A kind of low-cost boron-containing steel and its manufacturing method

A manufacturing method and low-cost technology, which are applied to low-cost boron-containing steel and its manufacturing field, can solve problems such as affecting B, and achieve the effects of low production cost, guaranteed solid solution boron content, and flexible manufacturing process

Active Publication Date: 2015-09-02

ANGANG STEEL CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, in the prior art, there is no clear limit to the content of O and N in the steel, or the limit range is relatively wide, which will cause the combination of O, N and B elements in the steel, affecting the contribution of B to the improvement of strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

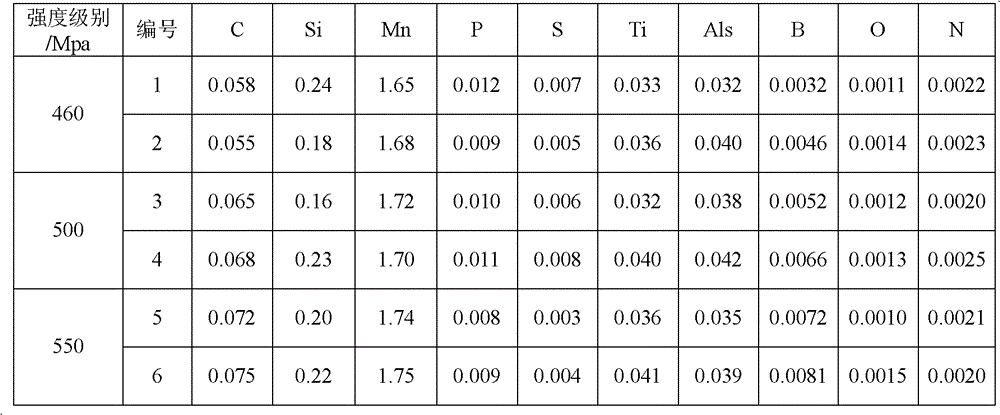

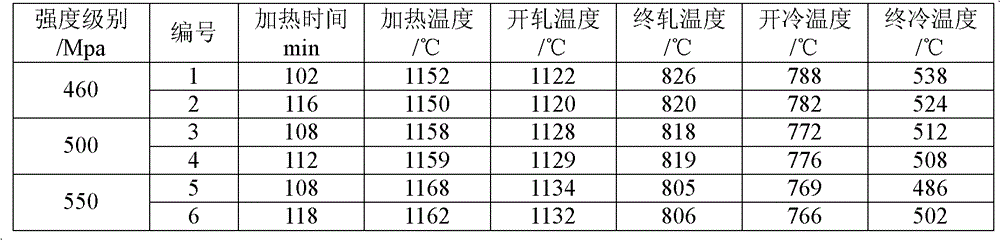

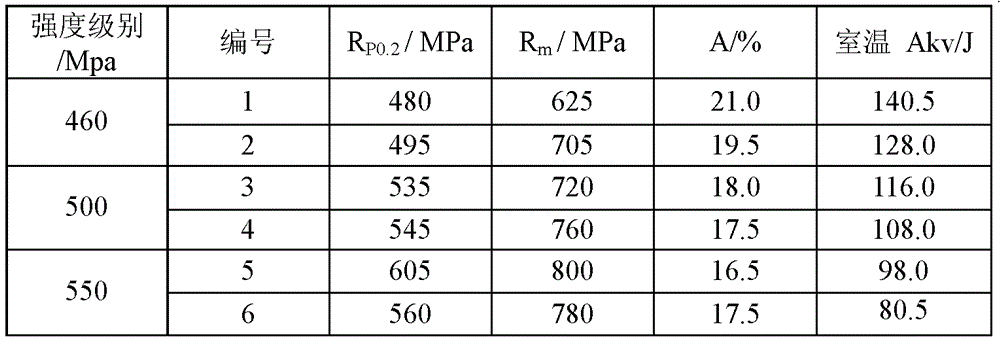

[0019] The chemical composition of the present invention is shown in Table 1, the actual process parameters of the present invention are shown in Table 2, and the physical mechanical properties of the present invention are shown in Table 3.

[0020] Table 1 Chemical composition, Wt%

[0021]

[0022] Table 2 Actual process parameters

[0023]

[0024] Table 3 physical mechanical properties

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a low-cost boron-containing steel and a manufacturing method thereof. The steel comprises the following chemical components by weight: 0.05%-0.08% of C, 0.10-0.25% of Si, 1.60%-1.80% of Mn, 0.03%-0.045% of Als, 0.030%-0.045% of Ti, 0.003%-0.009% of B, less than or equal to 0.025% of P, less than or equal to 0.015% of S, less than or equal to 0.0015% of O, less than or equal to 0.0025% of N, and the balance Fe and unavoidable impurities. At the later stage of LF (ladle furnace) refining, by adding aluminum to perform deoxidation and adding ferrotitanium to undergo nitrogen fixation, the content of O and N in the steel can be controlled, and finally by adding ferroboron, the yield of boron and the distribution uniformity of boron in the steel can be guaranteed. Specifically, the heating temperature is at 1120-1180DEG C, and the heating time is 90-120min; the initial rolling temperature of hot rolling is 1090-1150DEG C, and the final rolling temperature is 790-850DEG C; the initial cooling temperature is 750-810DEG C, and the terminal cooling temperature ranges from (500-540)-30DEG C to (500-540)+30DEG C. In the invention, by control of boron in the steel to avoid combination with oxygen and nitrogen, the content of boron in solid solution in the steel can be ensured, and the reinforcement effect of boron can be improved. Through changing the adding amount of boron and adjusting the temperatures of heating, hot rolling and cooling, the low-cost boron-containing steel with strength levels of 460MPa, 500MPa and 550MPa can be obtained.

Description

technical field [0001] The invention belongs to the technical field of metallurgy, and in particular relates to a low-cost boron-containing steel and a manufacturing method thereof. Background technique [0002] As an alloying element added to steel, B has been found to have beneficial effects for a long time. For example, adding 0.001% to 0.002% of B to steel can significantly improve the hardenability of steel, increase the hardenable size of steel, and improve The uniformity of structure and properties in the steel section after quenching; B is also used to improve the high-temperature mechanical properties of some steels, such as high-temperature creep properties and enduring strength. As early as the beginning of the 20th century, attempts to add trace amounts of B to steel began abroad. Domestically, the development of B-containing steel is relatively backward. In the 1980s, China began to study the influence of B on the properties of steel. For example, He Xinlai and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/14C22C33/06C21D8/00

Inventor 郭晓波赵成林王丽娟张维维黄磊高玉明张之胜李文斌李广龙赵坦

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com