Preparation method of high-temperature-resistant neodymium-iron-boron magnetic material

A neodymium-iron-boron, high-temperature-resistant technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of limiting the use range of neodymium-iron-boron magnetic materials and degrading the magnetic properties of neodymium-iron-boron magnetic materials, etc. Achieve the effect of improving remanence, improving magnetic properties and high temperature resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

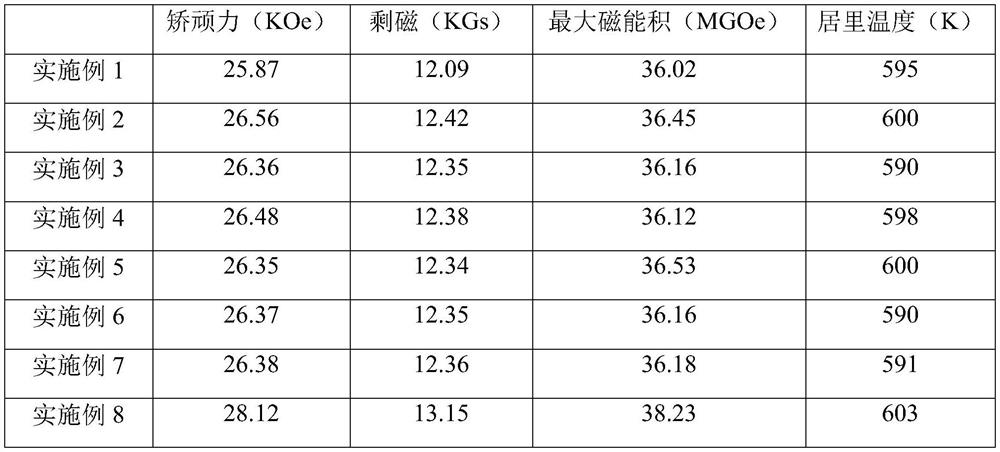

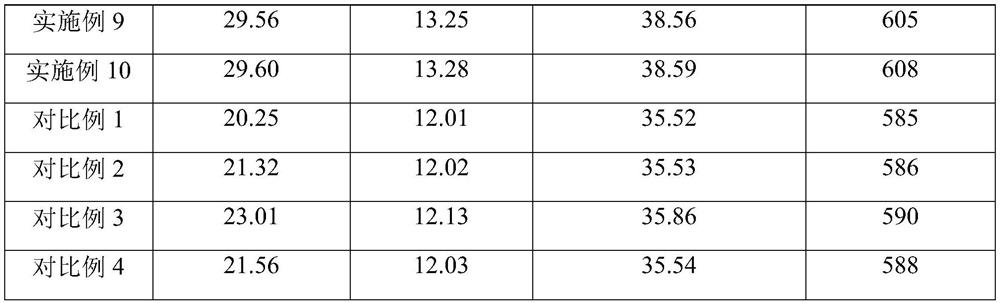

Examples

Embodiment 1

[0043] A high temperature resistant NdFeB magnetic material, comprising the following components: 13wt% praseodymium neodymium, 0.5wt% boron, 15wt% yttrium, 3wt% samarium, 2.5wt% gadolinium, 0.5wt% cobalt, 0.08wt% iridium, 8wt% niobium, 3wt% dysprosium, 10wt% cerium, balance iron and non-removable impurities.

[0044] The preparation method of the above-mentioned NdFeB magnetic material comprises the following steps:

[0045] S1 smelting: put iron niobium block, iron boron block, praseodymium neodymium block, dysprosium iron block, pure iron block, cerium block, iridium block, yttrium block and samarium block into a smelting furnace according to a certain weight ratio for smelting; the obtained molten liquid Pouring on a water-cooled roller for stripping to obtain stripping sheets;

[0046] S2 pulverization: put the thin strip prepared in S1 into the hydrogen breaking furnace, the absolute pressure in the hydrogen breaking furnace is 2Pa, pass hydrogen at room temperature, carr...

Embodiment 2

[0051] A high temperature resistant NdFeB magnetic material, comprising the following components: 15wt% praseodymium neodymium, 0.75wt% boron, 21.5wt% yttrium, 2.5wt% samarium, 4wt% gadolinium, 1wt% cobalt, 0.10wt% iridium, 9wt% niobium, 4wt% dysprosium, 12wt% cerium, balance iron and non-removable impurities.

[0052] The preparation method of the above-mentioned NdFeB magnetic material comprises the following steps:

[0053] S1 smelting: put iron niobium block, iron boron block, praseodymium neodymium block, dysprosium iron block, pure iron block, cerium block, iridium block, yttrium block and samarium block powder into a smelting furnace according to a certain weight ratio for smelting; The liquid is poured on the water-cooled roller for stripping, and the stripping sheet is obtained;

[0054] S2 pulverization: put the thin strip prepared in S1 into the hydrogen breaking furnace, the vacuum degree in the hydrogen breaking furnace is 2Pa, pass hydrogen at room temperature, ...

Embodiment 3

[0059] A high temperature resistant NdFeB magnetic material, comprising the following components: 18wt% praseodymium neodymium, 1wt% boron, 28wt% samarium, 6.5wt% gadolinium, 1.5wt% cobalt, 0.12wt% iridium, 10wt% niobium, 5wt% % dysprosium, 15 wt% cerium, balance iron and non-removable impurities.

[0060] The preparation method of the above-mentioned NdFeB magnetic material comprises the following steps:

[0061] S1 smelting: put iron niobium block, iron boron block, praseodymium neodymium block, dysprosium iron block, pure iron block, cerium block, iridium block, yttrium block and samarium block into a smelting furnace according to a certain weight ratio for smelting; the obtained molten liquid Pouring on a water-cooled roller for stripping to obtain stripping sheets;

[0062] S2 pulverization: put the thin strip prepared in S1 into the hydrogen breaking furnace, the absolute pressure in the hydrogen breaking furnace is 2Pa, pass hydrogen at room temperature, carry out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com