Reinforced denitrification method for three-dimensional electrode biological film

A three-dimensional electrode and biofilm technology, applied in chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc., can solve the problems affecting the water quality of the system, and achieve the improvement of excessive pH difference and NO2--N Accumulation, effect of strong pH buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

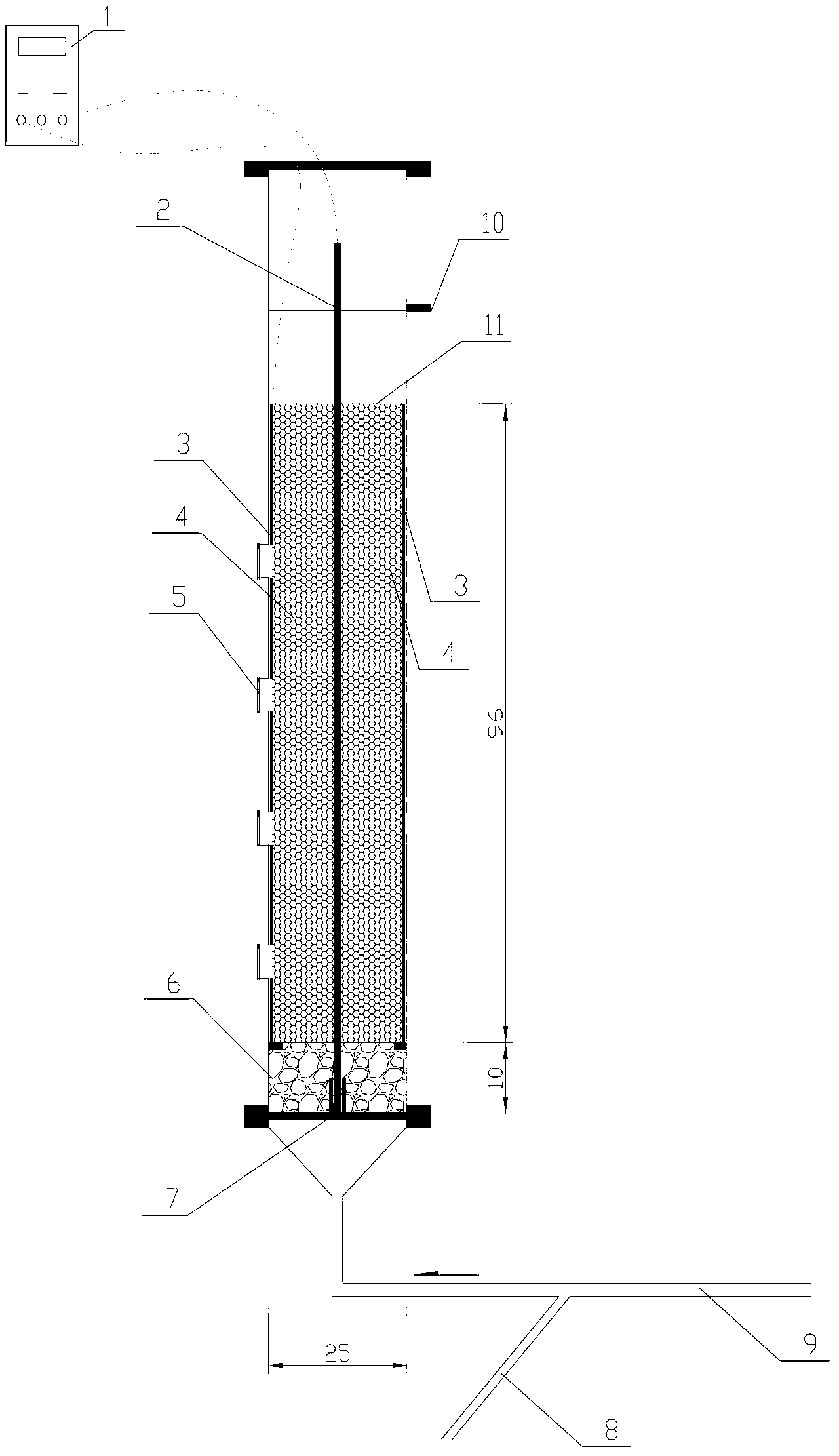

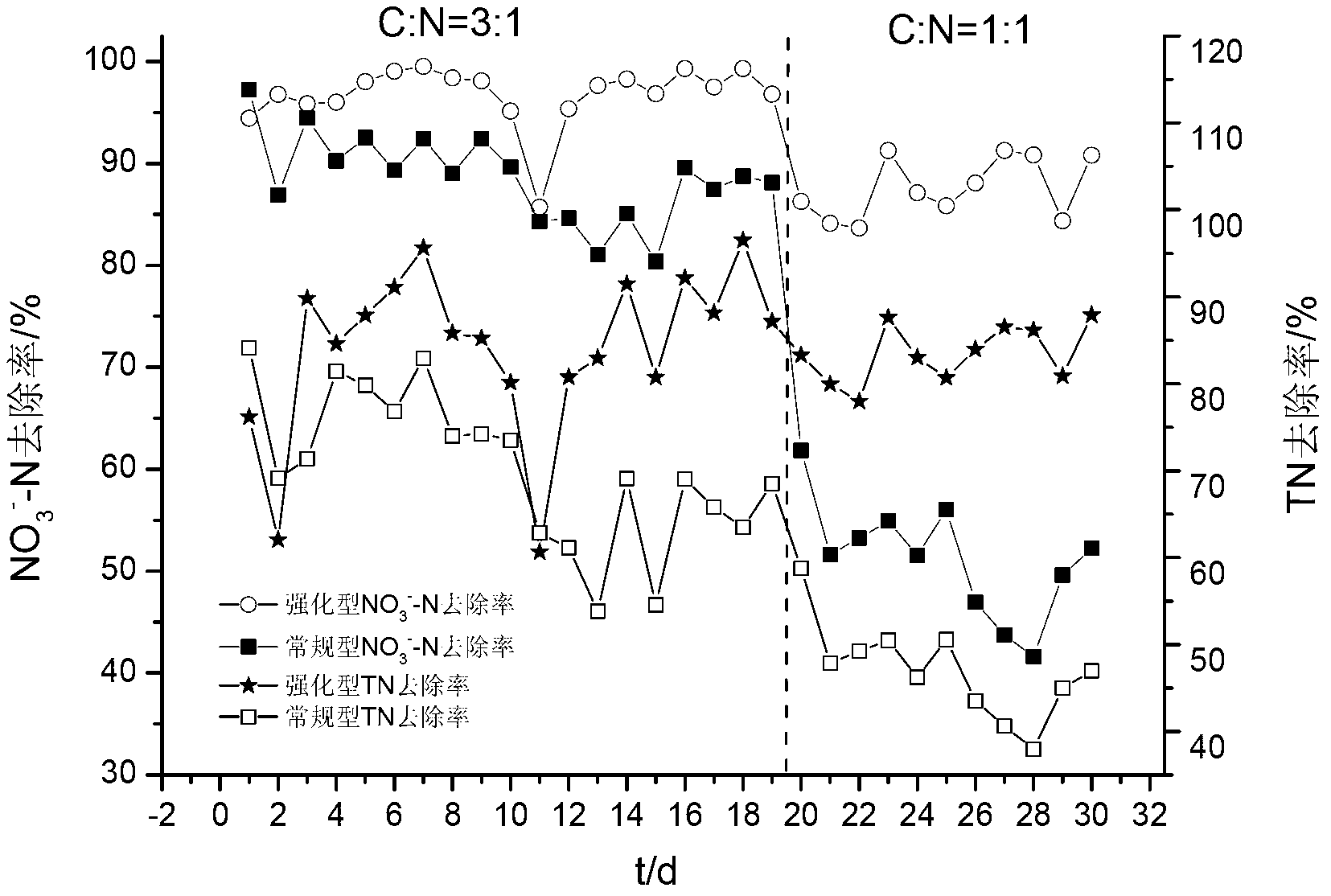

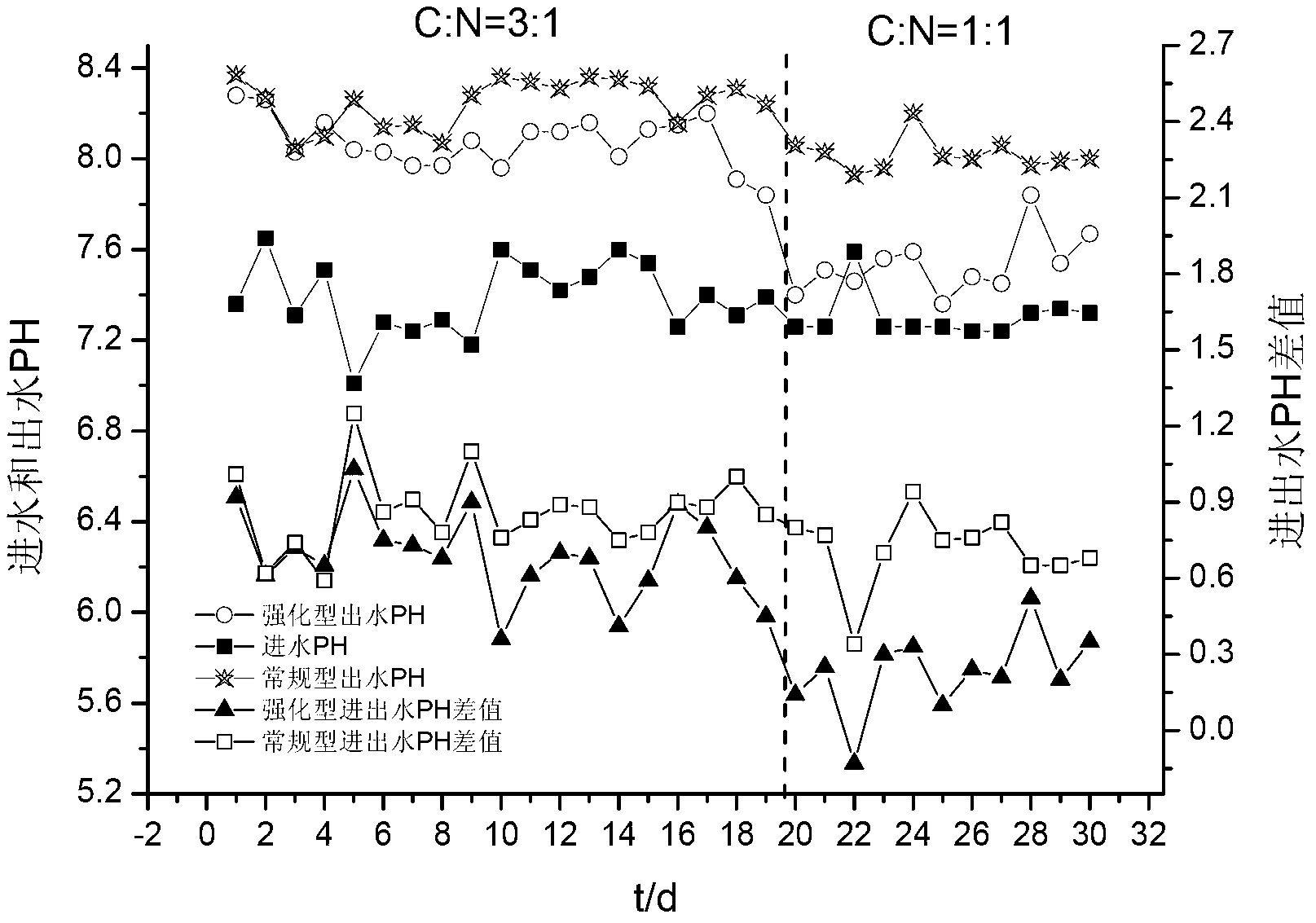

[0032] Three-dimensional electrode bioenhanced denitrification process and conventional three-dimensional electrode biofilm process were used to treat sewage with a carbon, nitrogen and phosphorus ratio (the mass concentration ratio of COD to nitrogen and phosphorus) of 30:10:1 and a pH of 7.0-7.5. Keep the electrode current at 60mA, the hydraulic retention time at 12h, and the temperature at 15-22°C. Determination of TN and NO in influent and effluent water every day 3 - -N, NO 2 - -N, pH and SO 4 2- . After 19 days of stable operation of the two processes, the average removal rate of TN in the three-dimensional electrode biofilm enhanced denitrification process was 85.55%, and the NO 3 - The average removal rate of N is 98.49%; the average pH value of the effluent water is 8.07, and the average pH difference between the influent and effluent water is 0.64; NO 2 - The average accumulation of -N is 3.90mg / l, and the effluent SO 4 2- The average accumulation amount is...

example 2

[0034] Three-dimensional electrode bioenhanced denitrification process and conventional three-dimensional electrode biofilm process were used to treat sewage with a carbon-nitrogen-phosphorus ratio of 10:10:1 and a pH of 7.0-7.5. Keep the electrode current at 60mA, the hydraulic retention time at 12h, and the temperature at 15-20°C. After 11 days of stable operation of the two processes, the average removal rate of TN in the three-dimensional electrode biofilm process for enhanced autotrophic denitrification was 81.34%, and NO 3 - The average removal rate of -N was 84.23%; the average pH value of the effluent water was 7.64, and the average pH difference between the influent and effluent water was 0.29; NO 2 - The average accumulation of -N is 0.99mg / l, and the effluent SO 4 2- The average accumulation of nitrogen is 128.8mg / L, and the average removal rate of total nitrogen in the conventional three-dimensional electrode biofilm process is 47%. 3 - - The average removal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com