Low frequency strong magnetic field shield material

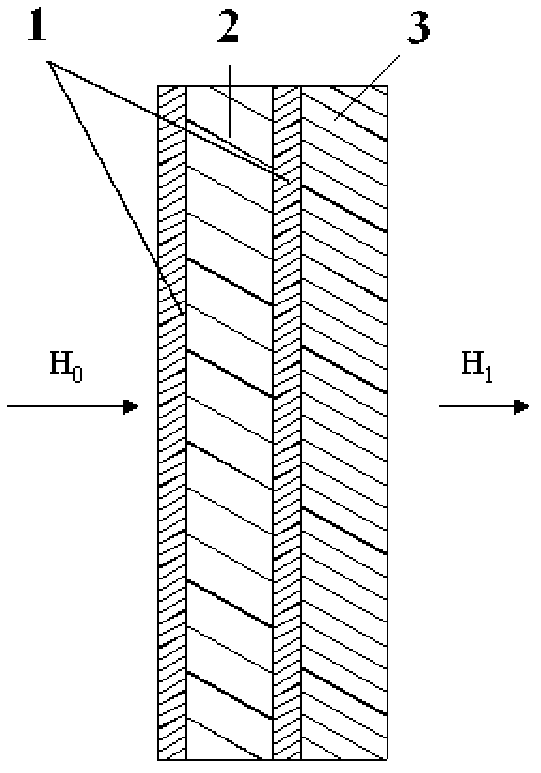

A shielding material and strong magnetic field technology, applied in the fields of magnetic/electric field shielding, electrical components, layered products, etc., can solve the problems of difficult shielding, reduced shielding efficiency, and unsatisfactory shielding effect of low-impedance magnetic field waves, and achieves improved anti-low frequency The ability of strong magnetic field interference and the effect of improving shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

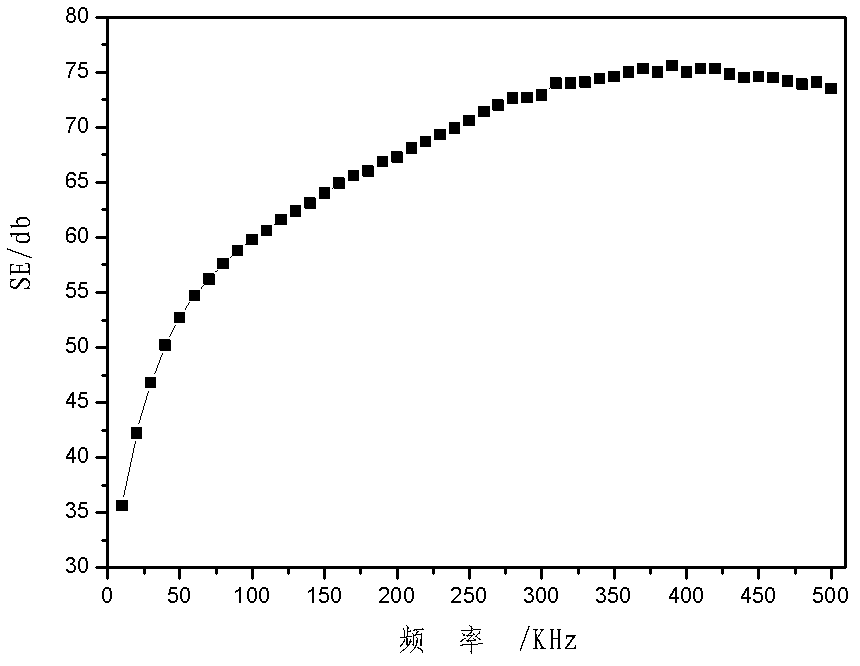

[0036] First prepare a PVA cylindrical tube according to the technical scheme described in the summary of the invention, then coat the outer wall with a layer of 0.1mm thick 1J85 ferromagnetic strip, and finally coat the outermost layer of the test sample with a layer of aluminum foil with a thickness of 0.03mm. The heat treatment process of ferromagnetic materials is: vacuum atmosphere, heat treatment temperature 1180°C, heat preservation for 4 hours, then cooling to 600°C in 3 hours, filling with argon gas at a cooling rate of 500°C / h to quickly cool to 150°C out of the furnace. Put the sample in a uniform magnetic field to test its shielding performance. The frequency of the magnetic field ranges from 10KHz to 500KHz, and the magnetic field strength ranges from 2.3Gs to 0.3Gs. Test results such as figure 2 As shown, the shielding effectiveness of the material is less than 40dB at 10KHz, and greater than 40dB above 20KHz.

Embodiment 2

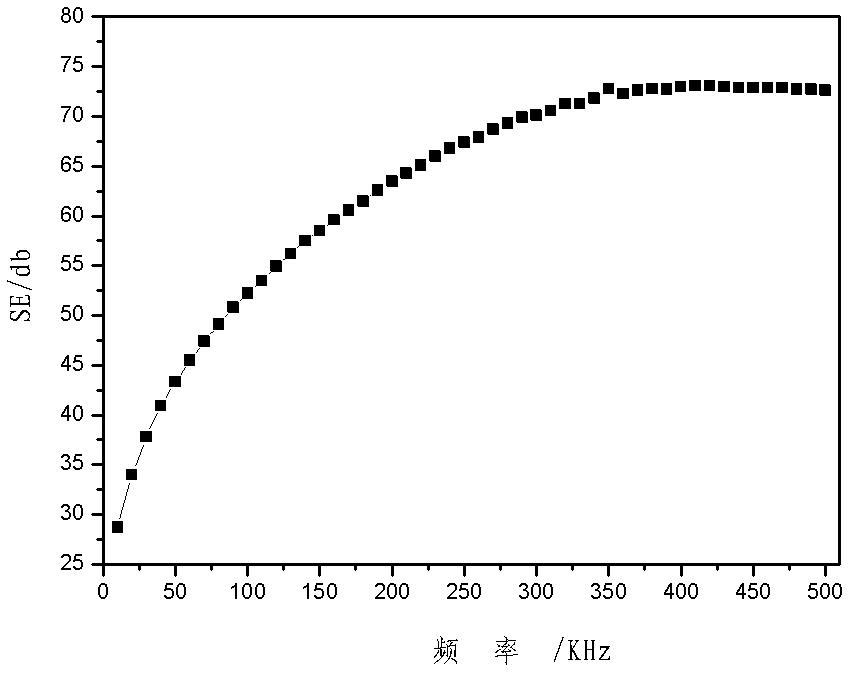

[0038] First, prepare a PVA cylindrical tube according to the technical scheme described in the summary of the invention, then coat the outer wall with a layer of 1J50 ferromagnetic strip with a thickness of 0.1mm, and finally coat the outermost layer of the test sample with a layer of aluminum foil with a thickness of 0.03mm. The heat treatment process of ferromagnetic materials is: vacuum atmosphere, heat treatment temperature 1150°C, heat preservation for 5 hours, then cooling to 600°C in 3 hours, filling with argon gas at a cooling rate of 400°C / h to quickly cool to 150°C out of the furnace. Put the sample in a uniform magnetic field to test its shielding performance. The frequency of the magnetic field ranges from 10KHz to 500KHz, and the magnetic field strength ranges from 2.3Gs to 0.3Gs. Test results such as image 3 As shown, the shielding effectiveness of the material is less than 40dB at 10KHz-30KHz, and greater than 40dB above 40KHz.

Embodiment 3

[0040]First prepare the PVA cylindrical tube according to the technical scheme described in the summary of the invention, then respectively paste a layer of 0.05mm thick 1J79 and 0.1mm thick 1J50 ferromagnetic strips on the outer wall, and finally between the ferromagnetic strips and between the test samples The outermost layer is covered with a layer of aluminum foil with a thickness of 0.03mm. The heat treatment process of 1J79 ferromagnetic material is: vacuum atmosphere, heat treatment temperature 1180°C, heat preservation for 4 hours, then cooling to 600°C in 3 hours, filling with argon gas at a cooling rate of 500°C / h to quickly cool to 150°C out of the furnace. The heat treatment process of 1J50 ferromagnetic material is: vacuum atmosphere, heat treatment temperature 1150°C, heat preservation for 5 hours, then cooling to 600°C in 3 hours, filling with argon gas at a cooling rate of 400°C / h to quickly cool to 150°C out of the furnace. Put the sample in a uniform magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com