Ways to Extend Ion Source Life

An ion source and ion implanter technology, applied in the field of forming and/or accumulating deposits in ion source components, can solve the problems of reducing tool utilization, large tool downtime, etc., and achieve the effect of improving tool utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention relates to a method for implanting ions into a workpiece, which method improves or prolongs the ion source life of an ion implanter. Moreover, the method of the present invention provides improved life of the ion implanter source without the accompanying loss of equipment throughput.

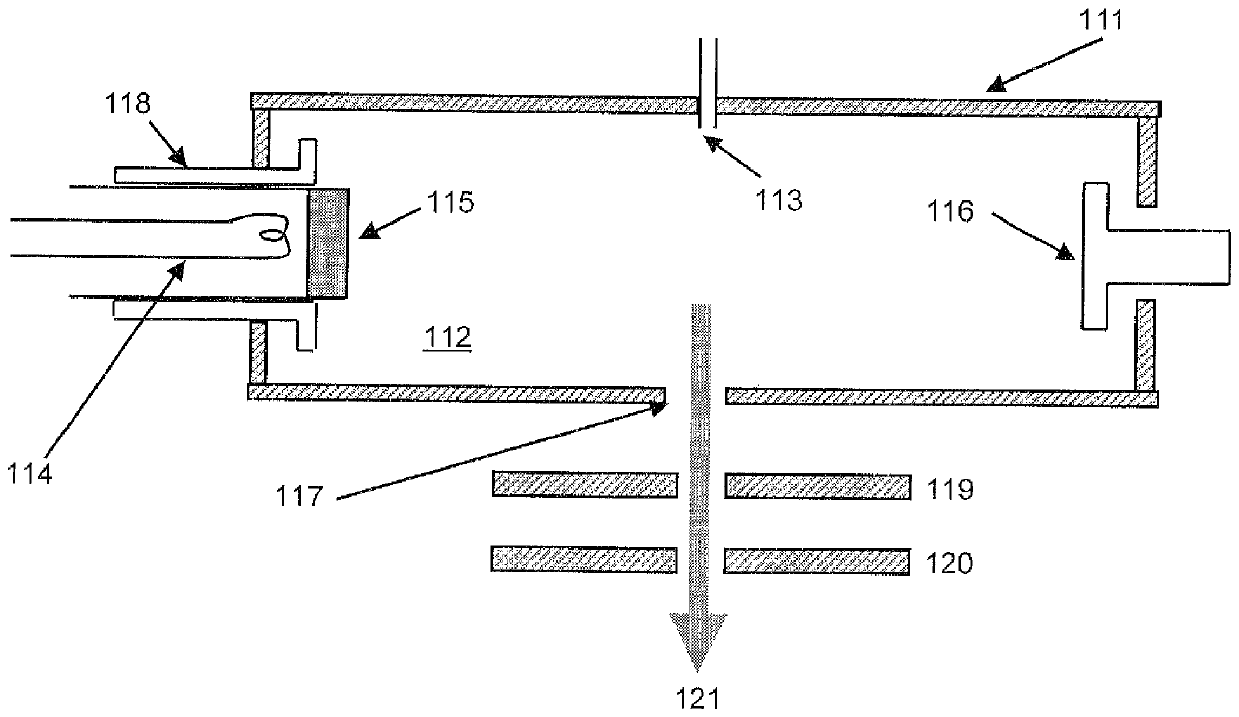

[0027] The present invention can be used to use a heated cathode type ion source (e.g. figure 1 IHC (Indirect Heated Cathode) ion source shown in) to operate the ion implanter. figure 1 The ion source shown in includes an arc chamber wall 111 that defines an arc chamber 112. In the operation of the injection machine, the source gas is introduced into the source chamber. The gas can be introduced into the source chamber through, for example, a gas feed port 113 on the chamber side. The ion source includes a filament 114. The filament is typically a tungsten-containing filament. For example, the filament may contain tungsten or a tungsten alloy containing at least 50% tungst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com