Method for producing solar cell and film-producing device

A technology of solar cells and manufacturing methods, applied to circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

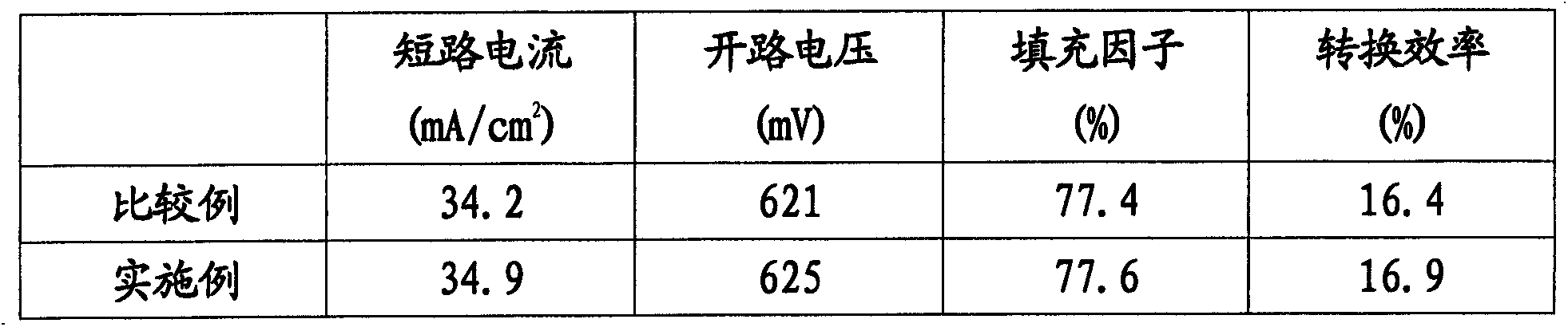

[0055] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, this invention is not limited to the following Example.

[0056] [Example, comparative example]

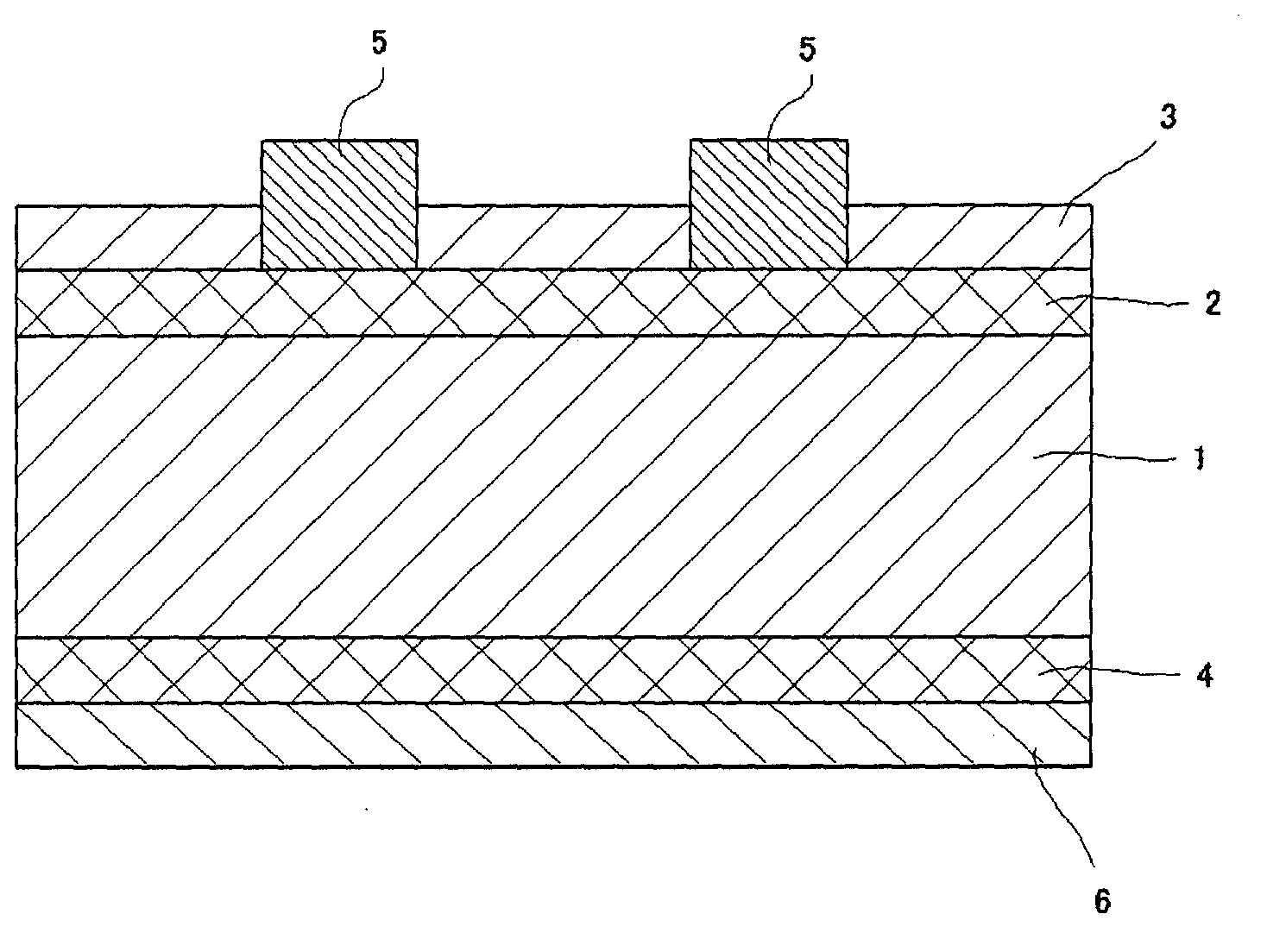

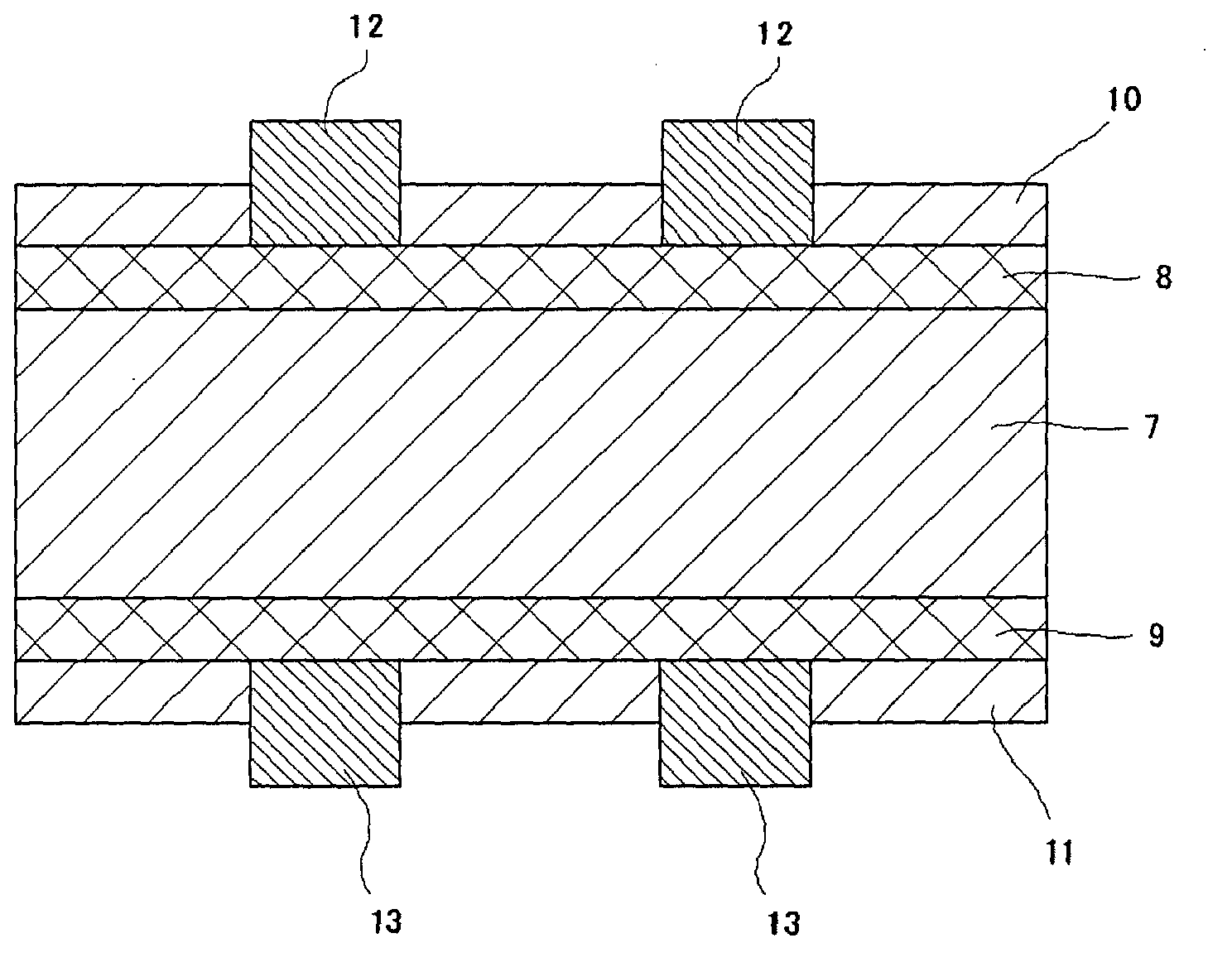

[0057] The outer diameter of a p-type silicon substrate made of p-type single crystal silicon with a resistivity of about 1 Ω·cm, which is doped with boron and sliced into a thickness of 0.2 mm, is made into a square plate shape with a side of 15 cm. . Then, the p-type silicon substrate was immersed in a fluoronitric acid solution for 15 seconds to perform damage etching, and further, by chemical etching in a 70° C. solution containing 2% by mass of KOH and 2% by mass of IPA for 5 minutes, then using Wash and dry to form a textured structure on the surface of the p-type silicon substrate. Next, for the p-type silicon substrate, in POCl 3 An n layer was formed on a p-type silicon substrate by a thermal diffusion method in a gas atmosphere at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com