Low-shrinkage high-toughness ABS (Acrylonitrile Butadiene Styrene) composite and preparation method thereof

A composite material and low-shrinkage technology, applied in the field of ABS composite materials and its preparation, can solve the problems of poor impact strength, poor compatibility, poor oxidation resistance and ultraviolet radiation resistance, etc., and achieve good low temperature Impact properties, simple preparation process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

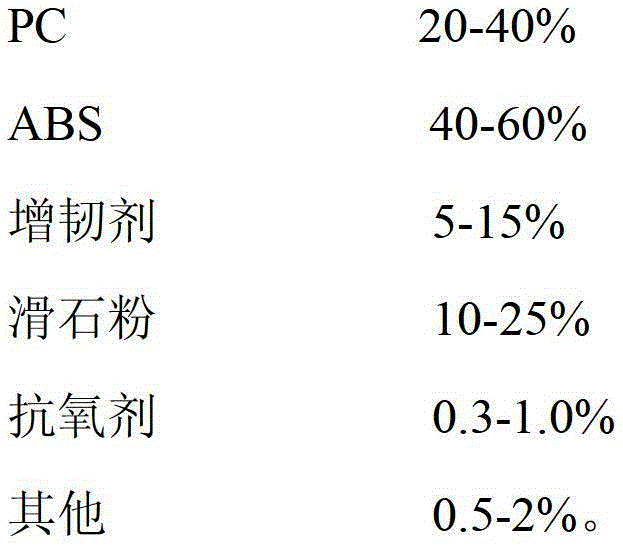

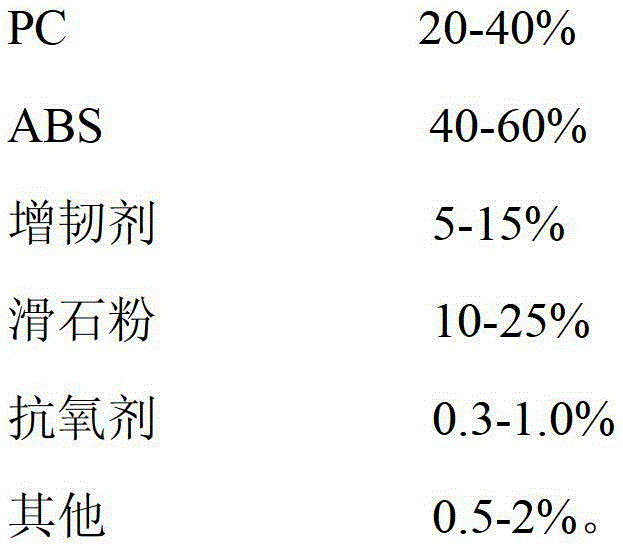

Embodiment 1

[0020] The raw materials are calculated by weight percentage, PC30% (pre-dried at 120°C for 4 hours), ABS47% (pre-dried at 80°C for 2 hours), grafted POE5%, talcum powder 15%, antioxidant 10761.0%, phase Compatible agent MBS2% was added to the mixer and mixed for 10 minutes, and the temperature of the extruder was set: Zone 1: 240 °C; Zone 2: 250 °C; Zone 3: 230 °C; Zone 4: 230 °C; Zone 5: 225 °C; Zone: 220°C; Zone 7: 210°C; Zone 8: 225°C; Zone 9: 250°C; Extrude the premixed material through the extruder, pull the strips and cool them in the water tank, blow dry and pull them to the cutting The feeder completes the granulation, and it is ready. After testing, the shrinkage is 0.21% at -20°C, and the impact strength can reach 28.7kJ / m 2 .

Embodiment 2

[0022] The raw materials are calculated by weight percentage, PC25% (pre-dried at 120°C for 6 hours), ABS51% (pre-dried at 80°C for 4 hours), grafted POE7%, talcum powder 15%, antioxidant 10760.5%, phase Compatible agent MBS1.5% was added to the mixer and mixed for 20 minutes, and the temperature of the extruder was set: Zone 1: 240°C; Zone 2: 250°C; Zone 3: 240°C; Zone 4: 240°C; Zone 5: 235°C ; Six zone: 230℃; Seven zone: 220℃; Eight zone: 240℃; Until the cutting machine completes pelletizing, it is ready. After testing, the shrinkage is 0.23% at -20°C, and the impact strength can reach 26.0kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com