Method for regenerating aluminum alloy with target ingredient from scrap aluminum

A technology of target components, waste miscellaneous aluminum, applied in the direction of improving process efficiency, etc., can solve problems such as no pollution-free pretreatment, low recovery rate, environmental pollution, etc., achieve significant economic and environmental benefits, and be easy to industrialize. Production, the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

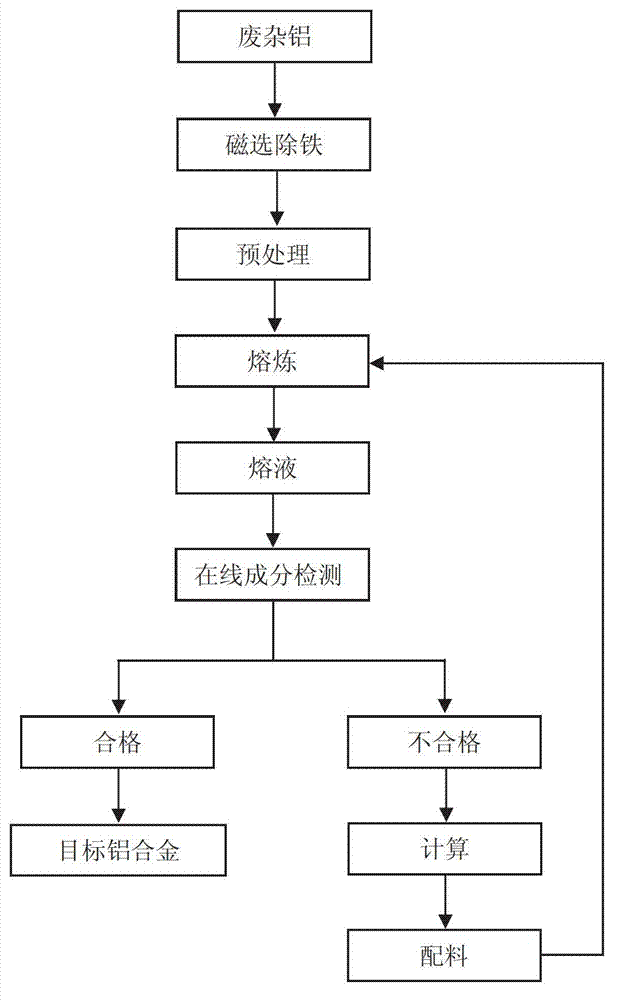

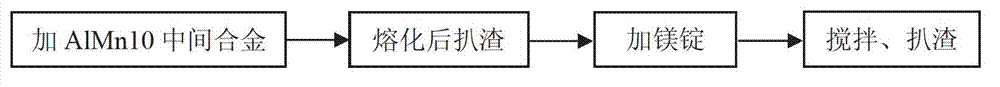

[0049] The recycled scrap aluminum is made into standard 3104 aluminum alloy for pop cans.

[0050] (1) Magnetic separation and iron removal: Magnetic separation removes ferromagnetic materials in waste aluminum;

[0051] (2) Pretreatment: adopt the low-temperature distillation process with a drying temperature of 60°C for 3.0h and 120°C for 3.0h to remove moisture and grease in waste aluminum; use oxygen partial pressure ≦ 10% for organic matter on the surface of waste aluminum at a temperature of Process vibration removal at 600°C for 15 minutes;

[0052] (3) Melting: Swirl suction type submerged melting is adopted, and the melting temperature is controlled at 700°C;

[0053] (4) On-line component detection: take a small amount of fully stirred aluminum liquid, and use a direct reading spectrometer ARL3460 for component detection. Table 2 shows the composition of 3104 aluminum alloy specified in "GB / T3190-2008 Chemical Composition of Deformed Aluminum and Aluminum Alloy", ...

Embodiment 2

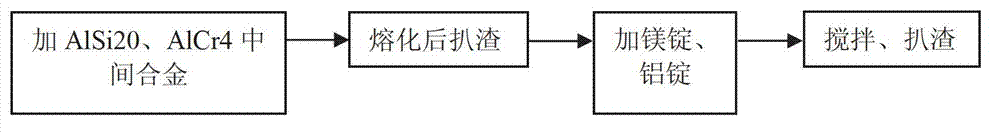

[0081] The recycled scrap aluminum is made into standard 6061 aluminum alloy for automobiles.

[0082] (1) Magnetic separation and iron removal: Magnetic separation removes ferromagnetic materials in waste aluminum;

[0083] (2) Pretreatment: adopt the low-temperature distillation process with a drying temperature of 90°C for 2.0 hours and a drying time of 180°C for 2.0 hours to remove moisture and grease in waste aluminum; use oxygen partial pressure ≦ 10% for organic matter on the surface of waste aluminum and a temperature of Process vibration removal at 550°C for 30 minutes;

[0084] (3) Melting: Press-in type submerged melting is adopted, and the melting temperature is controlled at 750°C;

[0085] (4) On-line component detection: take a small amount of fully stirred aluminum liquid, and use a direct reading spectrometer ARL3460 for component detection. Table 5 shows the composition of the 6061 aluminum alloy stipulated in "GB / T3190-2008 Chemical Composition of Deformed...

Embodiment 3

[0118] The recycled scrap aluminum is made into an aluminum alloy with the composition of cast aluminum ZL105 (ZAlSi5Cu1Mg).

[0119] (1) Magnetic separation and iron removal: Magnetic separation removes ferromagnetic materials in waste aluminum;

[0120] (2) Pretreatment: take drying temperature 100 ℃, time 1.5h and 200 ℃, 1.5h low-temperature distillation process to remove moisture and grease in waste aluminum; use oxygen partial pressure ≦ 10% for organic matter on the surface of waste aluminum, and the temperature is Process vibration removal at 500°C for 45 minutes;

[0121] (3) Melting: vortex type submerged melting is adopted, and the melting temperature is controlled at 800°C;

[0122] (4) On-line component detection: take a small amount of fully stirred aluminum liquid, and use a direct reading spectrometer ARL3460 for component detection. Table 8 shows the composition of the ZAlSi5Cu1Mg aluminum alloy specified in "GB / T1173-1995 Casting Aluminum Alloy", the composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com