Inorganic zinc-rich antirust skid-resistant coating

An anti-skid coating, inorganic zinc-rich technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unstable performance, anti-rust and anti-skid performance can not meet the needs of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

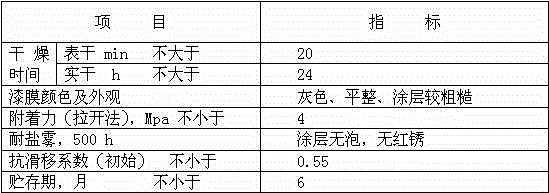

Image

Examples

Embodiment 1

[0050] The mass ratio of component A is as follows:

[0051] Ethanol: 20

[0052] Butanol: 40

[0053] Water: 5

[0054] Ethyl silicate: 35

[0055] The mass ratio of component B is as follows:

[0056] Polyvinyl butyral resin: 20

[0057] Anti-settling agent: 5

[0058] Zinc powder (ultrafine powder): 40

[0059] Emery: 30

[0060] Butanol 5

[0061] Component C:

[0062] Aluminum powder: 100;

[0063] Add 35Kg of ethyl silicate, 20Kg of ethanol, 40Kg of butanol, and 5Kg of water into the reaction kettle in component A, mix at a temperature of 40-80°C, react for 8-16 hours, filter after passing the inspection, and pack , as a backup component.

[0064] Mix 20Kg of polyvinyl butyral resin, 5Kg of anti-sedimentation agent, 40Kg of superfine zinc powder, 30Kg of corundum, and 5Kg of butanol in component B, filter and pack after passing the inspection, and use it as component B for later use.

[0065]Pack 100Kg of aluminum powder in component C after passing the inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com