Doped graphene flexible transparent electrode and preparation method thereof

A transparent electrode and vinyl flexible technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reduced mobility and reduced current-carrying density at grain boundaries, and achieve high light transmittance and low resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

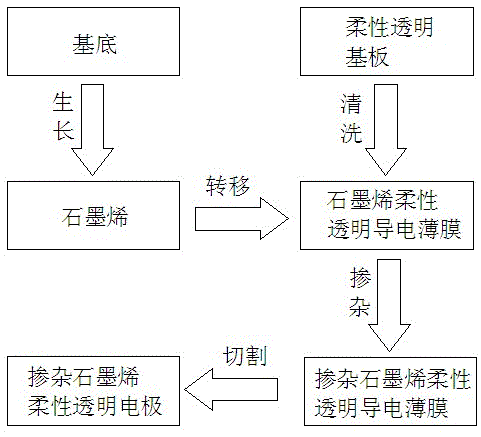

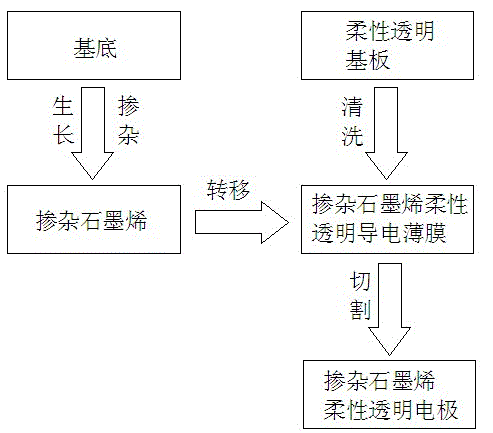

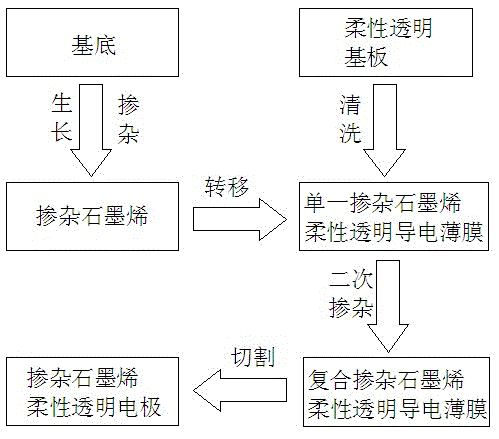

[0036] like figure 1 As shown, using non-replacement doping, the preparation method of the doped graphene flexible transparent electrode of the present embodiment comprises the following steps:

[0037] 1) Using chemical vapor deposition method, graphene is grown on the substrate under the condition of gaseous carbon source and protective gas;

[0038] 2) Transfer the graphene grown on the substrate to a flexible transparent substrate to obtain a graphene flexible transparent conductive film;

[0039] 3) Soak and dope the graphene flexible transparent conductive film in a solution containing a chemical doping agent to obtain a doped graphene flexible transparent conductive film;

[0040] 4) Cut and shape the doped graphene flexible transparent conductive film to obtain a doped graphene flexible transparent electrode.

[0041] In the step 1), the preferred process conditions are: the substrate is copper foil, the gas carbon source is methane, the protective gas is nitrogen, t...

Embodiment 2

[0045] The difference between this example and Example 1 lies in step 3). In this example, the graphene flexible transparent conductive film is doped with metal nanoparticles. The specific doping method is: preparing metal nanoparticles of required size, Nanoparticles of different shapes such as nanowires (the metal nanoparticles are preferably selected from one or more of Au, Ag, Fe, Cu, and Pt), uniformly coated on the graphene surface on a flexible transparent substrate, and multi-stage The temperature-programmed annealing treatment forms the graphene doped with metal nanoparticles, and obtains a flexible transparent conductive film doped with graphene.

[0046] The sheet resistance of the graphene-doped flexible transparent electrode prepared in this example is between 20-150 Ω / sq, and the light transmittance is between 90.1-95.5%.

Embodiment 3

[0048] The difference between this example and Example 1 lies in step 3). In this example, the graphene flexible transparent conductive film is doped with metal nanoparticles. The specific doping method is: the mixture of the metal precursor and the reducing agent Uniformly coat the surface of graphene on a flexible transparent substrate, and then reduce the precursor by ultraviolet light to obtain metal nanoparticles uniformly dispersed on the surface of graphene, and wash off other reaction products with water to form graphene doped with metal nanoparticles , to obtain doped graphene flexible transparent conductive film.

[0049] The sheet resistance of the graphene-doped flexible transparent electrode prepared in this example is between 5 and 150 Ω / sq, and the light transmittance is between 89.0 and 96.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com