Preparation method of rod-shaped AgBr nanometer material

A nanomaterial and rod-shaped technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of less preparation, and achieve the effect of simple operation, high output and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

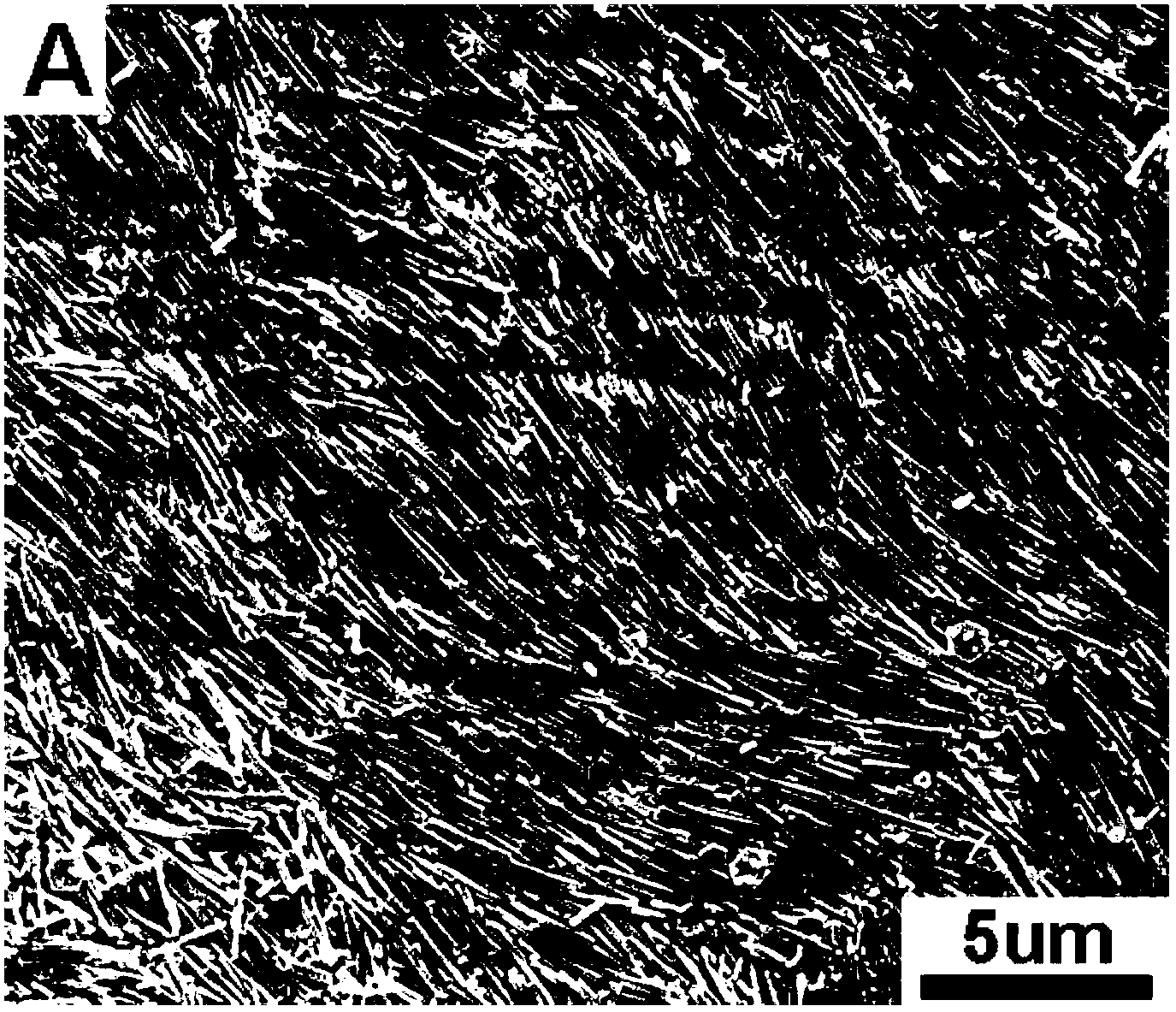

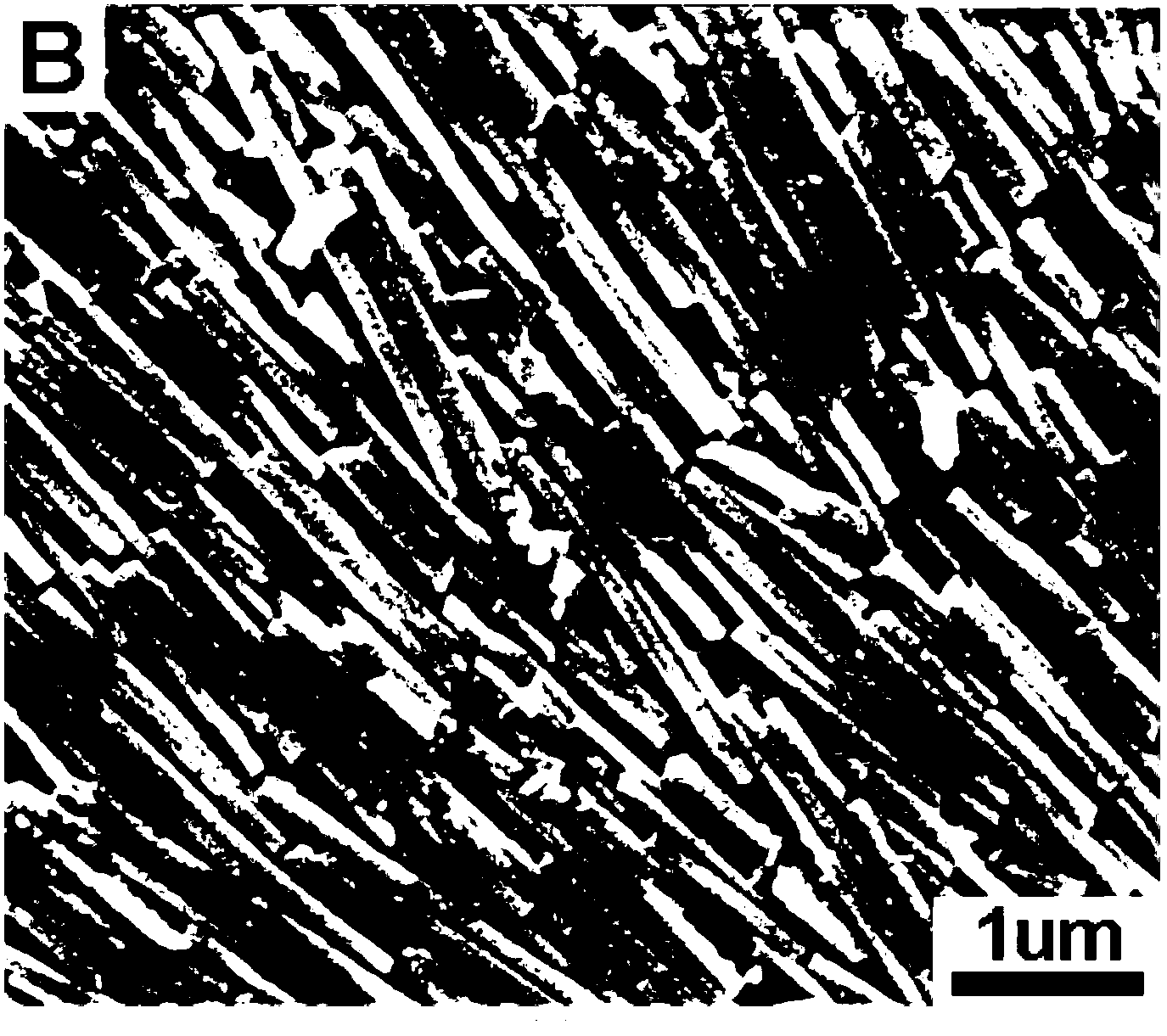

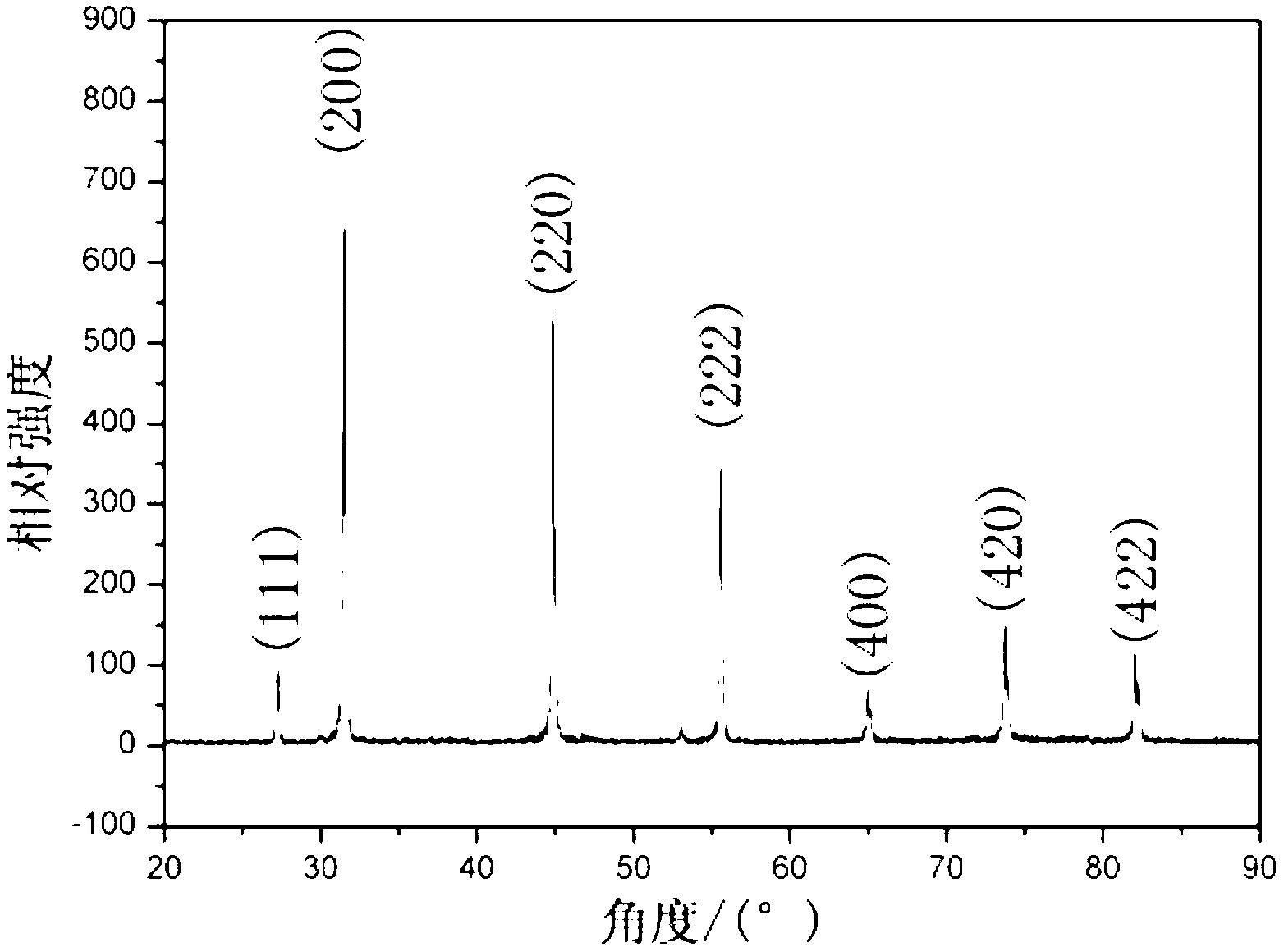

[0017] Adopt the method provided by the invention to prepare rod-shaped AgBr nanometer material, concrete steps are as follows:

[0018] In the first step, 54mg of PVP (MW 5800) and 45mg of sodium bromide were dissolved in a mixed solvent of dimethyl sulfoxide / deionized water (30mL, 10 / 20, V / V) at room temperature to obtain a colorless and transparent solution ,

[0019] In the second step, the colorless transparent solution was stirred at 60° C. for 30 minutes, and then 10 mL of silver acetate aqueous solution of 5 mg / mL was slowly added dropwise thereto, and the solution gradually became light yellow, and kept stirring at 60° C. for 30 minutes.

[0020] In the third step, the light yellow solution obtained was put into a 45mL polytetrafluoroethylene-lined stainless steel reactor, and subjected to hydrothermal reaction at 130° C. in an oven for 12 hours, and the system was naturally cooled to obtain a yellow precipitate.

[0021] The fourth step is to use a centrifuge to sep...

Embodiment 2

[0024] In the first step, 54mg of PVP (MW5800) and 45mg of sodium bromide were dissolved in a mixed solvent of dimethyl sulfoxide / deionized water (30mL, 10 / 20, V / V) at room temperature to obtain a colorless and transparent solution.

[0025] In the second step, the colorless transparent solution was stirred at 60° C. for 30 minutes, and then 10 mL of silver acetate aqueous solution of 5 mg / mL was slowly added dropwise thereto, and the solution gradually became light yellow, and kept stirring at 60° C. for 30 minutes.

[0026] In the third step, the light yellow solution obtained was put into a 45mL polytetrafluoroethylene-lined stainless steel reactor, and subjected to a hydrothermal reaction at 130° C. in an oven for 2 hours, and the system was naturally cooled to obtain a yellow product.

[0027] The fourth step is to use a centrifuge to separate the yellow product from the solution, wash the yellow product with deionized water first, and then wash it with absolute ethanol. ...

Embodiment 3

[0029] Adopt the method provided by the invention to prepare rod-shaped AgBr nanometer material, concrete steps are as follows:

[0030] In the first step, 50 mg of PVP (MW 5800) and 45 mg of sodium bromide were dissolved in a mixed solvent of dimethyl sulfoxide / deionized water (30 mL, 10 / 20, V / V) at room temperature to obtain a colorless and transparent solution ,

[0031] In the second step, the colorless transparent solution was stirred at 60° C. for 30 minutes, then slowly added dropwise to 8 mL of silver acetate aqueous solution of 5 mg / mL, the solution gradually became light yellow, and kept stirring at 60° C. for 30 minutes.

[0032] In the third step, the light yellow solution obtained was put into a 45mL polytetrafluoroethylene-lined stainless steel reactor, and subjected to hydrothermal reaction at 130° C. in an oven for 10 hours, and the system was naturally cooled to obtain a yellow precipitate.

[0033] The fourth step is to use a centrifuge to separate the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com