Preparation method of high-purity rhodium iodide

A rhodium triiodide, high-purity technology, applied in the field of inorganic compounds, can solve the problems of low yield, complicated preparation method of rhodium triiodide, etc., and achieves high reactivity, increased mutual contact and collision, and high removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

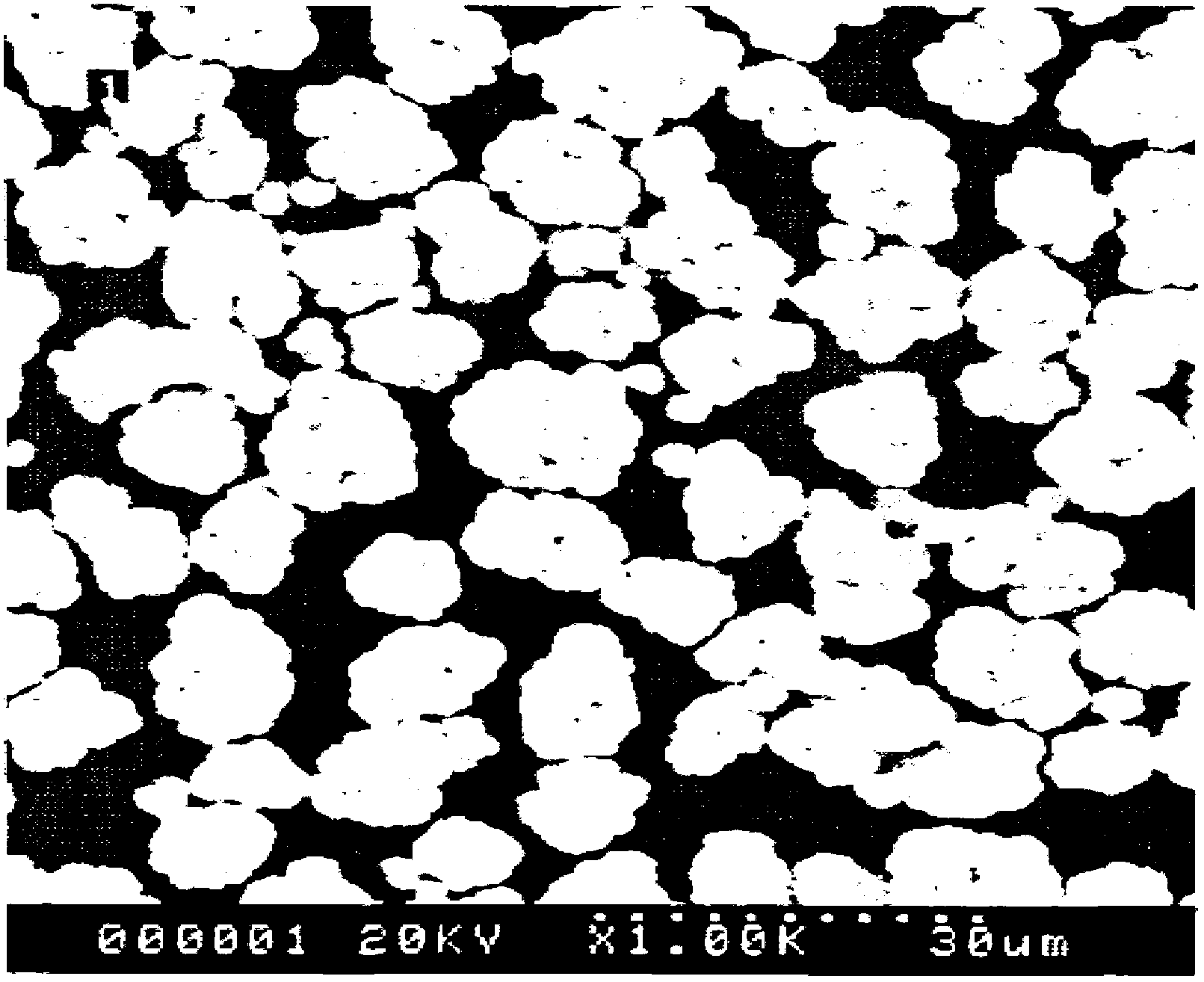

Image

Examples

Embodiment 1

[0035] Present embodiment is the preparation embodiment of high-purity rhodium triiodide, and concrete steps are:

[0036] S1. Take 98.4mL of rhodium trichloride aqueous solution with a rhodium concentration of 25g / L and 200g of HI solution with a concentration of 5% and place them in a microwave reactor, set the microwave power to 500W, and when the temperature reaches 100°C, continue the reaction at a constant temperature for 40min , to obtain a solution containing rhodium triiodide;

[0037] S2, after the end of the reaction, it is 20g / h of O that the flow rate is blown into the reaction solution 3 gas, maintain the reaction at 60°C, the generated I 2 Can further deepen the color of solution, stop reaction when the color of solution no longer deepens, and present embodiment shares 35min;

[0038] S3, the solid obtained after filtering the solution containing rhodium triiodide after the oxidizing gas treatment in step S2 is RhI 3 Crude product; washed with absolute ethano...

Embodiment 2

[0041] This embodiment is an example of preparing high-purity rhodium triiodide, and the preparation method is the same as in Example 1, specifically: 98.4 mL of rhodium trichloride aqueous solution with a rhodium concentration of 25 g / L and 65 g of HI solution with a concentration of 15% are placed In the microwave reactor, the microwave power was set at 150W, and when the temperature reached 80°C, the reaction was continued at a constant temperature for 60 minutes. O 3 Gas, maintain the reaction at 50°C for 30min. Then the reaction product is filtered; the obtained RhI 3 Wash with absolute ethanol until the washing solution is colorless and transparent. The washed material was dried at 120°C for 5 hours to obtain 11.521 g of high-purity rhodium triiodide, and the yield of rhodium iodide was 99.70%. The rhodium content measured by PerkinElmer7000DV inductively coupled plasma spectrometer is 20.92%, and the purity is high.

Embodiment 3

[0043]This embodiment is an example of preparing high-purity rhodium triiodide. The preparation method is the same as in Example 1, specifically: 98.4 mL of rhodium trichloride aqueous solution with a rhodium concentration of 25 g / L and 135 g of HI solution with a concentration of 7.5% are placed In the microwave reactor, the microwave power was set to 300W, and when the temperature reached 100°C, the reaction was continued at a constant temperature for 40 minutes. After the reaction was completed, the flow rate was 50g / h of O in the reaction solution. 2 Gas, maintain the reaction at 80°C for 30min. Then the reaction product is filtered; the obtained RhI 3 Wash with ethylene glycol until the washing solution is colorless and transparent. The washed material was dried at 120°C for 6 hours to obtain 11.533 g of high-purity rhodium triiodide, and the yield of rhodium iodide was 99.81%. The rhodium content measured by PerkinElmer7000DV inductively coupled plasma spectrometer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com