Water soluble resin for impregnated paper backing plate and preparation method thereof

A technology of water-soluble resin and impregnated paper backing board, which is applied in papermaking, paper, textiles and papermaking, etc. It can solve the problems of reducing process safety, resin non-water solubility, environmental pollution, etc., and achieves strong toughness, stable emulsion, and reduced pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

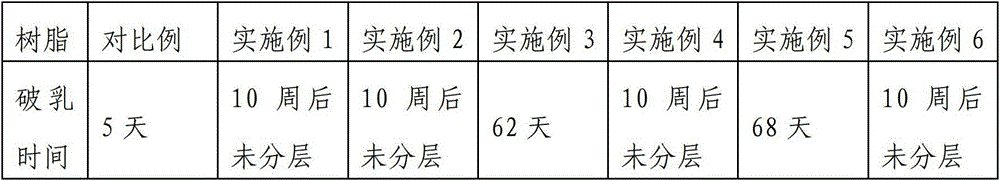

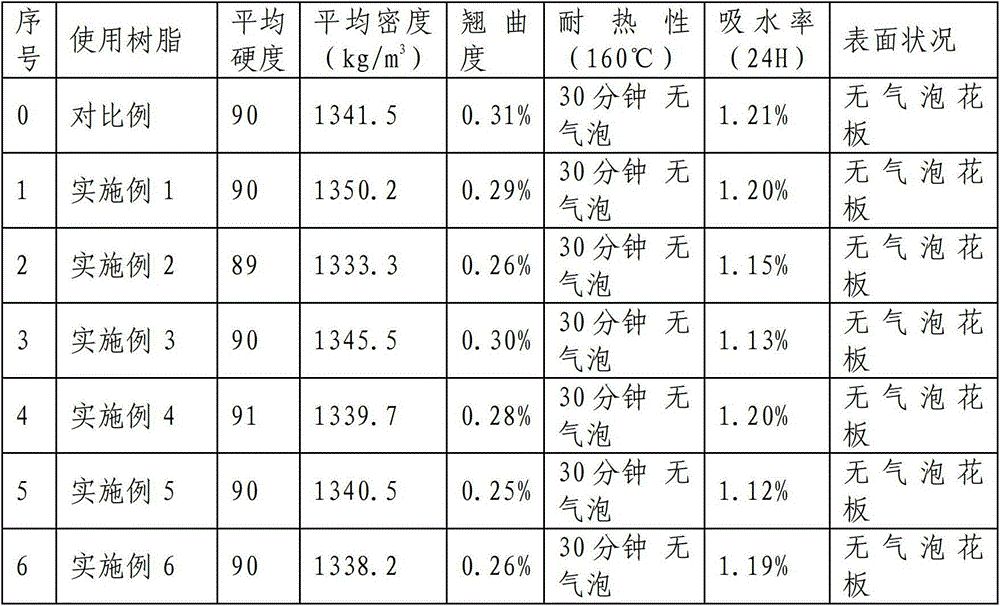

Examples

Embodiment 1

[0030] Put 1000g of phenol and 200g of cashew nut oil into the reactor, start the reactor to stir, add 30g of sodium hydroxide, heat up to 130°C, phenolize for 2 hours, cool down to 80°C, add 1466g of formaldehyde (37% formaldehyde aqueous solution), Add 400g of polyvinyl acetate emulsion, continue the constant temperature reaction until the viscosity of the mixture reaches 50~150cp, cool down to below 40°C, and obtain the water-soluble resin for impregnating the paper pad.

Embodiment 2

[0032] Put 1000g of phenol and 300g of tung oil into the reaction kettle, start the reaction kettle to stir, add 30g of potassium hydroxide, heat up to 130°C, phenolize for 2 hours, cool down to 70°C, add 1293g of formaldehyde (37% formaldehyde aqueous solution), add 300g of styrene-acrylic emulsion, continue to react at constant temperature until the viscosity of the mixture reaches 50~150cp, cool down to below 40°C, and obtain a water-soluble resin for impregnating the paper backing board.

Embodiment 3

[0034] Put 1000g of phenol and 400g of cashew nut oil into the reactor, start the reactor to stir, add 50g of sodium carbonate, heat up to 130°C, phenolize for 2 hours, cool down to 70°C, add 1725g of formaldehyde (37% formaldehyde aqueous solution), add 500g of silicon-acrylic emulsion, continue to react at constant temperature until the viscosity of the mixture reaches 50~150cp, cool down to below 40°C, and obtain a water-soluble resin for impregnating the paper backing board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com