Metal pipe butt-joint circumferential seam heating device

A heating device, butt ring technology, applied in metal processing equipment, auxiliary devices, furnace types, etc., can solve the problems of uneven heating of the heated metal pipe wall, lack of temperature measurement, monitoring, and low energy utilization efficiency, reducing The effect of human factor interference, improving energy efficiency and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

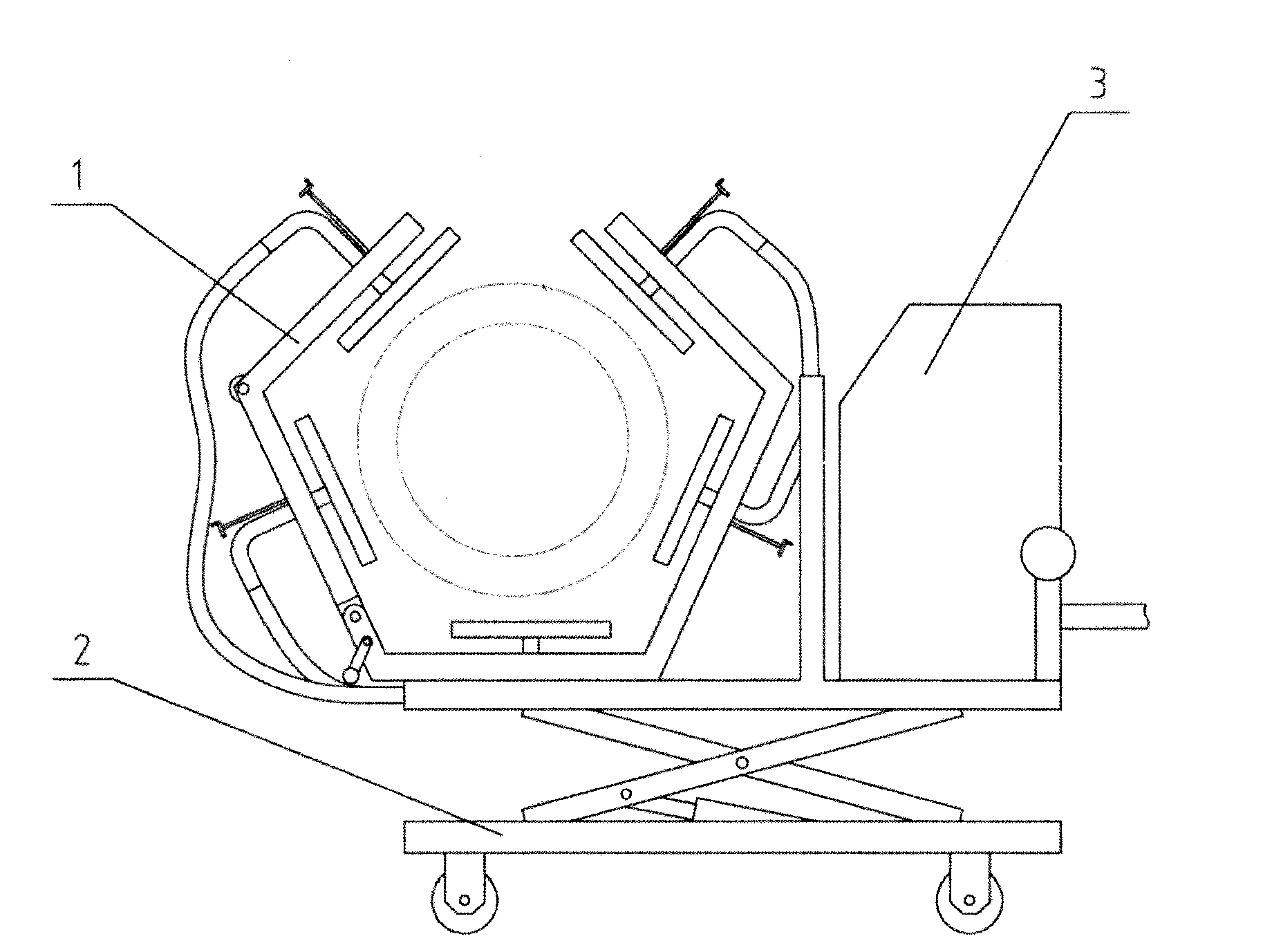

[0023] Such as figure 1 As shown, the heating device for the butt circular seam of metal pipes provided in this embodiment includes a ring-shaped heating ring 1 , a height-adjustable frame 2 and a control unit 3 . The heating ring 1 and the control unit 3 are installed on the frame 2 through methods such as lines / pipelines / threads / welding.

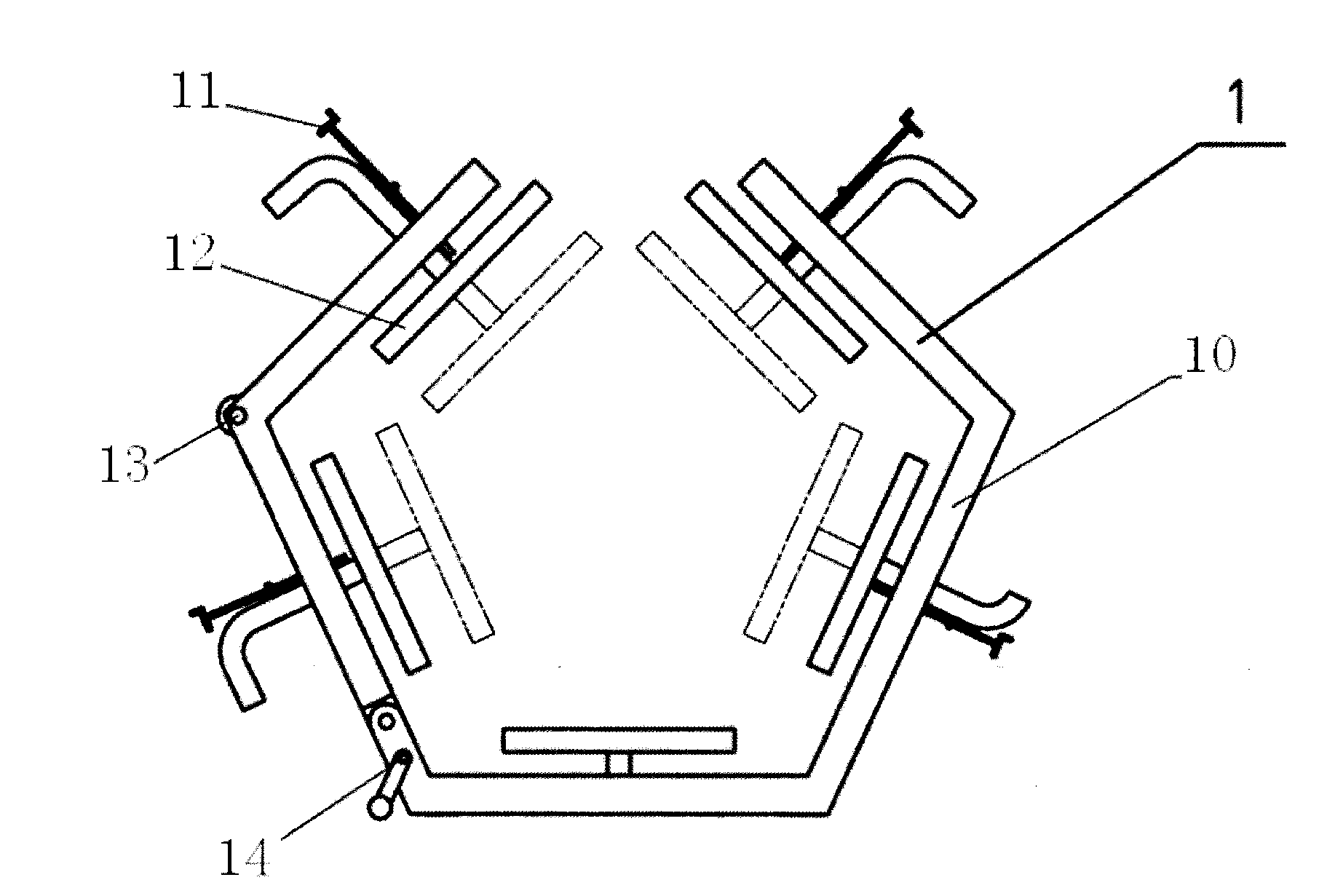

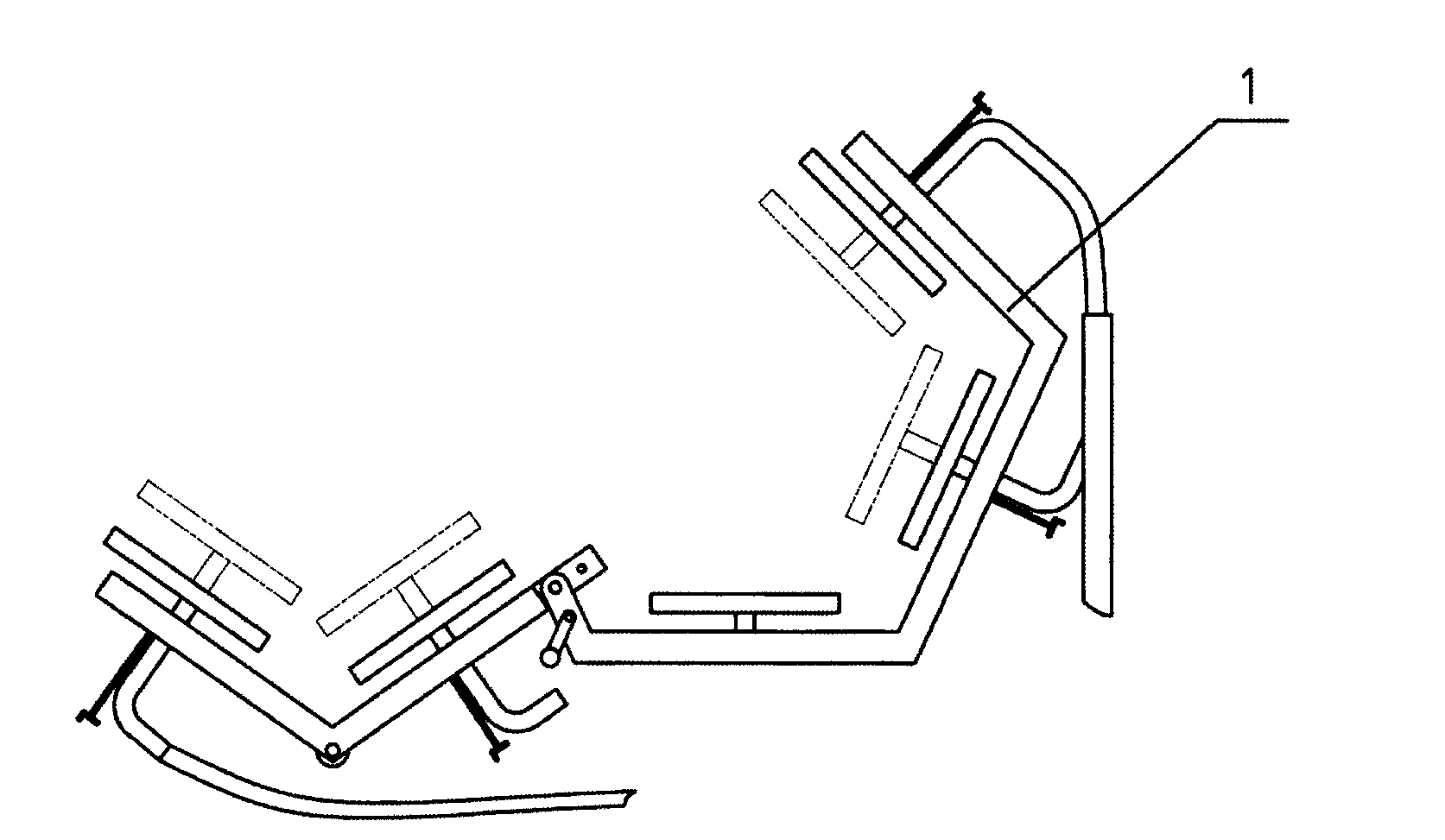

[0024] to combine figure 2 , the heating ring structure 1 carries out 360°circular uniform heating of the metal pipe in the non-rotating state, which is mainly composed of a ring frame 10, a swivel 11, a metal fiber heating plate 12, a roller 13 and a position locking handle 14, etc. . Ring frame 10 comprises left half ring frame and right half ring frame, is connected by pin shaft between left half ring frame and right half ring frame, makes left half ring frame can turn over, as image 3 As shown, after flipping in place, the flip angle is 140°. After the left half ring frame is turned inwards into place, it is locked by the positio...

Embodiment 2

[0032] Such as Image 6 As shown, another metal pipe butt circular seam heating device provided in this embodiment includes a frame 2 , a control unit 3 and a heating block 4 . The heating block 4 and the control unit 3 are installed on the frame 2 through methods such as lines / pipelines / threads / welding.

[0033] The two heating blocks 4 are arranged at an angle, one of the heating blocks 4 is designed as a fixed connection, and the other heating block 4 is designed as a pin connection and can be turned down. The range of the angle a between the two heating blocks 4 is: 70°~150°. The arc-shaped angle plate 41 with through holes at different positions is fixed on the fixed heating block 4, the middle part of the angle adjustment rod 42 is hinged and fixed, the inner side of one end extends into the through hole, and an operating handle is arranged on the outer side 43, the other end is connected and fixed with another heating block 4. The heating block 4 adopts the same meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com