Silicon substrate niobium nitride film superconducting material and preparing method thereof

A technology of superconducting material and niobium nitride, which is applied in the manufacturing/processing of superconducting devices, superconducting parts, metal material coating process, etc., can solve the problem of reducing the superconducting properties of NbN thin films and the large lattice mismatch of crystal structure. , there are gaps in superconducting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background technology, the existing Si-based NbN thin-film superconducting materials still lack suitable transition layer materials, and it is impossible to obtain thin-film superconducting materials with good lattice matching between Si crystal and NbN layer and excellent superconducting properties. To a certain extent, the application field of Si-based NbN thin film superconducting materials is limited.

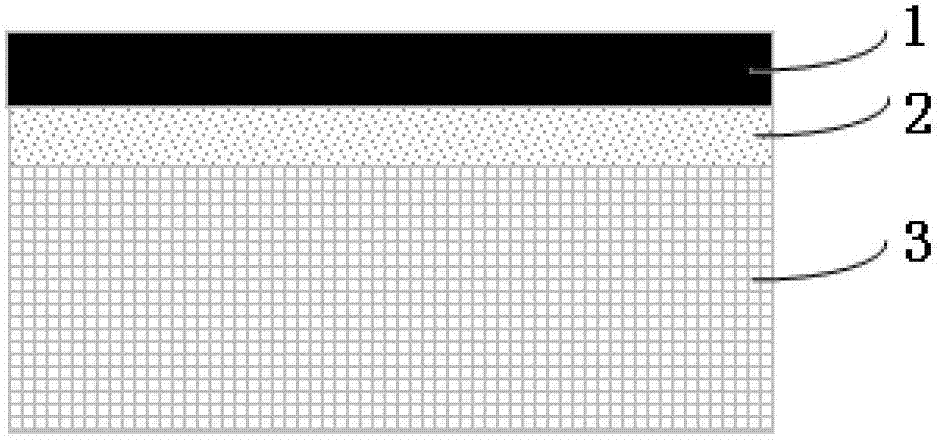

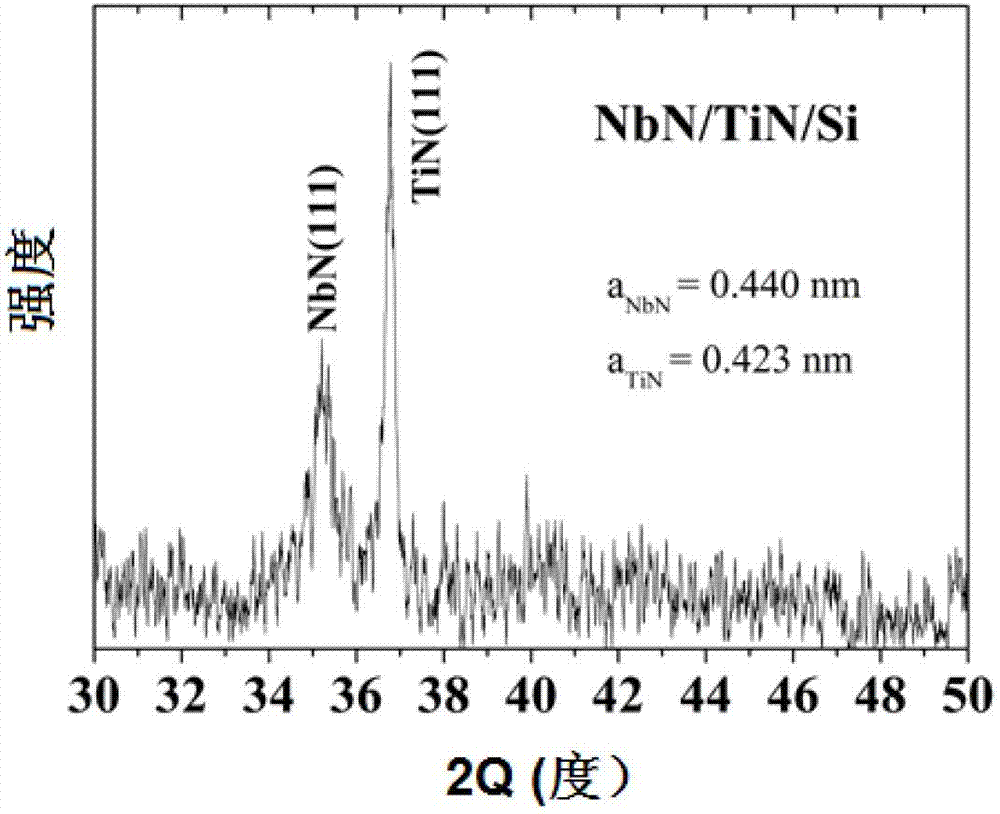

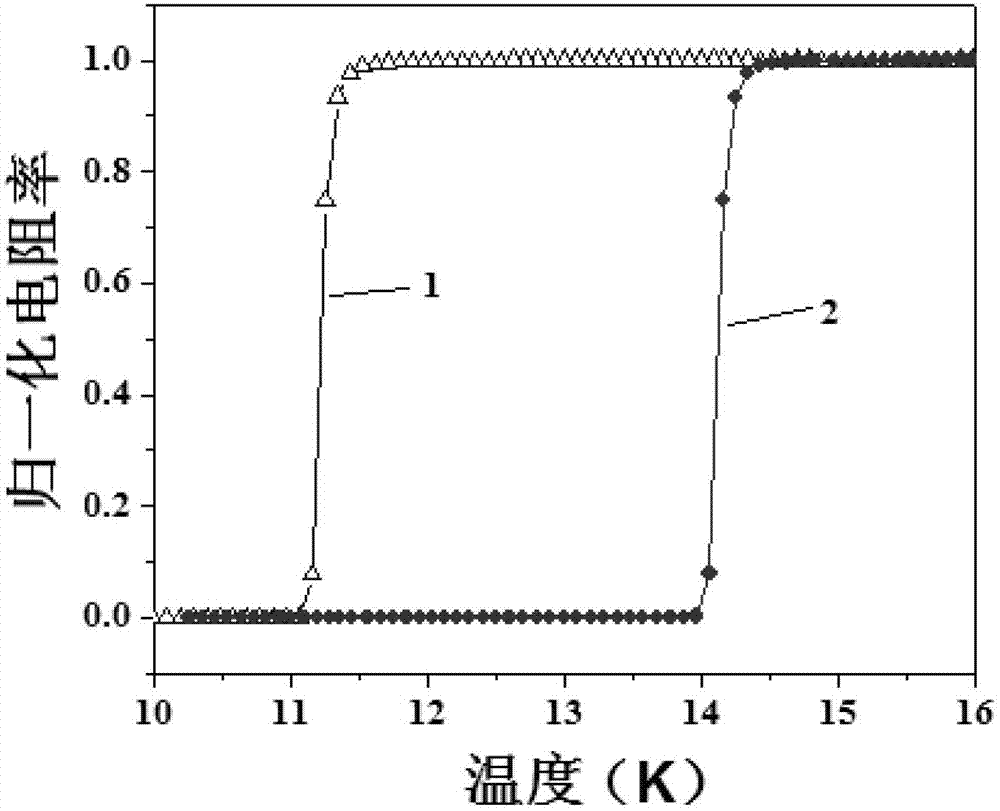

[0029] Therefore, the present invention proposes a new Si-based NbN thin film superconducting material. The Si-based NbN thin film superconducting material uses TiN as a transition layer. Since TiN and NbN both belong to the face-centered cubic structure, and the lattice mismatch is small, Therefore, the use of the TiN transition layer greatly reduces the thickness of the interfacial distortion layer in the NbN film, while the crystallinity of NbN is improved; and NbTiN itself is a T c For higher superconducting materials, even if the two elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com