Biocompatible fiber composite non-woven net felt and preparation method and application thereof

A fiber composite and biocompatible technology, which is applied in textiles and papermaking, human tubular structure devices, blood vessels, etc., can solve the problems of regenerative stenosis, affecting the patency rate of blood vessels, and reducing the patency rate of vascular grafts. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

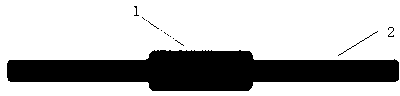

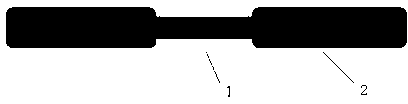

Image

Examples

Embodiment 1

[0082] Polyurethane (PU) was dissolved in hexafluoroisopropanol at a ratio of 12 wt%, and polycaprolactone (PCL) was dissolved in a 3:1 mixture of dichloromethane / dimethylformamide at a ratio of 25 wt%. in solvent. In order to visually distinguish fibers of two different materials, a fluorescent carbocyanine dye was added to the polyurethane solution, and a green fluorescent dye was added to the polycaprolactone solution, both of which had a concentration of 0.03 mg / ml. Firstly, the polyurethane solution containing fluorescent carbocyanine dye was added to a syringe with a 23-gauge metering needle, pumped at a rate of 0.015 ml / min to 0.020 ml / min, and a voltage of 8 kV was applied to the needle tip to start electrospinning. use Figure 6The PU nanofiber layer was collected on the collection area shown, and then the PU nanofiber layer was stretched, and then the polycaprolactone solution containing green fluorescent dye was added to a syringe with a metering needle of 23, at 0...

Embodiment 2

[0086] By changing the ratio of elastic fiber and non-elastic fiber in the preparation process of fiber composite nonwoven mesh, the influence of different ratios on the mechanical properties of fiber composite nonwoven mesh was compared.

[0087] The elastic polymer molded by elastic nanofibers, the nonelastic polymer molded with nonelastic nanomaterials, and the preparation method of elastic nanofiber layer and nonelastic nanofiber layer are the same as in Example 1, that is, the elastic polymer used is the same as in Example 1. The PU described in 1, the non-elastic polymer is the PCL described in embodiment 1.

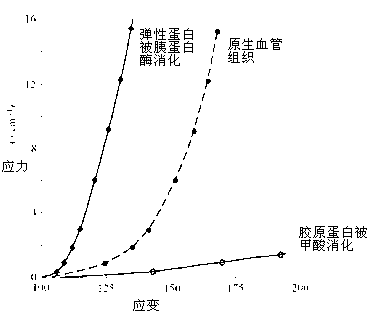

[0088] Such as Figure 12 As shown, the stress-strain curves of the fiber composite nonwoven mats with different ratios of elastic fibers and non-elastic fibers are different, so it can be known that the content ratio of elastic fibers and non-elastic fibers is the influence of the mechanical properties of fiber composite nonwoven mats one of the factors. in:

...

Embodiment 3

[0093] In the forming process of the fiber composite non-woven mat of the present invention, due to the different stretching degrees of the elastic nanofibers, the compression ratios of the non-elastic nanofibers are different. The influence of the compression rate of the non-elastic nanofiber layer on the mechanical properties of the fiber composite nonwoven mat was compared by making non-elastic nanofiber layers with different compression rates during the preparation process of the fiber composite nonwoven mat.

[0094] The elastic polymer formed by elastic nanofibers, the non-elastic polymer formed by non-elastic nanomaterials, and the preparation method of the elastic nanofiber layer and the non-elastic nanofiber layer are the same as in Example 1, that is, the elastic polymer used is the same as in Example 1. Described PU, nonelastic polymer are the PCL described in embodiment 1.

[0095] Set the original length and stretched length of PU nanofibers as L 0 and L 1 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression ratio | aaaaa | aaaaa |

| Compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com