Low smoke zero halogen (LSZH) insulation and extrusion soft copper bar and manufacturing method thereof

A soft copper busbar and extruder technology, which is applied in the direction of insulating conductors, insulating cables, and insulating conductors/cables, can solve the problems of cracking of heat-shrinkable tubes, poor corrosion resistance, and decreased electrical conductivity of copper bars, etc., and achieves good reliability. The effect of bendability, high pressure resistance, and large bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

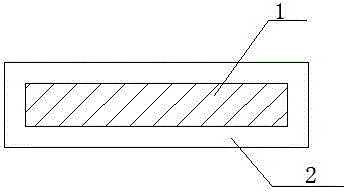

[0015] A low-smoke, halogen-free insulated extruded soft copper bar, comprising a copper bar conductor 1 and a low-smoke, halogen-free insulating layer 2, the copper bar conductor is extruded and wrapped with a low-smoke, halogen-free insulating layer; the copper bar conductor is strip-shaped copper row, the copper material is extruded into a strip-shaped copper row through a copper continuous extrusion machine; the copper continuous extrusion machine uses a mold made of a cobalt-based alloy material to continuously extrude and anneal the copper material; the low-smoke and halogen-free insulating layer is The low-smoke and halogen-free insulating material adopts the cable insulation extrusion method, and the low-smoke and halogen-free insulating material is tightly squeezed and wrapped on the strip-shaped copper bar through a rectangular tube dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com