Nanometer ferrosilicon composite particle of three-layer nuclear shell structure and preparing method and application thereof

A technology of core-shell structure and composite particles, applied in chemical instruments and methods, contaminated groundwater/leachate treatment, water/sludge/sewage treatment, etc., can solve the problems of inappropriate particle size and high carrier cost, and achieve Easy separation, simple process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

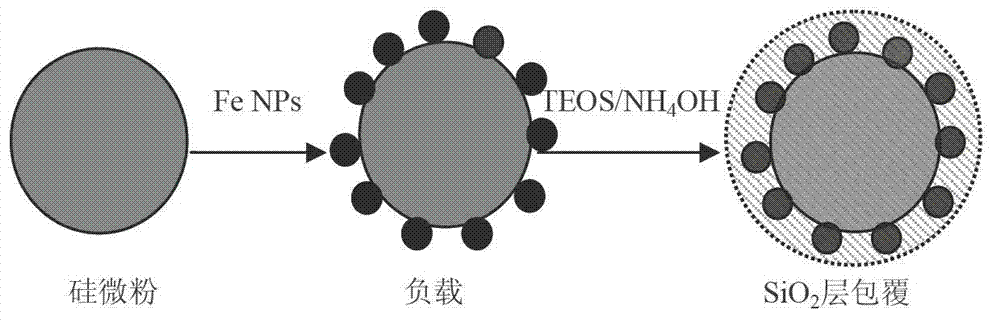

[0029] see figure 1 , is the nano-iron-silicon composite particle SF-Fe with three-layer core-shell structure of the present invention 0 SiO 2 The preparation flow chart. It mainly includes three processes. Firstly, the modified silicon powder is prepared. Through acid modification, the hydroxyl groups on the surface of the silicon powder are strengthened. Secondly, the zero-valent nano-iron is uniformly distributed on the surface of the silicon powder, and then the prepared SF-Fe 0 Dispersed in ethyl orthosilicate solution, by gel-sol method, in SF-Fe 0 The surface is uniformly coated with a layer of SiO 2 , and finally washed with deionized water and absolute ethanol to obtain SF-Fe 0 SiO 2 Composite particles.

[0030] The specific process is as follows.

[0031] (1) Preparation of modified silica powder:

[0032] Prepare a 13g / L silicon micropowder slurry, then add hydrochloric acid solution, adjust the pH to 6.5, settle naturally for 2.5 hours, take the upper laye...

Embodiment 2

[0044] This embodiment is preparing black SF-Fe 0 solution, the reactant uses NaBH 4 Solution replaces KBH in embodiment 1 4 solution, and other steps are the same as in Example 1.

Embodiment 3

[0046] (1) Preparation of modified silica powder:

[0047] Prepare a 13g / L silicon micropowder slurry, then add hydrochloric acid solution, adjust the pH to 6.5, settle naturally for 2.5 hours, take the upper layer slurry, and centrifuge to obtain modified silicon micropowder;

[0048] (2) Deoxygenation:

[0049] Disperse 0.2g modified silica powder in 50ml FeCl 3 In the aqueous alcohol solution, wherein, the volume ratio of alcohol to water is 3:7, so that the molar concentration of iron ions is 0.02mol / L, nitrogen gas is introduced to remove oxygen for 35 minutes, and then mechanically stirred for 15 minutes to mix evenly to obtain a mixed solution;

[0050] (3) Preparation of SF-Fe 0 Solution:

[0051] Add 0.17g KBH dropwise to the mixed solution under mechanical stirring 4 solution, and reacted for 40min to obtain a black nano-iron solution;

[0052] (4) Preparation of SF-Fe 0 particle:

[0053] Separation of the above SF-Fe by magnetic separation 0 particles, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com