Deflector-type micro-capsule suspension type fluidized bed bioreactor for artificial liver

A bioreactor and flow-through microtechnology, which is applied in the field of biomedicine, can solve the problems of increased microcapsule fragmentation rate, limited fluid shear force, and inability to guarantee the biological safety of the treatment process, so as to improve purification efficiency and purification efficiency. , to ensure the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

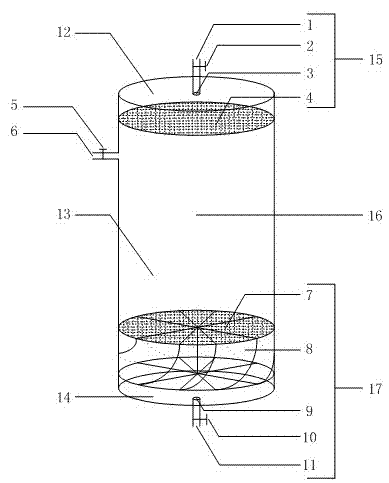

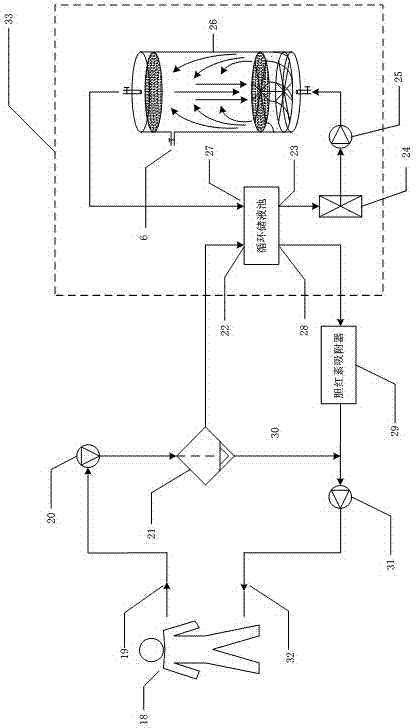

[0023] Such as figure 2 As shown, the flow-guiding microcapsule suspension fluidized bed bioreactor for the artificial liver of the present invention is the core component of the biological cycle 33 in the biological artificial liver system. Now with figure 2 Taking the simple biological artificial liver treatment mode as an example, the specific implementation scheme of the present invention is introduced.

[0024] Treatment preparation, open the valve 5, pour the microcapsule-coated hepatocytes into the cylindrical inner cavity of the main body part 16 of the reactor through the sampling and microcapsule perfusion port 6, close the perfusion port valve after the microcapsule perfusion is completed, and inject the hepatic cells from the liquid inlet 11 Slowly preflush the prepared circulating buffer. Remove all air bubbles from the circulation lines and check the system for tightness. At this time, since the pore size of the inlet filter screen is smaller than the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com