Wrapping cloth V belt and manufacture method thereof

A technology for wrapping cloth and canvas, applied in belts, transportation and packaging, and other household appliances, etc., can solve the problems of unreasonable composition of fiber film components, shortening the service life of products, and lack of support, so as to improve the lateral strength. performance, increased service life, improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

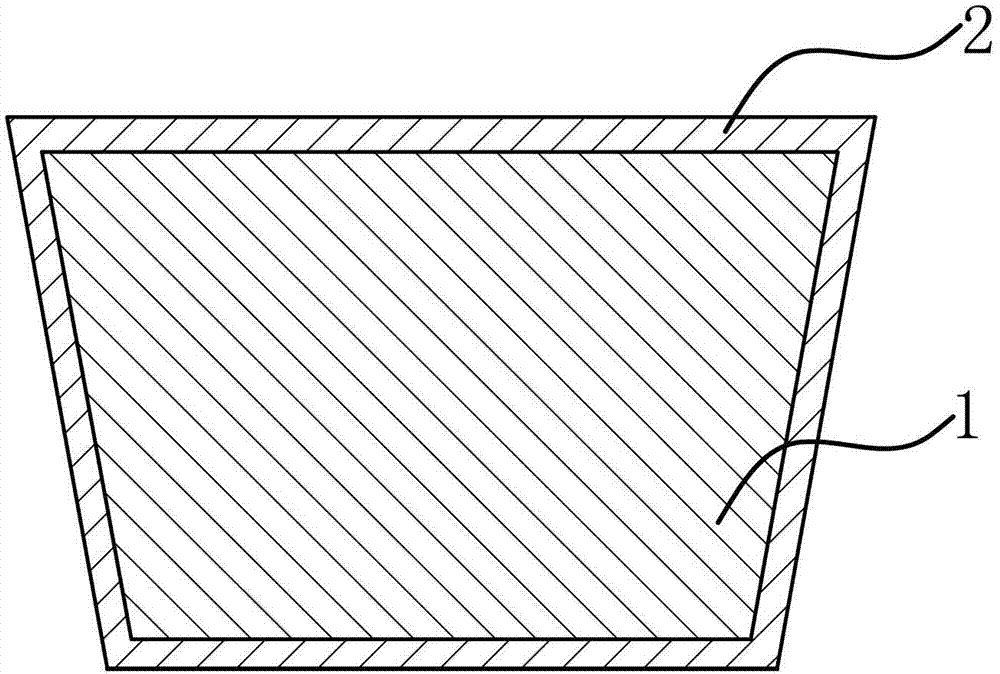

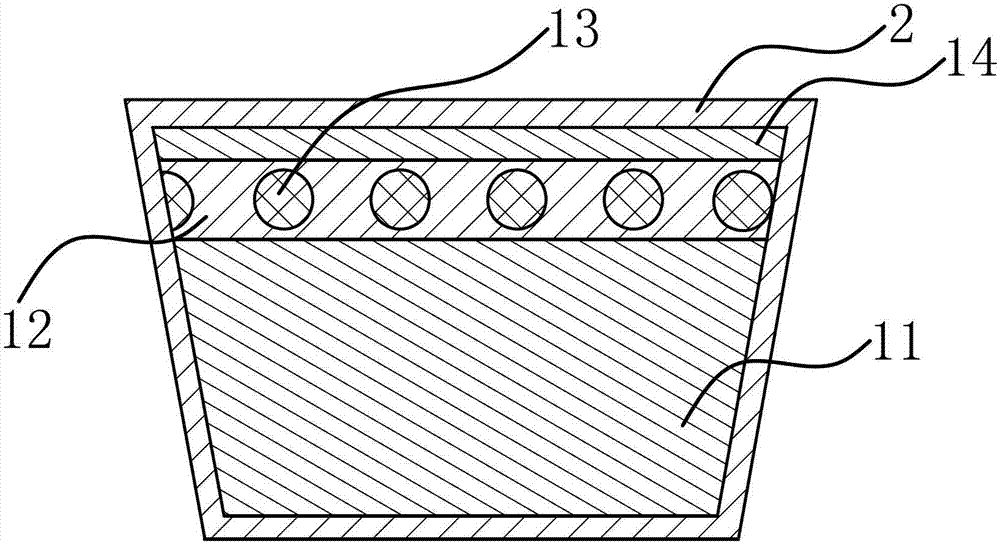

[0059] A cloth-covered V-belt, the V-belt comprises a core layer 1 and a cloth-covered layer 2 coated on the outer surface of the core layer, the core layer 1 sequentially includes a primer layer 11 made of fiber film from the bottom to the top , adhesive layer 12, polyester hard cord 13 and buffer adhesive layer 14. The covering layer adopts rubber-dipped canvas, and the short fibers are arranged in the transverse direction in the primer layer 11, and the transverse arrangement refers to the arrangement in the width direction of the covering cloth V-belt. Preferably, the polyester hard cord is completely wrapped in the viscose layer.

[0060] The concrete preparation method of above-mentioned wrapped cloth V-belt in the present embodiment is as follows:

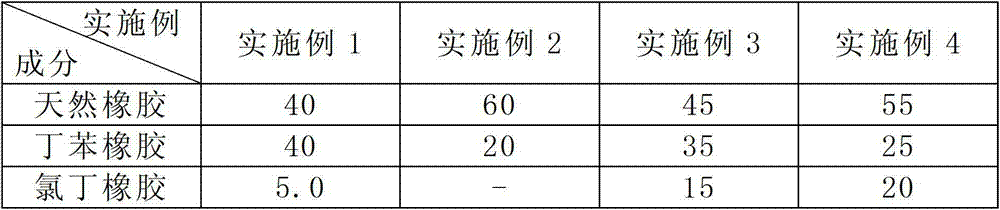

[0061] a, mixing: adopt the proportioning by weight of the composition of the fiber film described in the embodiment 1 of the above table 1, first mix the natural rubber, styrene-butadiene rubber, neoprene and reclaimed rub...

Embodiment 2

[0066] A cloth-covered V-belt, the V-belt comprises a core layer 1 and a cloth-covered layer 2 coated on the outer surface of the core layer, the core layer 1 sequentially includes a primer layer 11 made of fiber film from the bottom to the top , adhesive layer 12, polyester hard cord 13 and buffer adhesive layer 14. The covering layer is two layers, and the covering layer adopts rubberized canvas, and the warp density of the canvas is 38 threads / cm, and the weft density is 40 threads / cm; 11 is a horizontal arrangement, and the horizontal arrangement refers to the arrangement in the width direction of the cloth V-belt. As preferably, the polyester hard cord is completely wrapped in the viscose layer,

[0067] The concrete preparation method of above-mentioned wrapped cloth V-belt in the present embodiment is as follows:

[0068] a, mixing: the specific mixing method is consistent with the corresponding mixing method of embodiment 1, and will not be repeated here;

[0069] b...

Embodiment 3

[0073]A cloth-covered V-belt, the V-belt comprises a core layer 1 and a cloth-covered layer 2 coated on the outer surface of the core layer, the core layer 1 sequentially includes a primer layer 11 made of fiber film from the bottom to the top , adhesive layer 12, polyester hard cord 13 and buffer adhesive layer 14. The wrapping layer is two layers, and the wrapping layer adopts dipped canvas, and the warp density of the canvas is 37 threads / cm, and the weft density is 40 threads / cm; 11 is a horizontal arrangement, and the horizontal arrangement refers to the arrangement in the width direction of the V-belt. Preferably, the polyester hard cord is completely wrapped in the viscose layer.

[0074] The concrete preparation method of above-mentioned wrapped cloth V-belt in the present embodiment is as follows:

[0075] a, mixing: the specific mixing method is consistent with the corresponding mixing method of embodiment 1, and will not be repeated here;

[0076] b. Forming: put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com