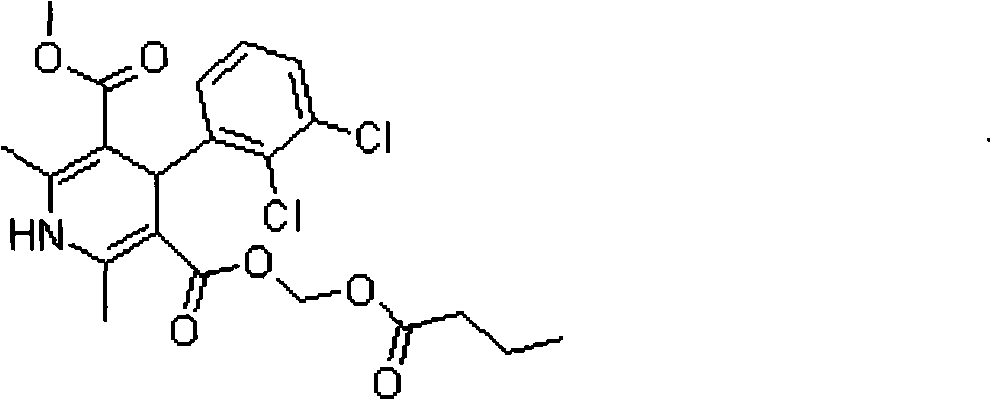

Clevidipine butyrate freeze-dried emulsion

A technology of clevidipine butyrate and freeze-dried emulsion, which is applied in the field of clevidipine butyrate freeze-dried emulsion, can solve the problems of particle aggregation increase, harm, fat emulsion instability, etc., and achieve low toxic and side effects, high curative effect, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

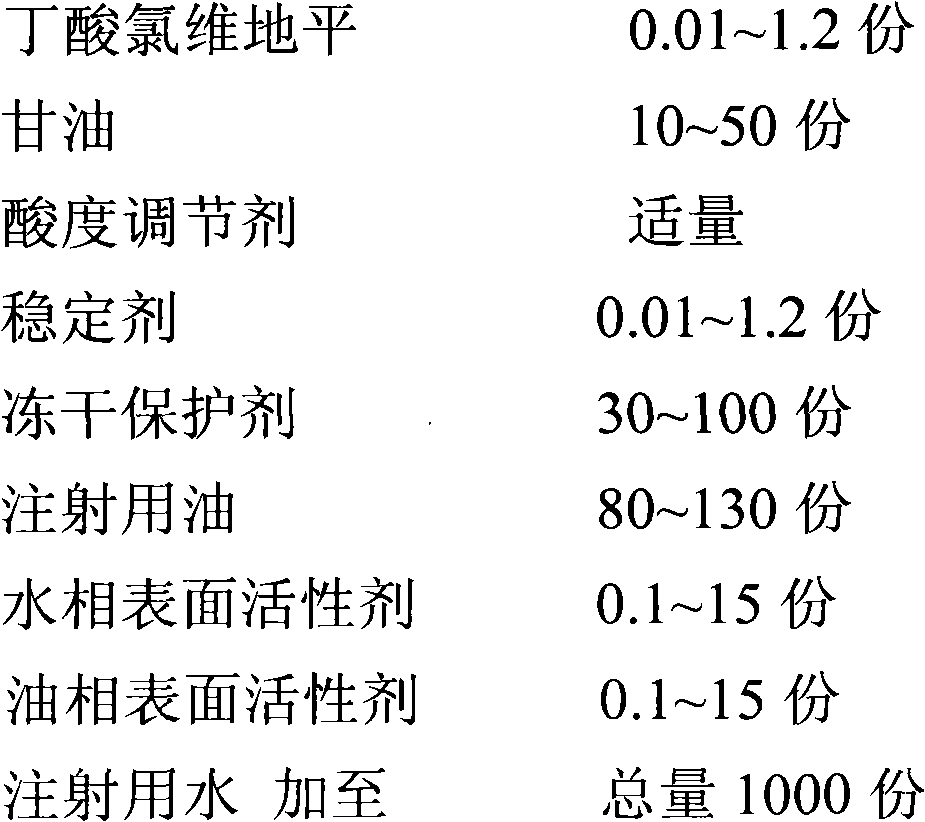

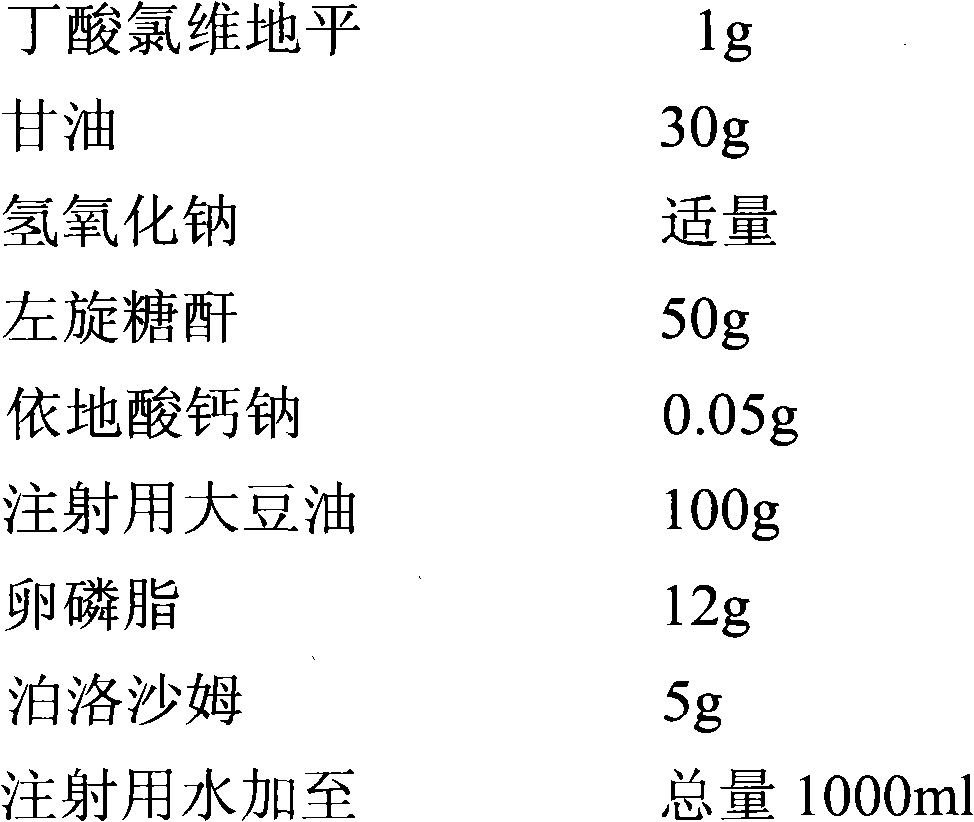

[0036] prescription:

[0037]

[0038] Preparation:

[0039] Add glycerin, poloxamer, dextran, and calcium sodium edetate into 300ml of water for injection, dissolve, add sodium hydroxide to adjust the pH to 6.0-7.0, boil for 15 minutes, fill with nitrogen, cool and keep warm to 50°C.

[0040] Heat soybean oil for injection to 60°C, dissolve lecithin and clevidipine butyrate in soybean oil for injection under high shear at 7000rpm, keep warm at 50°C, and continuously fill with nitrogen during the preparation of the oil phase.

[0041] The water phase and the oil phase were sheared and mixed evenly, supplemented with water for injection to the formula quantity, and the high-pressure homogenization pressure was 700 bar, and homogenized until a fat emulsion with a particle size of less than 220nm was obtained.

[0042] Pass the above-mentioned fat emulsion through a 0.22 μm filter, filter and sterilize, fill in vials, place the filled and semi-stoppered semi-finished product ...

preparation Embodiment 2

[0044] prescription:

[0045]

[0046]

[0047] Preparation:

[0048] Add glycerin, sodium oleate, and sodium bisulfite to 300ml of water for injection, dissolve, add sodium hydroxide to adjust the pH to 8.0-9.0, boil for 15 minutes, fill with nitrogen, cool and keep warm to 55°C.

[0049] Heat soybean oil and medium-chain triglycerides for injection to 60°C, dissolve cholesterol and clevidipine butyrate in soybean oil and medium-chain triglycerides for injection under high shear at 8000rpm, and keep warm at 50°C , continuous nitrogen filling during oil phase preparation.

[0050] The water phase and the oil phase were sheared and mixed evenly, supplemented with water for injection to the formula amount, and the pressure of high-pressure homogenization was 600 bar, and homogenized until a fat emulsion with a particle size of less than 220nm was obtained, and lactose was added and stirred to dissolve.

[0051] Pass the above-mentioned fat emulsion through a 0.22 μm filt...

preparation Embodiment 3

[0053] prescription:

[0054]

[0055]

[0056] Preparation:

[0057]Add glycerin, poloxamer, mannitol, and vitamin C into 300ml of water for injection, dissolve, add sodium hydroxide to adjust the pH to 6.0-7.0, boil for 15 minutes, fill with nitrogen, cool and keep warm to 50°C.

[0058] Heat soybean oil for injection to 60°C, dissolve lecithin and clevidipine butyrate in soybean oil for injection under high shear at 7000rpm, keep warm at 50°C, and continuously fill with nitrogen during the preparation of the oil phase.

[0059] The water phase and the oil phase were sheared and mixed evenly, supplemented with water for injection to the formula quantity, and the high-pressure homogenization pressure was 700 bar, and homogenized until a fat emulsion with a particle size of less than 220nm was obtained.

[0060] Pass the above-mentioned fat emulsion through a 0.22 μm filter, filter and sterilize, fill in vials, place the filled and semi-stoppered semi-finished product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com