Composite hollow fiber film and preparation method thereof

A fiber membrane and hollow technology, which is applied in the field of composite hollow fiber membrane and its preparation, can solve the problems of complex forming process, poor tensile strength and low retention rate of composite membrane, and achieves easy control, high tensile strength and retention rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A composite hollow fiber membrane, comprising a polyvinylidene fluoride hollow fiber membrane base, a polyethylene glycol cross-linked layer is cross-linked on the polyvinylidene fluoride hollow fiber membrane base, and the polyethylene glycol cross-linked The layer is a spongy structure. The thickness of the polyethylene glycol cross-linked layer is 15um.

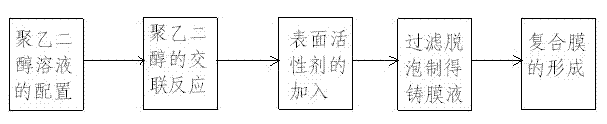

[0020] A preparation method of a composite hollow fiber membrane, such as figure 1 The shown technological process comprises the following steps:

[0021] 1) Dissolve polyethylene glycol in deionized water at 60°C, maintain the temperature and stir for 3 hours to prepare a polyethylene glycol solution with a mass percentage of 14%;

[0022] 2) Take 500 grams of polyethylene glycol solution and heat it to 80 ° C, stir and add 5 g of crosslinking agent maleic anhydride and 1.5 g of catalyst trimethylamine, continue to maintain the temperature and stir until the mixture is clear and transparent, and get Membrane sol...

Embodiment 2

[0028] A composite hollow fiber membrane, comprising a polyvinylidene fluoride hollow fiber membrane base, a polyethylene glycol cross-linked layer is cross-linked on the polyvinylidene fluoride hollow fiber membrane base, and the polyethylene glycol cross-linked The layer is a spongy structure. The thickness of the polyethylene glycol cross-linked layer is 20um.

[0029] A preparation method of a composite hollow fiber membrane, such as figure 1 Shown technological process is characterized in that: comprises the following steps:

[0030] 1) Dissolve polyethylene glycol in deionized water at 70°C, maintain the temperature and stir for 2 hours to prepare a polyethylene glycol solution with a mass percentage of 16%;

[0031] 2) Take 500 grams of polyethylene glycol solution and heat it to 70 °C, stir and add 10 g of cross-linking agent maleic anhydride and 3 g of catalyst trimethylamine, continue to maintain the temperature and stir until the mixed solution is clear and transp...

Embodiment 3

[0037] A composite hollow fiber membrane, comprising a polyvinylidene fluoride hollow fiber membrane base layer 1, a polyethylene glycol crosslinking layer 2 is cross-linked on the polyvinylidene fluoride hollow fiber membrane base layer 1, and the polyethylene glycol The alcohol cross-linked layer 2 has a sponge-like structure. The thickness of the polyethylene glycol cross-linked layer 2 is 25um.

[0038] A preparation method of a composite hollow fiber membrane, such as figure 1 The shown technological process comprises the following steps:

[0039] 1) Dissolve polyethylene glycol in deionized water at 80°C, maintain the temperature and stir for 2.5 hours to prepare a polyethylene glycol solution with a mass percentage of 18%;

[0040] 2) Take 500 grams of polyethylene glycol solution and heat it to 85°C, stir and add 15g of cross-linking agent maleic anhydride and 6g of catalyst trimethylamine, continue to maintain the temperature and stir until the mixed solution is cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com