Method and equipment for continuously refining liquid paraffin by virtue of by-product hydrochloric acid during chlorinated paraffin production

A technology of by-product hydrochloric acid and chlorinated paraffin, which is applied in the field of extraction towers, can solve the problems of restricting the use of hydrochloric acid and unattainable color, and achieve the effect of improving color, purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

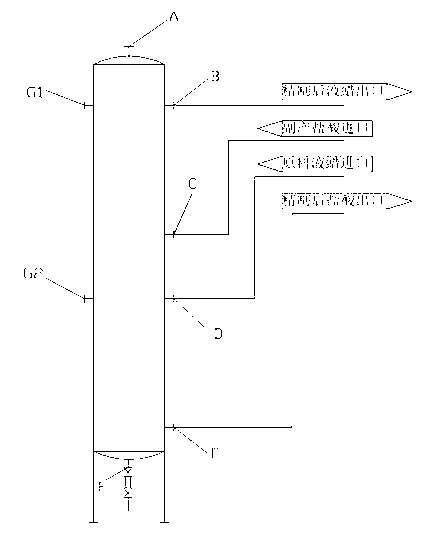

[0012] Embodiment: In the method of this embodiment, the chlorination reaction system and the acid system of chlorinated paraffin are continuous, and the liquid outlet of the by-product acid of the finished product must be higher than the extraction tower.

[0013] as attached figure 1 As shown, the raw material liquid wax enters the tower from the port D of the extraction tower, and the by-product hydrochloric acid enters the tower from the port C of the extraction tower. The raw material liquid wax and the by-product hydrochloric acid meet and extract each other between ports C and D. The moisture in the hydrochloric acid is taken away by the acid, aromatics and other mechanical impurities react with hydrochloric acid here and then precipitate to the bottom of the extraction tower, most of the free chlorine in the hydrochloric acid is taken away by the liquid wax.

[0014] The extracted liquid paraffin enters the chlorination reaction kettle from port B for chlorination reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com