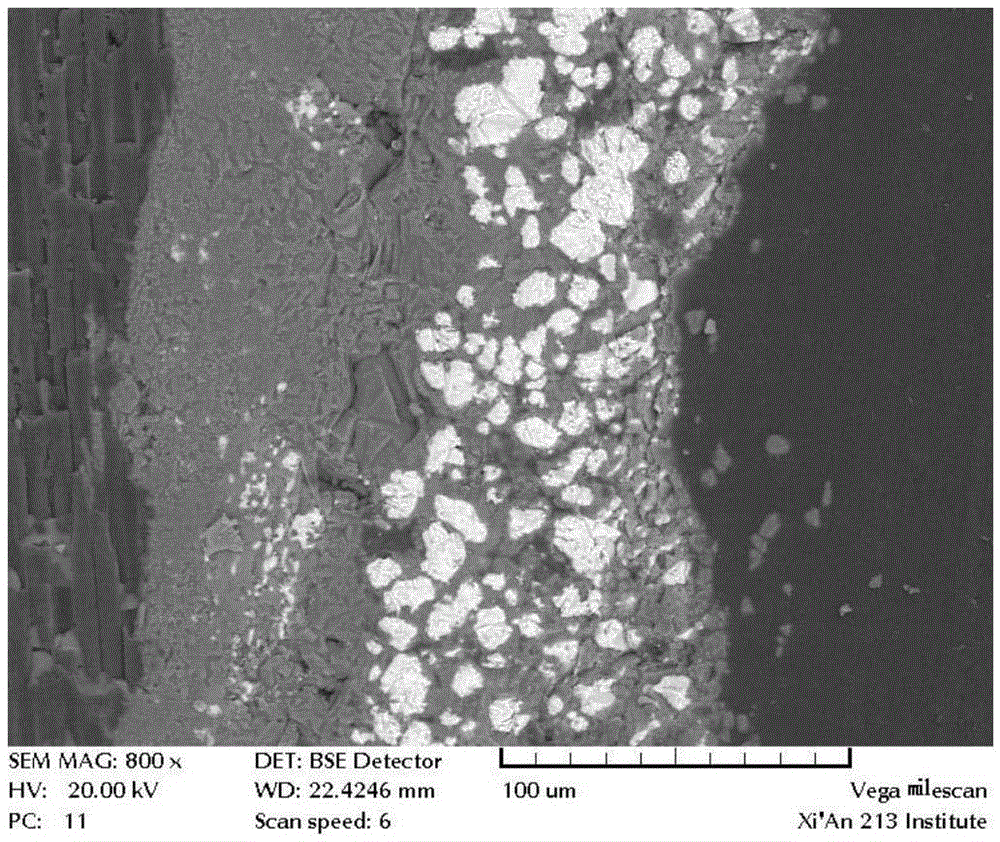

[0032] Step 1, pretreat the C / C composite material sample; the density obtained by the isothermal chemical vapor infiltration method is 1.67-1.76g / cm 3 The carbon / carbon composite material, after processing it to the size of Φ30mm×10mm, use 1500 # Sandpaper to polish. The polished C / C composites were ultrasonically cleaned with tap absolute ethanol in turn; air-dried. When cleaning, the ultrasonic frequency used is 40KH Z , the ultrasonic power is 100W, and the cleaning time is 15min.

[0033] Step 2, prepare a SiC transition layer on the surface of the C / C composite material; weigh 30g of Si powder, 5g of C powder and 3g of Al 2 o 3 pink. Place in a turpentine ball mill jar, take different numbers of agate balls with different diameters into the rosin ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours, and use it as a powder for later use. Put the powder into the graphite crucible, then place the dried C / C composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com