Method for preparing patterning silicon nanometer well array

A silicon nano-patterning technology, applied in gaseous chemical plating, manufacturing microstructure devices, and processes for producing decorative surface effects, etc. It can solve the period and diameter, and the depth can be precisely adjusted at the same time, and nano-well structures cannot be realized. problem, to achieve the effect of fast processing speed, low cost and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this scheme is described below in conjunction with examples, and the described examples cannot cover all scopes of the invention. Based on the examples in the present invention, all other examples obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

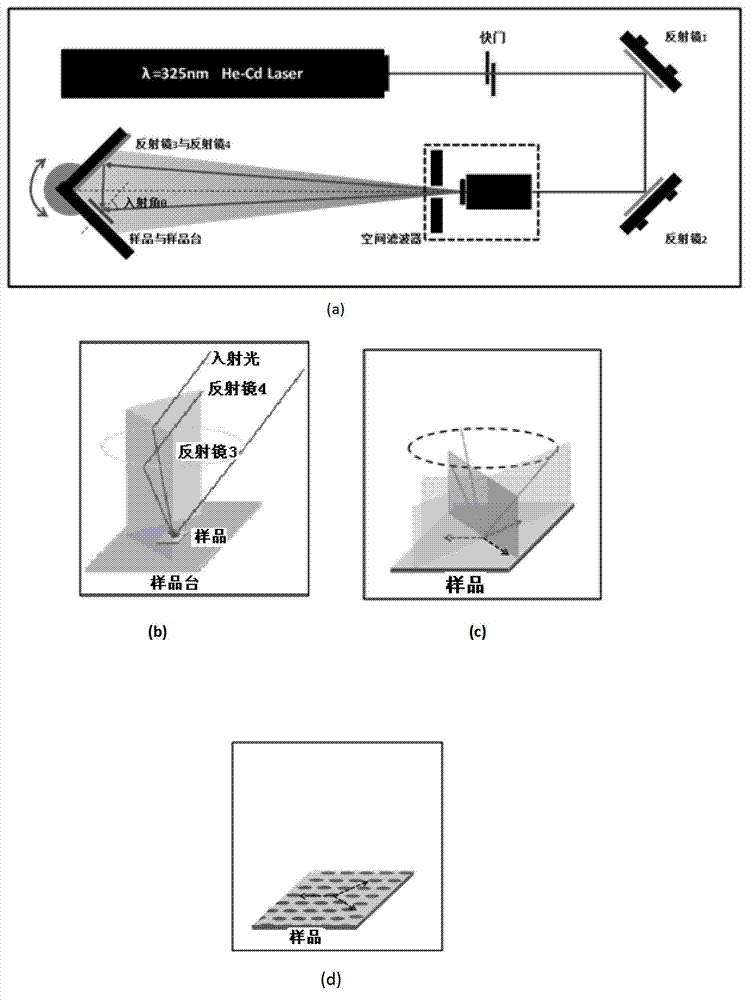

[0025] (1) Three-beam laser interference system: such as figure 1As shown in (a), a beam of 325nm laser is emitted by the He-Cd laser, passes through the electronic shutter, mirrors 1 and 2, and the spatial filter expands the beam to form a circular spot and irradiates the sample stage; figure 1 As shown in (b), the two mirrors (mirror 3 and mirror 4) form an angle of 120° to each other, and are perpendicular to the plane where the sample is placed, and the intersection point of the three surfaces is located in the center of the spot, so that the circular spot is divided into three equal parts. Among them, two beams of lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com