Graphite boat pretreatment method

A graphite boat and pretreatment technology, used in gaseous chemical plating, coatings, electrical components, etc., can solve the problems of increasing pretreatment time, breaking silicon wafers, increasing the cost of graphite boat pretreatment, and reducing pretreatment. time, the effect of reducing the cost of preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present invention provides a graphite boat pretreatment method, which can reduce the pretreatment time and reduce the pretreatment cost of the graphite boat. The details will be described below.

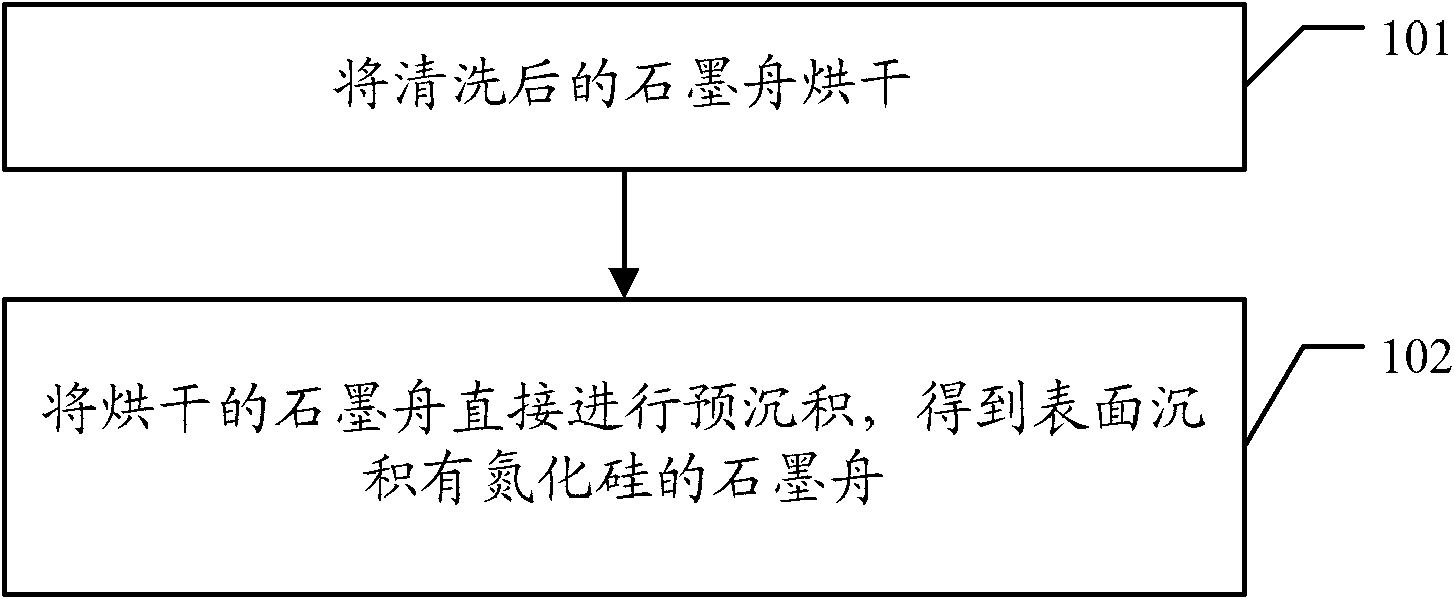

[0024] refer to figure 1 , an embodiment of the graphite boat pretreatment method provided by the embodiments of the present invention includes:

[0025] 101. Dry the cleaned graphite boat.

[0026] The graphite boat is used in the PECVD process of the solar cell manufacturing process. The solar cell is placed in the graphite boat to deposit the silicon nitride film. In order to prevent the graphite boat from absorbing silicon nitride, the graphite boat must first be treated with Pre-deposition, coating the graphite boat with a silicon nitride film;

[0027] In the process of producing solar cells, after the graphite boat is used for a certain number of times, such as 150 times, it needs to be cleaned. Hydrofluoric acid is used during cleaning, which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com