Photosensitive resin composition for color filter and color filter formed thereby

A color filter, photosensitive resin technology, applied in the direction of filter, optics, optomechanical equipment, etc., can solve the problems of poor adhesion, pattern undercut and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A-1

[0090] Synthesis example A-1: Production method of alkali-soluble resin (A-1)

[0091] On a four-necked conical flask with a capacity of 1000 milliliters, a nitrogen inlet, a stirrer, a heater, a condenser tube and a thermometer are arranged, and nitrogen is introduced and the solvent 3-ethoxy ethyl propionate (hereinafter referred to as EEP) 200 parts by weight.

[0092] When the solvent in the four-necked conical flask was stirred, the temperature of the oil bath was raised to 100°C, and then the monomer mixture was mixed as shown in Table 1: 2-methacryloylethoxysuccinate monomer (hereinafter referred to as HOMS) 45 parts by weight, styrene monomer (hereinafter referred to as SM) 40 parts by weight, dicyclopentenyl oxyethyl acrylate (hereinafter referred to as DCPOA) 10 parts by weight and methyl acrylate monomer (hereinafter referred to as MA) 5 parts by weight, Continuously add to the four-necked conical flask, and stir to mix, while raising the oil bath temperature of ...

Embodiment 1

[0098] Use 100 parts by weight (solid content) of alkali-soluble resin (A-1) obtained in the aforementioned synthesis examples, 50 parts by weight of dipentaerythritol hexaacrylate (DPHA, hereinafter referred to as B-2) shown in Table 2, 2-methyl- 1-(4-methylthiophenyl)-2-morpholino-1-propanone (hereinafter referred to as C-1-1) 1 weight part, 1-[9-ethyl-6-(2-methyl Benzoyl)-9H-carbazol-3-yl]-ethanone 1-(O-acetyl oxime) (hereinafter referred to as C-2-1) 3 parts by weight, 4,4'-bis(dimethylamine) di Benzophenone (hereinafter referred to as C-3-1) 6 parts by weight, C.I. Pigment Red 254 (hereinafter referred to as E-1) 20 parts by weight, add solvent ethyl 3-ethoxy propionate (hereinafter referred to as D-1) 500 After the parts by weight are dissolved and mixed with a shaker, the photosensitive resin composition for color filters can be prepared. Table 2 shows the results obtained by measuring the characteristics of the photosensitive resin composition for a color filter by ea...

Embodiment 2 to 16 and comparative example 1 to 6

[0100] Embodiments 2 to 16 and Comparative Examples 1 to 6 use the same operation method as that of the photosensitive resin composition for the color filter of Embodiment 1, the difference is that Embodiments 2 to 16 and Comparative Examples 1 to 6 are The types and amounts of raw materials in the photosensitive resin composition for color filters were changed, and the detailed data and subsequent evaluation results are shown in Table 2 (Examples 1 to 16) and Table 3 (Comparative Examples 1 to 6), respectively.

[0101] Evaluation method

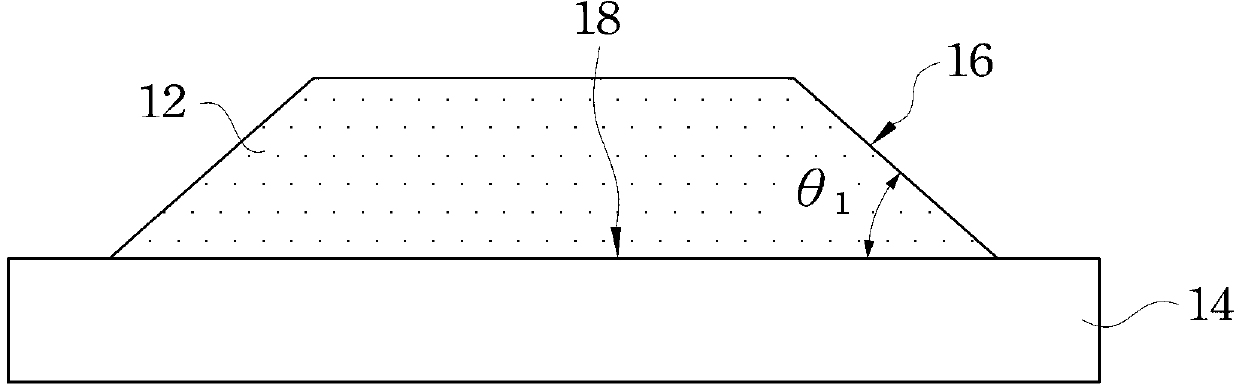

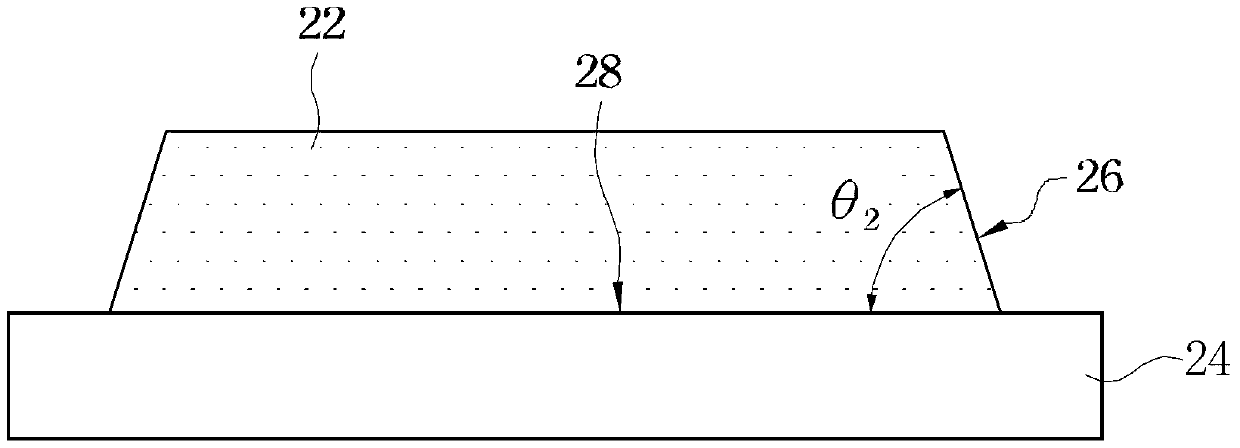

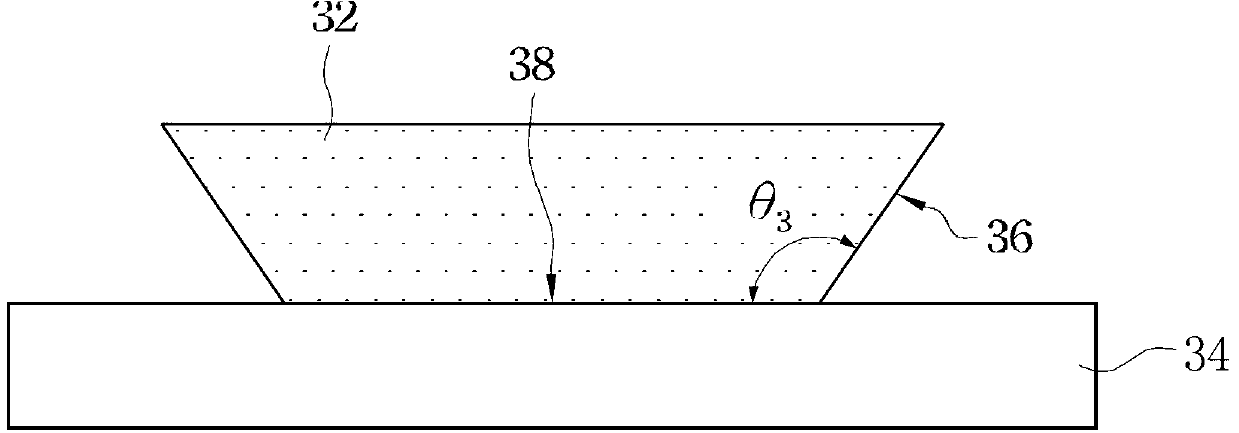

[0102] The aforementioned photosensitive resin composition for color filters and the photosensitive resin layer (or pixel layer) prepared therefrom can perform alkali resistance, undercutting, and adhesion under low-illuminance exposure conditions according to the following steps: , Residue detection to evaluate its effectiveness.

[0103] 1. Alkali resistance:

[0104] Coat the photosensitive resin composition on a 100mm×100mm glass subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com