Artificial vertebral body

A vertebral body and artificial technology, applied in prosthetics, medical science, spinal implants, etc., can solve problems such as difficulty in providing fusion, high recurrence rate of in situ tumors, poor long-term effect, etc., to improve adhesion, Improvement effect, effect of increasing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

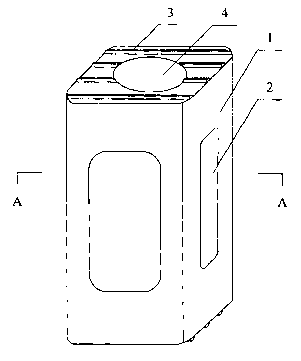

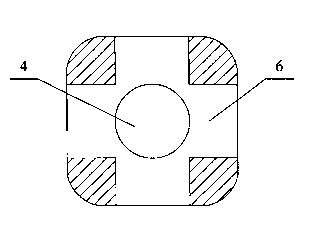

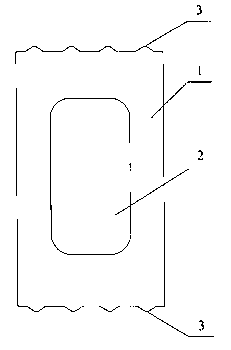

[0022] like Figure 1 to Figure 3 As shown, the artificial vertebral body is made of hydroxyapatite and zirconia bioceramic composite material, the artificial vertebral body 1 is a hollow columnar structure, its cross-section is a square with rounded corners of the central circle 4, and its area And the shape is similar to the corresponding vertebral body of the human body. The tooth-shaped protrusion strips 3 are formed on the upper and lower end surfaces of the artificial vertebral body 1, and the tooth-shaped protrusion strips 3 can ensure sufficient adhesion between the vertebral body and the cortical bone. On the four faces of the artificial vertebral body 1, there are respectively rectangular through holes 2, and the rectangular through holes 2 on the four faces form a radial cross-shaped through cavity 6, which greatly increases the Bone space, improve the effect of bone fusion.

Embodiment 2

[0024] like Figure 4 As shown, the artificial vertebral body is made of hydroxyapatite and zirconia bioceramic composite material, the artificial vertebral body 1 is a hollow columnar structure, its cross section is a square with rounded corners of the central circle 4, and its area And the shape is similar to the corresponding vertebral body of the human body. The tooth-shaped protrusion strips 3 are formed on the upper and lower end surfaces of the artificial vertebral body, and the tooth-shaped protrusion strips can ensure sufficient adhesion between the vertebral body and the cortical bone. On the four faces of the artificial vertebral body 1, there are respectively rectangular through holes 2, and the rectangular through holes 2 on the four faces form a radial cross-shaped through cavity 6, each of the cross-shaped through cavity 6 The center of one side is also provided with a reinforcing tibia 5, and the cross-shaped cavity 6 greatly increases the space for osteogenes...

Embodiment 3

[0026] Artificial vertebral body 1 is made of hydroxyapatite and zirconia bioceramic composite material, and described artificial vertebral body 1 is hollow columnar structure, and its cross section is circular, and its area and shape are similar to the corresponding vertebral body of human body. The tooth-shaped protrusion strips 3 are formed on the upper and lower end surfaces of the artificial vertebral body 1, and the tooth-shaped protrusion strips 3 can ensure sufficient adhesion between the vertebral body and the cortical bone. On the outer peripheral surface of the artificial vertebral body 1, there are four evenly distributed rectangular through holes 2 with rounded corners. These four rectangular through holes 2 form a radial cross-shaped through cavity 6, which greatly increases the Increased bone formation space, improve the effect of bone fusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com