Combustion improver and fuel made of same as well as fuel production method and application

A combustion-supporting agent and fuel technology, which is applied in the field of low-quality coal composite catalytic combustion-supporting agents, can solve the problems of equipment corrosion, seriousness, and high cost of catalytic combustion-supporting agents, and achieve the effect of no secondary pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

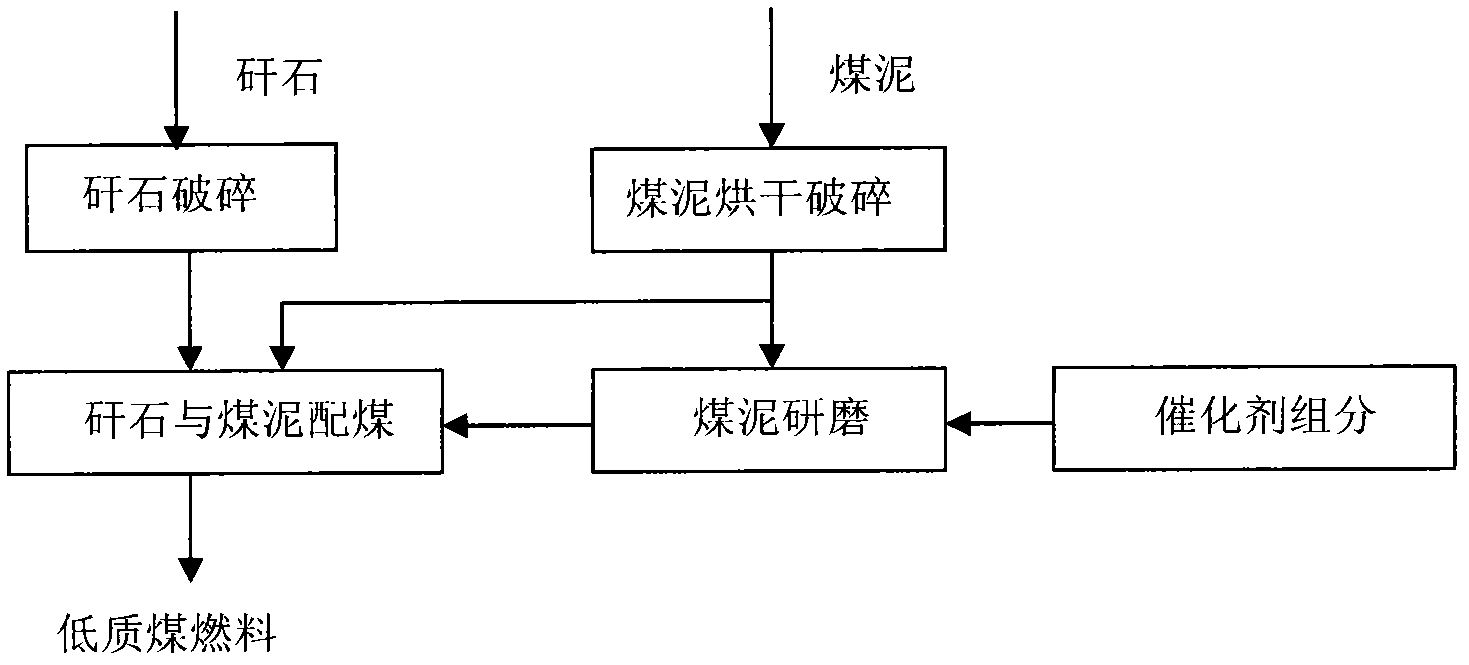

[0028] The present invention also provides a kind of fuel, and its this fuel is mainly formed by mixing dispersoid and coal blending, wherein the proportion of sodium humate is 0.5-2%, the proportion of potassium nitrate is 0.2-1%, and the proportion of citric acid is 0.5-2%, the proportion of sodium acetate is 0.2-1.5%, and the proportion of sodium dodecylbenzenesulfonate is 0.2-1.5%. The proportion of dispersant is 5-20% of each coal blending. The preparation method of this fuel comprises the following steps:

[0029] Step 1, weigh a certain amount of sodium humate, potassium nitrate, citric acid, sodium acetate, sodium dodecylbenzenesulfonate in proportion, wherein the proportion of sodium humate is 0.2-2%, and the proportion of potassium nitrate is 0.2% -1.5%, the proportion of citric acid is 0.5-2%, the proportion of sodium acetate is 0.2-1.5%, and the proportion of sodium dodecylbenzenesulfonate is 0.2-1.5%. The proportion of dispersant is 5-20% of each coal blending. ...

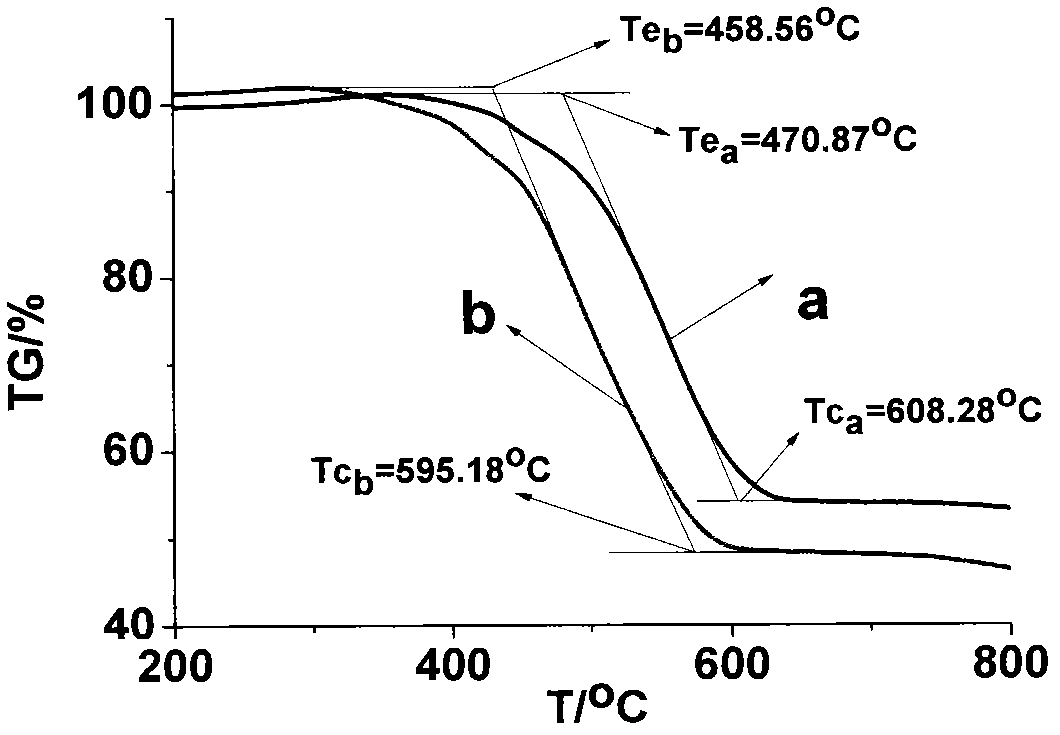

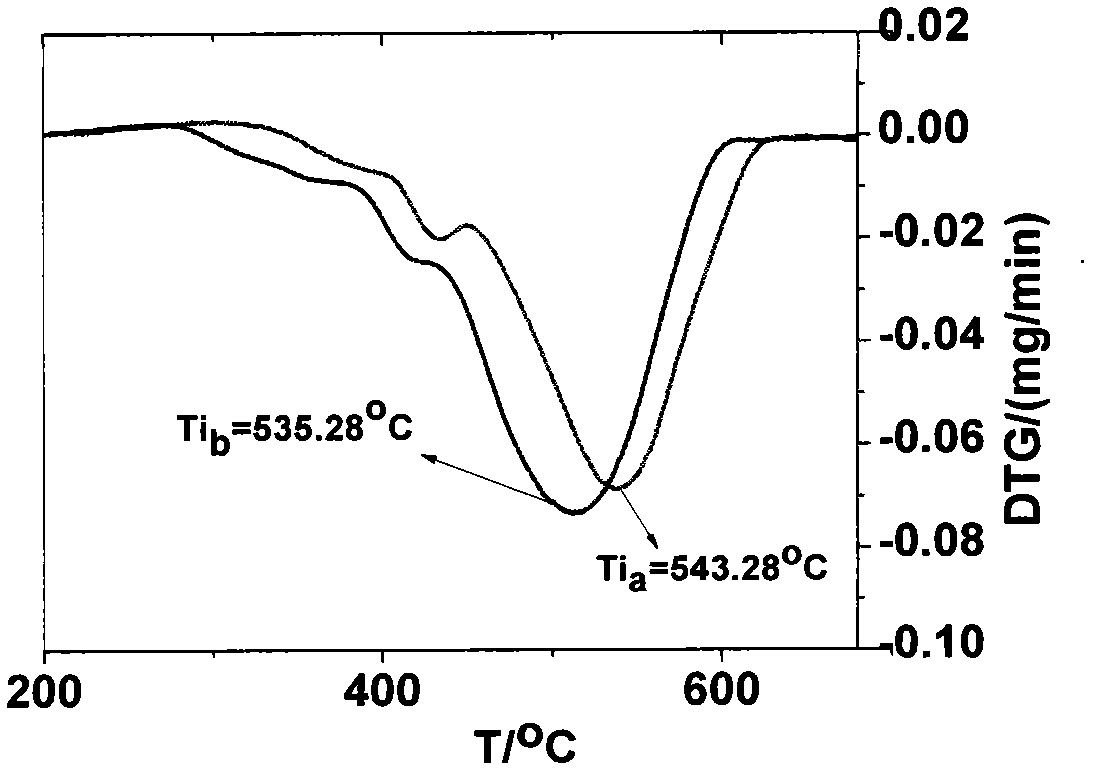

Embodiment 1

[0035] Embodiment 1, utilize 5% coal slime as dispersant, the component of catalytic combustion accelerant, potassium nitrate 0.2%, sodium humate 0.2%, citric acid 0.5%, sodium acetate 0.2%, dodecylbenzenesulfonic acid Add 0.2% sodium to the dispersoid, grind it to below 120 mesh, then add the dispersoid to the remaining 95% of the coal blending and mix evenly, then it can be used as the fuel for the circulating fluidized bed boiler. At this time, the ignition temperature of the fuel is 464.54°C, and the temperature at the point of maximum weight loss rate is 541.38°C.

example 2

[0036] Example 2, utilizing 10% coal slime as a dispersoid, the components of the catalytic combustion aid, potassium nitrate 0.2%, sodium humate 2%, citric acid 2%, sodium acetate 1.5%, sodium dodecylbenzenesulfonate Add 1.5% to the dispersate, grind it to below 120 mesh, then add the dispersate to the remaining 95% of the coal blending and mix evenly, then it can be used as the fuel for the circulating fluidized bed boiler. At this time, the ignition temperature of the fuel is 467.06°C, and the temperature at the point of maximum weight loss rate is 537.4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com