Process for preparing pramipexole dihydrochloride tablets

A preparation process, the technology of pramipexole tablet, which is applied in the direction of pill delivery, medical preparations containing active ingredients, organic active ingredients, etc., can solve the complex process, demanding process conditions, pramipexole dihydrochloride monohydrate Unstable tablet storage and other problems, to achieve the effect of low quality, high quality and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

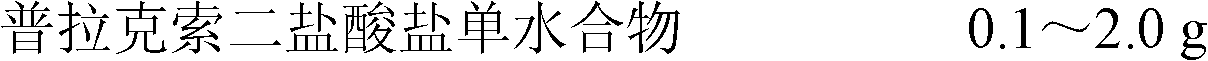

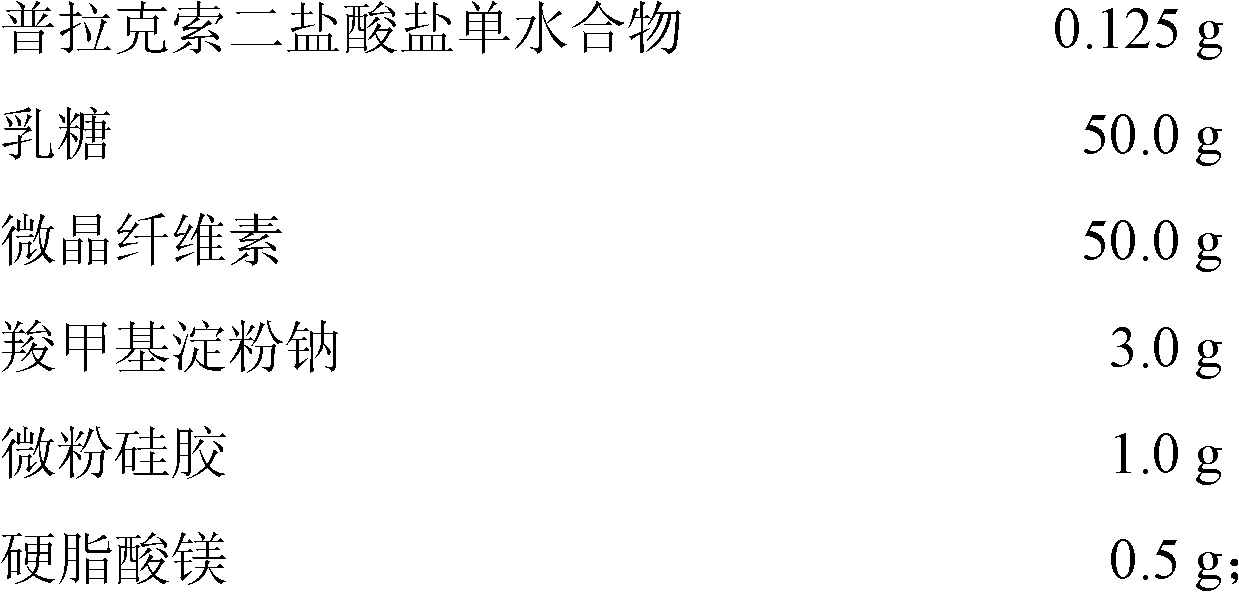

[0031] a) Ingredients

[0032] On the basis of 1000 dosage units, and each dosage unit contains 0.125 mg of pramipexole dihydrochloride monohydrate, weigh:

[0033]

[0034] b) Prepare the total mixture

[0035] ① Add pramipexole dihydrochloride monohydrate into a micronizer and pulverize until the particle size is not greater than 50 μm;

[0036] ②Put the pulverized pramipexole dihydrochloride monohydrate, binder (microcrystalline cellulose), and glidant (micropowder silica gel) into the mixer, mix for 5 minutes, and take a sample to detect its RSD≈8.5%; Mix for another 5 minutes, take a sample to detect its RSD ≈ 4%, release the material, and obtain material A;

[0037] ③ Add material A, filler (lactose) and disintegrant (sodium starch glycolate) into the mixer, mix for 5 minutes, release the material, and obtain material B;

[0038] ④ Add material B and lubricant (magnesium stearate) into the mixer and mix for 10 minutes to obtain the total mixed material;

[0039] c...

Embodiment 2

[0041] a) Ingredients

[0042] On the basis of 1000 dosage units, and each dosage unit contains 0.25 mg of pramipexole dihydrochloride monohydrate, weigh:

[0043]

[0044] For the rest of the content, refer to the description in Example 1.

Embodiment 3

[0046] a) Ingredients

[0047] On the basis of 1000 dosage units, and each dosage unit contains 0.5 mg of pramipexole dihydrochloride monohydrate, weigh:

[0048]

[0049] For the rest of the content, refer to the description in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com