Gas-seal and gas-liquid vibration damping recovery device used in immersion lithographic machine

A recovery device and air-sealing technology, which is applied in the field of flow field sealing and recovery devices, can solve problems such as liquid leakage, flow field edge instability, and sealing gas entrainment, so as to prevent liquid leakage, continuously and stably update, reduce fluctuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation process of the present invention will be described in detail below in conjunction with the drawings and embodiments.

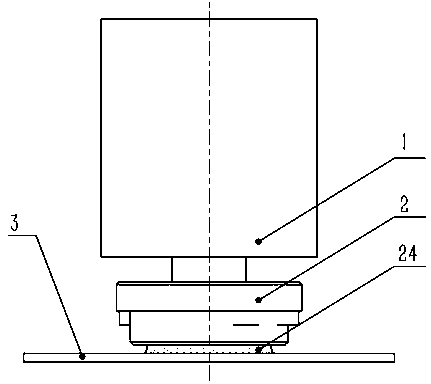

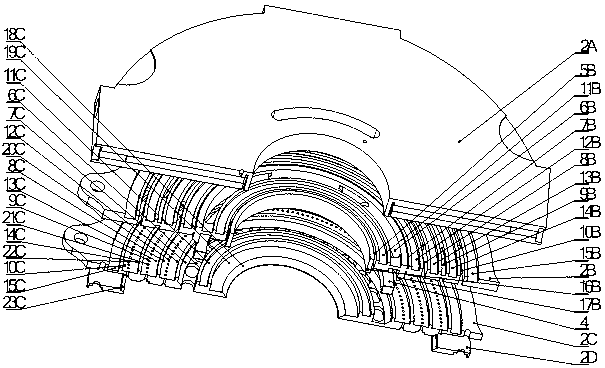

[0035] Such as figure 1 As shown, an air-tight and gas-liquid vibration damping recovery device is installed between the projection objective lens group 1 and the silicon wafer 3 in the immersion lithography machine; the gas-liquid damping recovery device includes a sealing and liquid injection recovery device 2. Porous medium 4; the sealing and liquid injection recovery device 2 consists of the upper end cover 2A of the immersion unit, the intermediate body 2B of the immersion unit, the lower end cover 2C of the immersion unit and the lower end cover accessory 2D of the immersion unit; wherein:

[0036] 1) Upper end cover 2A of the immersion unit:

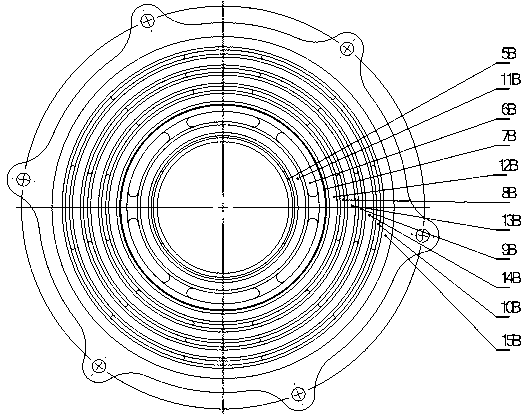

[0037] Such as Image 6 As shown, there is a central through hole in the upper end cover 2A of the immersion unit, and two symmetrical liquid injection tanks 5A are opened in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com