Cavity resonance-based control method for reducing combustion noises of combustion engines

A control method and combustion noise technology, applied in the direction of engine control, electrical control, mechanical equipment, etc., to achieve the effect of low cost, short research and development cycle, simple and effective control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment.

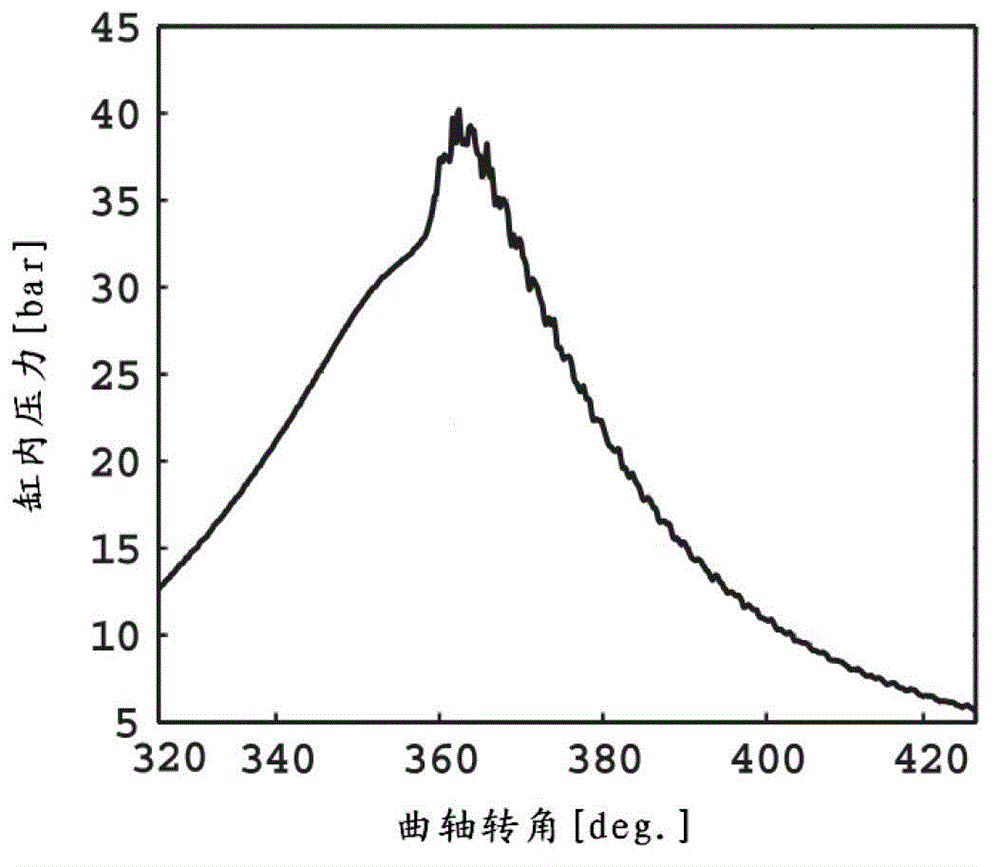

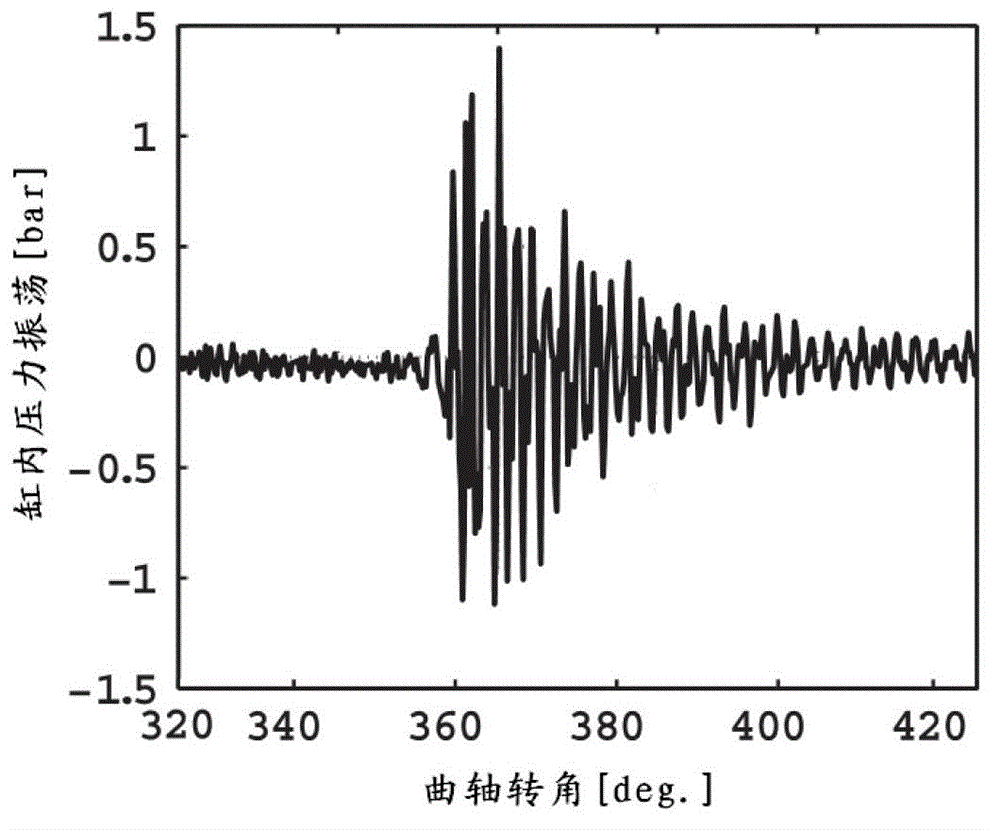

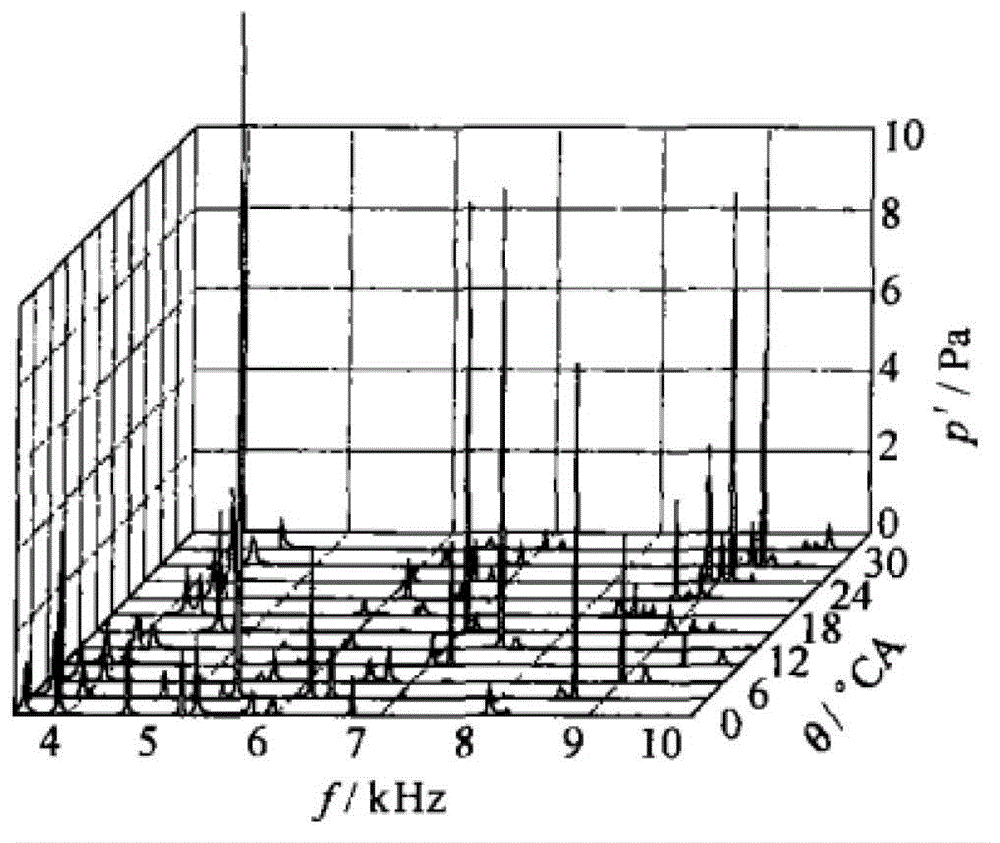

[0016] Aiming at the need of internal combustion engines, especially miniaturized internal combustion engines, to reduce combustion noise, the present invention proposes a control method for reducing combustion noise of internal combustion engines based on cavity resonance. In the late stage of the compression stroke of the internal combustion engine (near the top dead center of the piston), the severe vibration energy caused by the high-frequency pressure oscillation caused by the combustion of the mixture in the cylinder is transmitted outward, resulting in harsh noise. The root cause of the oscillation of the cylinder pressure is the cavity resonance of the combustion chamber caused by the combustion process, that is, when the frequency of the pressure wave in the combustion chamber of the internal combustion engine propagating back and forth in the combustion chamber is close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com