Water wall base cone assembly welding and heat treatment device and method

A technology of heat treatment device and heat treatment method, applied in heat treatment furnaces, heat treatment equipment, auxiliary devices, etc., can solve the problems of inability to meet use requirements, large welding stress and deformation, and achieve the effect of eliminating stress after surfacing and avoiding bending deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

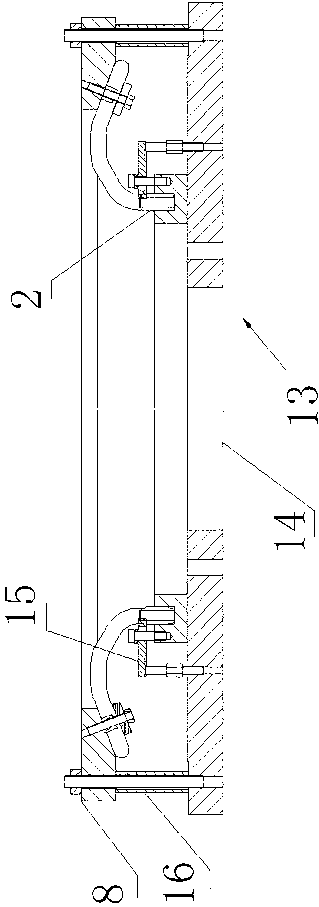

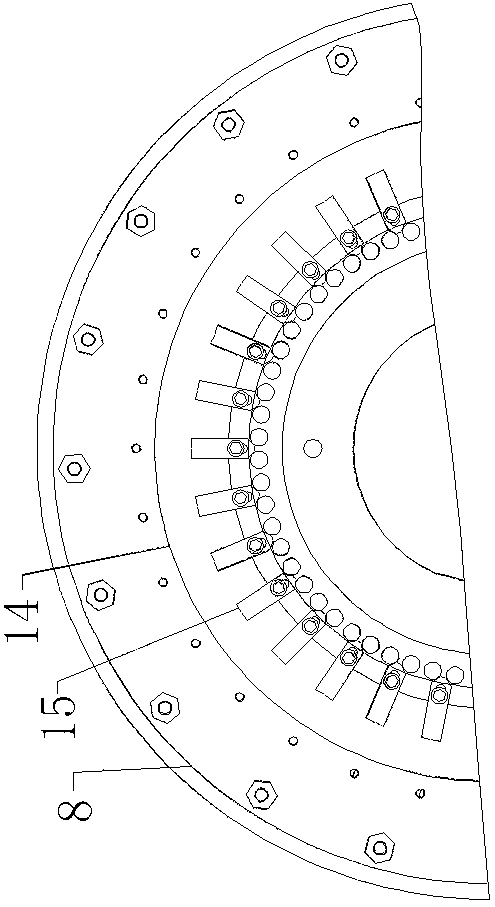

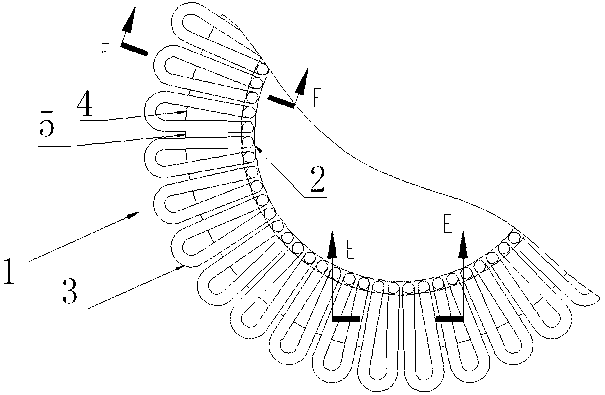

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, a water-cooled wall bottom cone 1 set of butt welding, heat treatment device, the water-cooled wall bottom cone is composed of ring forging 2, special-shaped elbow 3, the first special-shaped The flat steel 4, the second special-shaped flat steel 5 and the annular surfacing layer 6 are formed by welding, and the device includes a docking device 7 and a welding heat treatment device 13; Four positioning blocks 10 for outer circle positioning and end face support positioning of the ring forging, positioning ring 8 and positioning ring 11 for positioning the inner stop and the outer stop of the base of the docking device through bolts, wherein the positioning block and the ring forging are positioned through bolts; The inner side of the locating ring contains an inner conical surface matched with the special-shaped elbow, and the outer conical surface of the special-shaped elbow cooperates with the inner conical surface of t...

Embodiment 2

[0038] A water-cooled wall bottom cone group butt welding and heat treatment method, the positioning and clamping structure of each workpiece and device is as follows Figure 6 , 7 , 8, 9, and 10, the steps of the method include:

[0039] Step 1. Connect the ring forging with the four directional blocks on the base of the docking device through bolts. The bolts pass through the channel of the ring forging to position the ring forging and clamp the ring forging. support positioning;

[0040] Step 2. The inner seam of the positioning ring cooperates with the outer seam of the base of the docking device for positioning, and the bolts are used for circumferential orientation and the positioning ring is clamped;

[0041] Step 3. Match the outer cone surface of the special-shaped elbow to be welded with the inner cone surface of the positioning ring, and connect the positioning ring and bolts to perform circumferential positioning. The two pipe ends of the special-shaped elbow are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com